Detection robot, system and operation method of double-split carbon fiber wire

A carbon fiber wire, double-split technology, applied in manipulators, overhead line/cable equipment, material analysis using radiation, etc., can solve the problems of many restrictions, no obstacle-crossing function, and inconvenient damage to the inner core of double-split carbon fiber wires , to achieve high safety performance, good flaw detection effect, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

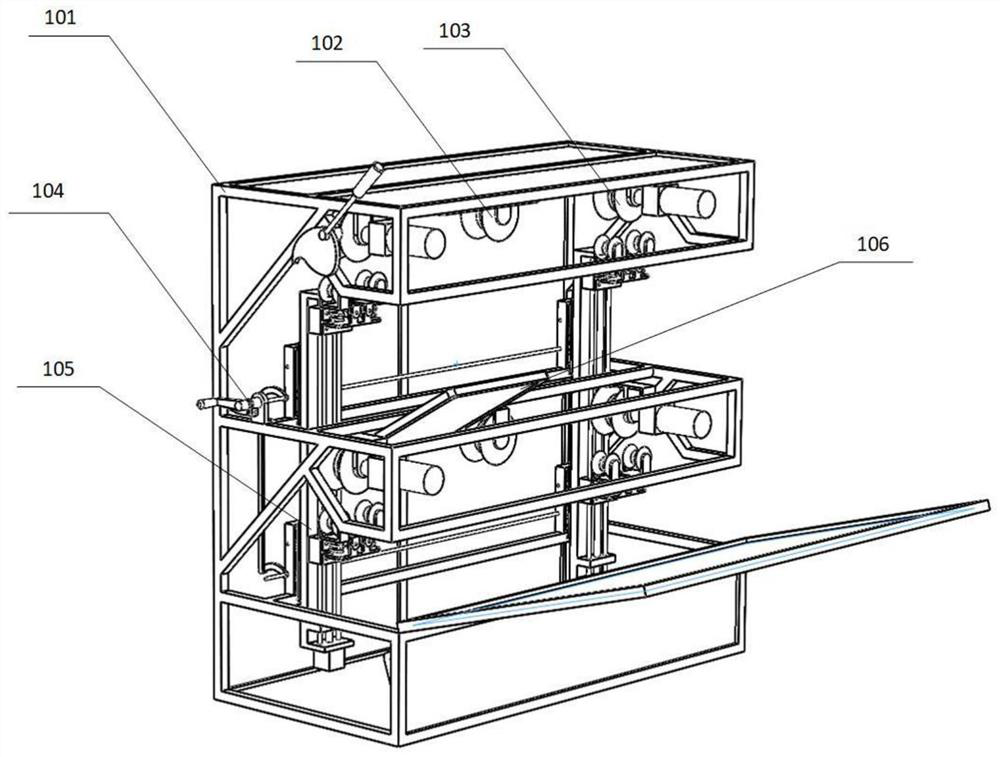

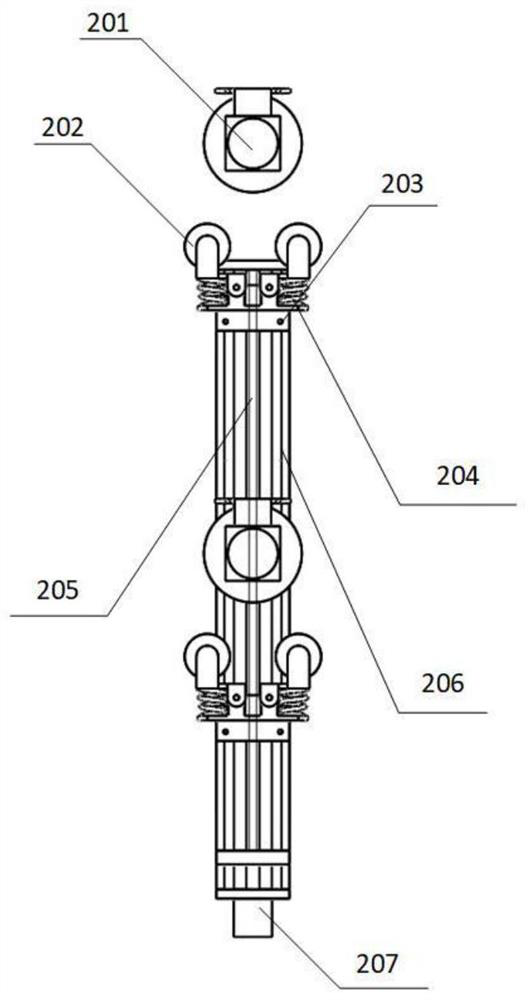

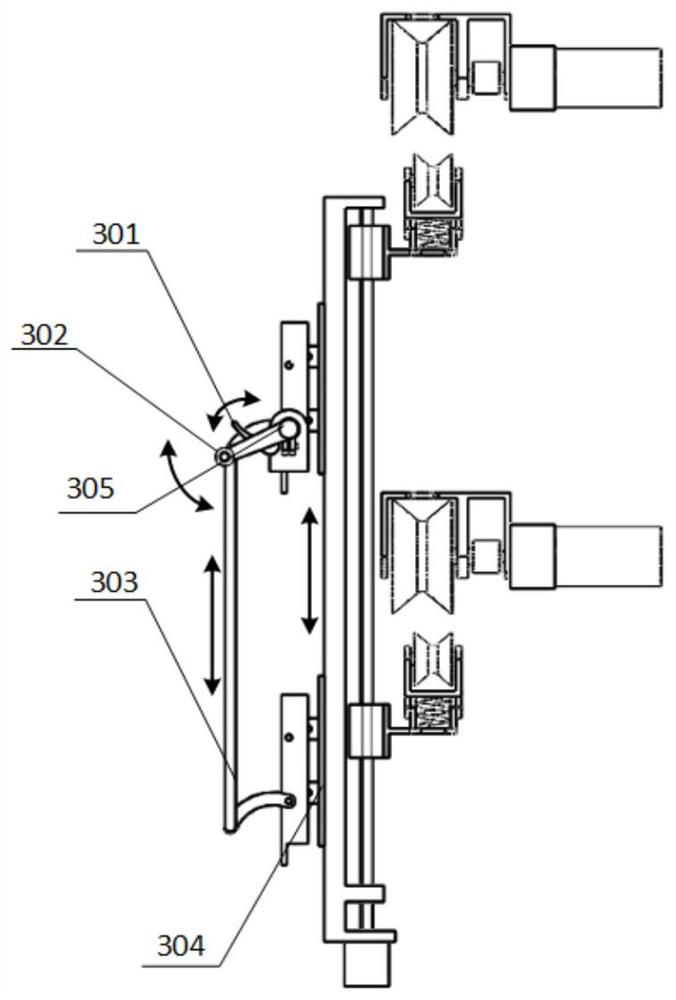

[0030] like Figure 1-2 As shown, the machine includes a body frame 101 , a support wheel 102 , a driving wheel device 103 , a clamping device 104 , a clamping device 105 and a flaw detection device 106 . The body frame 101 is an aluminum alloy frame, which adopts a wrapped structure. The aluminum alloy frame includes an upper frame and a lower frame. Both the upper frame and the lower frame are provided with a driving wheel device 103 and a supporting wheel 102. The driving wheel device 103 includes a driving wheel and a driving motor. , the driving wheel is driven by the driving motor 201 to provide the power for the robot to walk. The driving wheel device 103 and the supporting wheel 102 on each layer of frame are distributed according to the direction of the wire to be measured. A supporting wheel 102 is arranged between the two driving wheels, and the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com