A method for diamond single-point car-assisted ion beam polishing of metal mirrors

A technology for polishing metal and diamond, which is applied in the field of ion beam polishing of metal mirrors assisted by diamond single-point turning, which can solve the problems that the processing accuracy is difficult to meet the requirements of high-quality optical systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

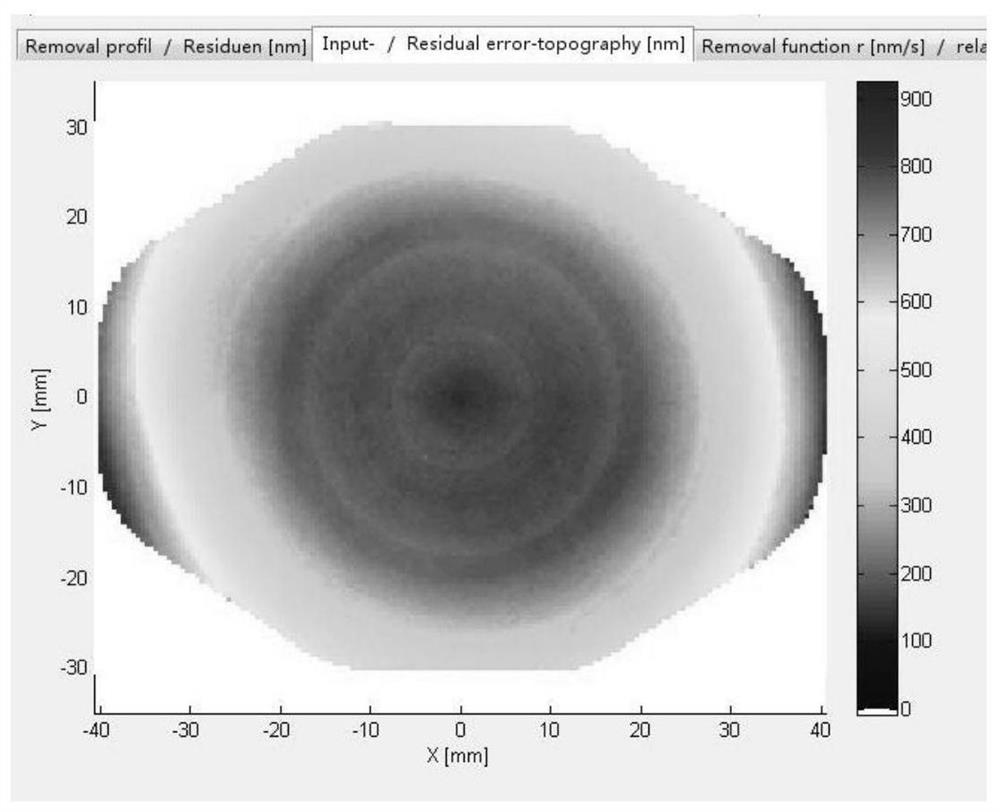

[0035] Aluminum mirror processing

[0036] Aluminum alloy reflector, size 62mm*82mm

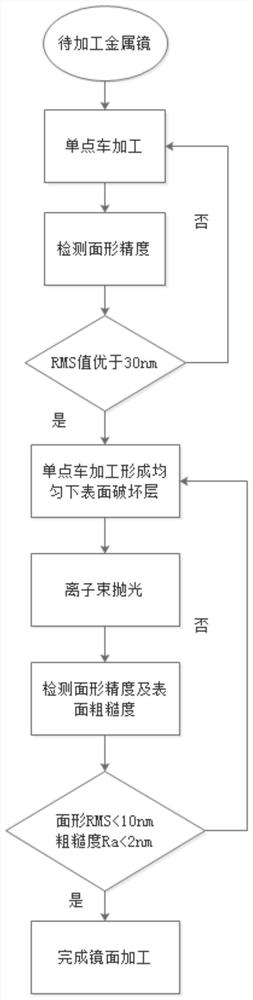

[0037] Its processing flow is as follows:

[0038] 1) Single-point lathe processing until the mirror surface error rms value is 28.2nm, PV value is 850nm, surface roughness Ra1.95nm, and the thickness h of the damaged layer on the lower surface that needs to be produced is greater than 850nm;

[0039] 2) Adjust the working parameters of diamond single-point turning, and the processing parameters of single-point turning are as follows:

[0040] Speed 1200rpm

[0041] x feed is 3mm / min

[0042] Penetration depth 3μm

[0043] 3) Single-point car removes material uniformly on the mirror surface, the material removal thickness is 5 μm, and the thickness h of the damaged layer on the lower surface is 920nm, satisfying h≥PV;

[0044] 4) Detect the mirror surface error RMS value of 29.1nm to prepare for the next step of ion beam processing;

[0045] 5) Set the working parameters of ion beam p...

