Box-type polyurethane foam preparation method

A polyurethane foam, box-type technology, applied in the field of box-type polyurethane foam preparation, can solve the problems of waste, high slice weight, inconsistent quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

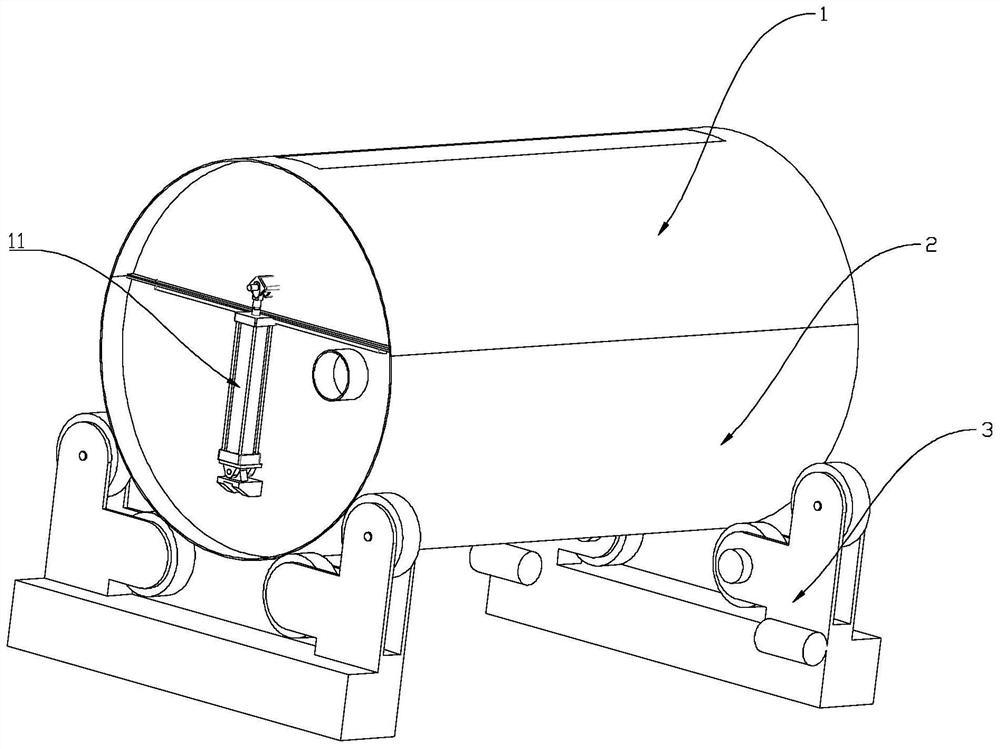

[0048] see figure 1 with Image 6 , the present invention provides a kind of box-type polyurethane foam preparation method, and this method is mainly based on the application of a kind of foaming device, and this foaming device comprises foaming box, cylindrical sealing box and rotating device 3, and sealing box is installed on the rotary On the device 3, the foaming box is arranged in the sealed box.

