Automatic levelling, quick abutting and moving type full-automatic screwdriving machine

A technology of locking screw machine and automatic leveling, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low screw efficiency and missing screws, and achieve high work efficiency, prevent missing screws, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

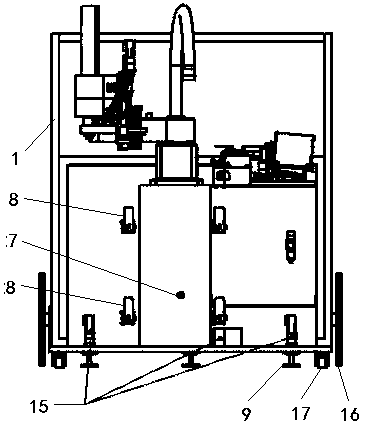

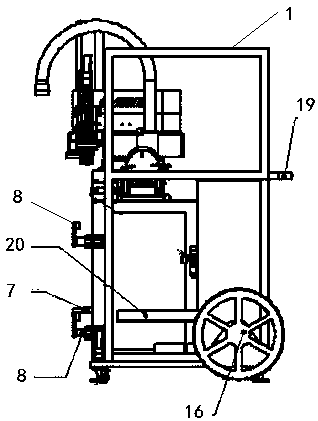

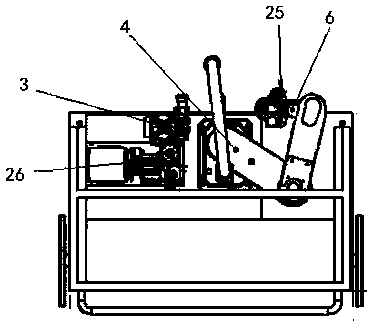

[0034] Accompanying drawing is a kind of specific embodiment of the present invention.

[0035] The self-leveling fast docking mobile automatic screw locking machine of the present invention includes a host and a workbench 10 for use in conjunction with each other. The host includes two screw locking machines with the same or similar main body structure, which are respectively the main machine 13 on the sky side and the main machine on the ground side. 14;

[0036] Its host computer includes a frame 1, and a feeding mechanism installed on the frame, a nail picking mechanism 3, a robot arm 4, an electric control cabinet 5, and the robot arm is connected with a locking mechanism 6;

[0037] It is characterized in that: the center positioning column 7 and the clamping and fixing mechanism 8 are installed on the frame; the height-adjustable feet 9 are installed on the bottom of the frame, and the height can be adjusted and leveled through the feet;

[0038] Two locking screw mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com