Embodiment 2

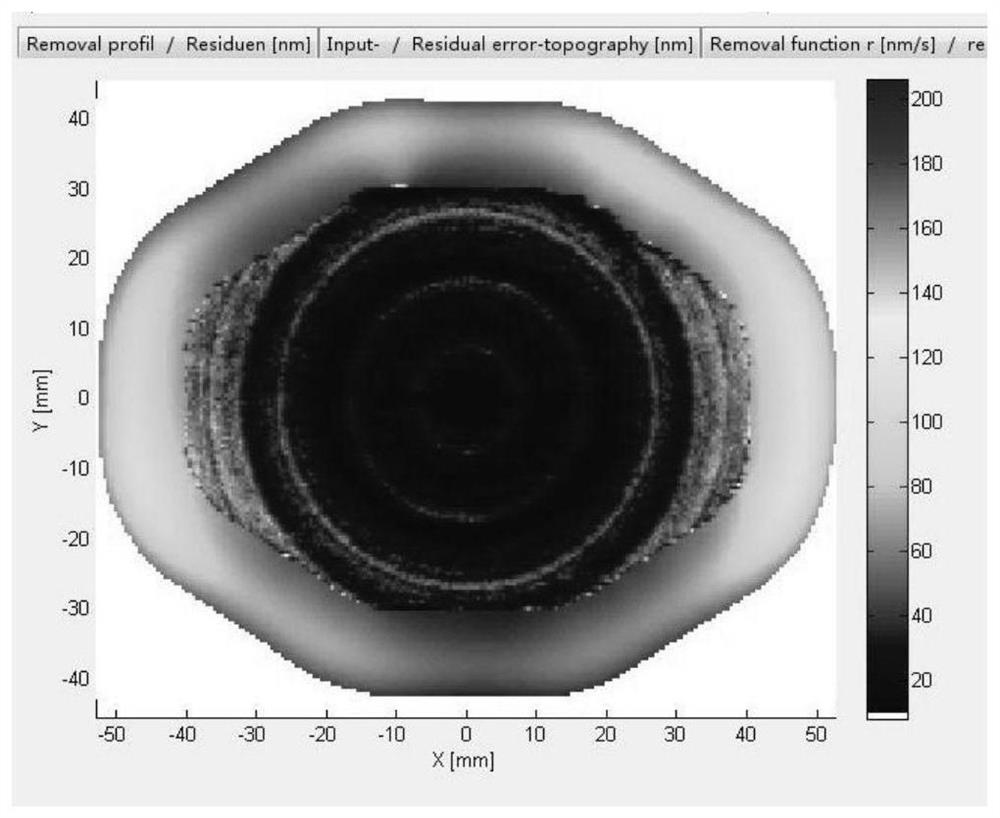

[0049] Using this method to process a 132mm diameter aluminum alloy convex reflector

[0050] 1) Single-point lathe processing until the mirror surface error rms value is 29.6nm, PV value is 1040nm, surface roughness Ra2.01nm, and the thickness h of the damaged layer on the lower surface that needs to be produced is greater than 1040nm;

[0051] 2) Adjust the working parameters of diamond single-point turning, and the processing parameters of single-point turning are as follows:

[0052] Speed 1800rpm

[0053] x feed is 2mm / min

[0054] Penetration depth 2μm

[0055] 3) Single-point car removes material evenly on the mirror surface, the material removal thickness is 6 μm, and the thickness h of the damaged layer on the lower surface is 1100nm, satisfying h≥PV;

[0056] 4) Detect the mirror surface error RMS value of 30.5nm, to prepare for the next step of ion beam processing;

[0057] 5) Set the working parameters of ion beam polishing: the ion energy is 800ev, the gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com