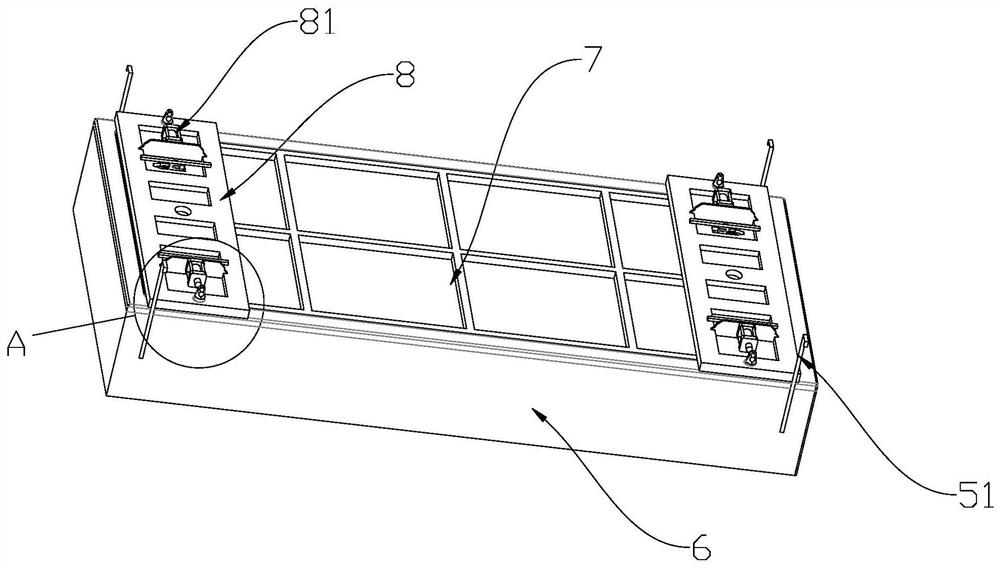

[0049] One deck release film needs to be laid in the foam box 4 (function: to facilitate the demoulding of the later stage foam).

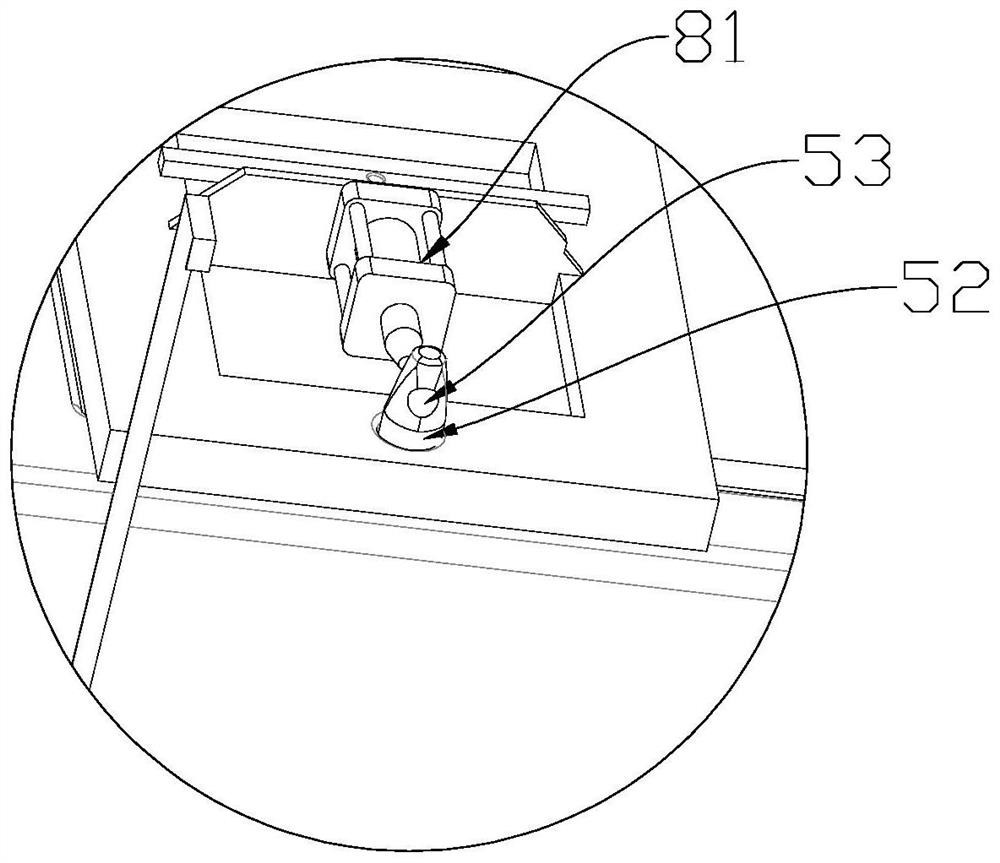

[0050] On the basis of retaining the demoulding film laid on the bottom of the original foaming box 4, an edge-lifting film 6 that can move up and down is added in addition. This edge-lifting film 6 is annular, and matches with the inner wall of the foaming box 4 ), but the height

[0051] Simply put, the edge-lifting film 6 can move upwards under artificial control (moving to the highest height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com