Method of super hydrophobic orbit regulating air bubble division

A bubble splitting and super-hydrophobic technology, applied in the field of multiphase flow, can solve problems such as pipeline blockage and inability to generate bubbles, and achieve the effects of low cost, simple preparation, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and example.

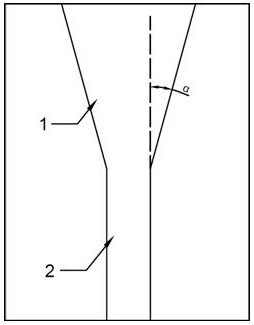

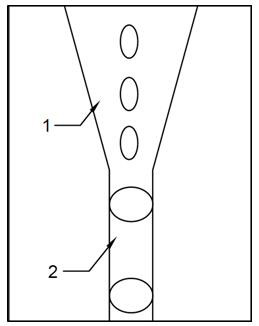

[0027] In this embodiment, a glass plate is used as the substrate, and a layer of superhydrophobic coating is sprayed with a contact angle of 160°. The excess part of the edge of the superhydrophobic coating is removed by wiping, so that the superhydrophobic track has an equal-width section 2 and a diffusion section 1, wherein the medium-width section The two sides of the track are always parallel, the distance between the two sides is 1 mm, and the angle α between the diffusion section and the equal-width section is 1°.

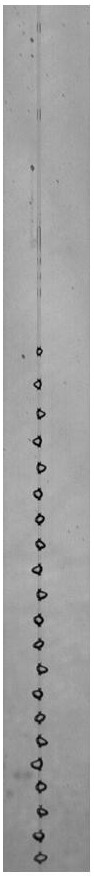

[0028] When the water body is submerged in the superhydrophobic track, the air bubbles float freely under the buoyancy. Under the action of tension, a stable non-spherical shape is formed, which is finally stably adsorbed on the equal-width track, and moves linearly along the equal-width track under the action of buoyancy and superhydrophobic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com