USB flash drive assembly detection production line

An assembly inspection and production line technology, applied in storage devices, transportation and packaging, and other manufacturing equipment/tools, etc., can solve problems such as limiting enterprise production efficiency, increasing enterprise capital budget, and affecting enterprise competitiveness, so as to improve assembly and inspection Efficiency, meet the needs of production assembly, simple and efficient assembly and testing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

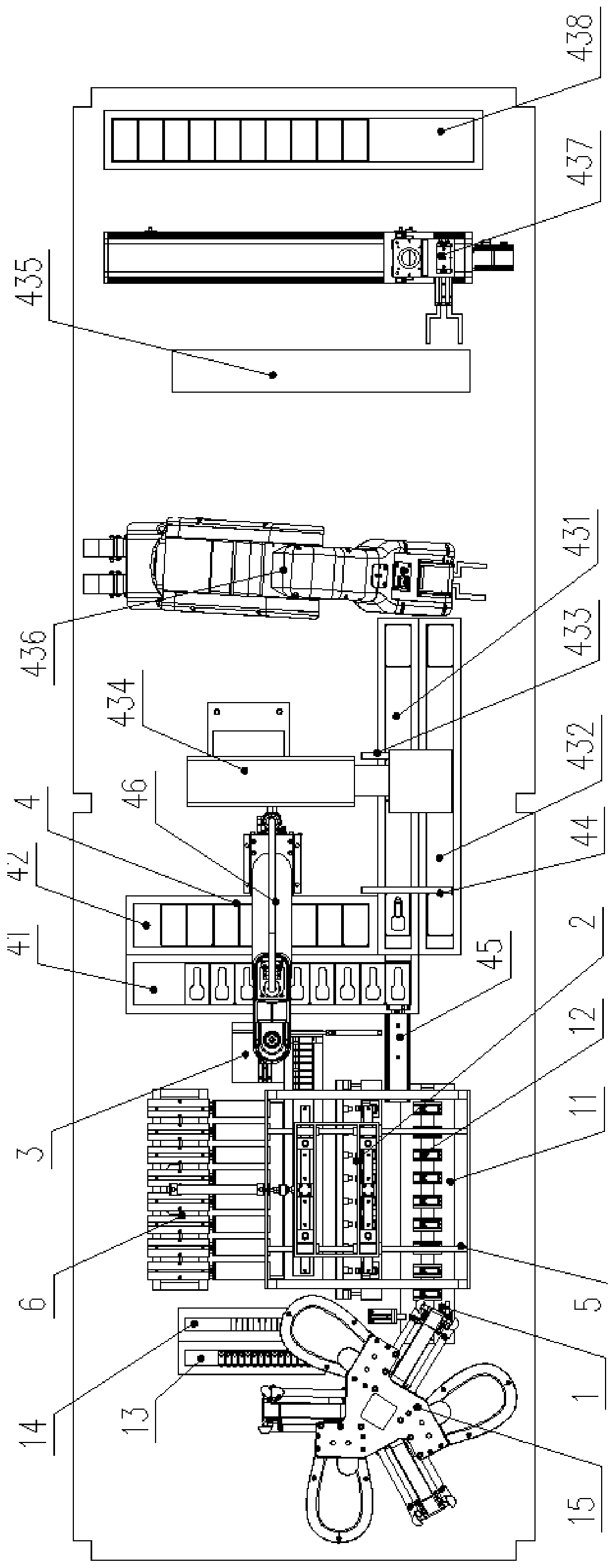

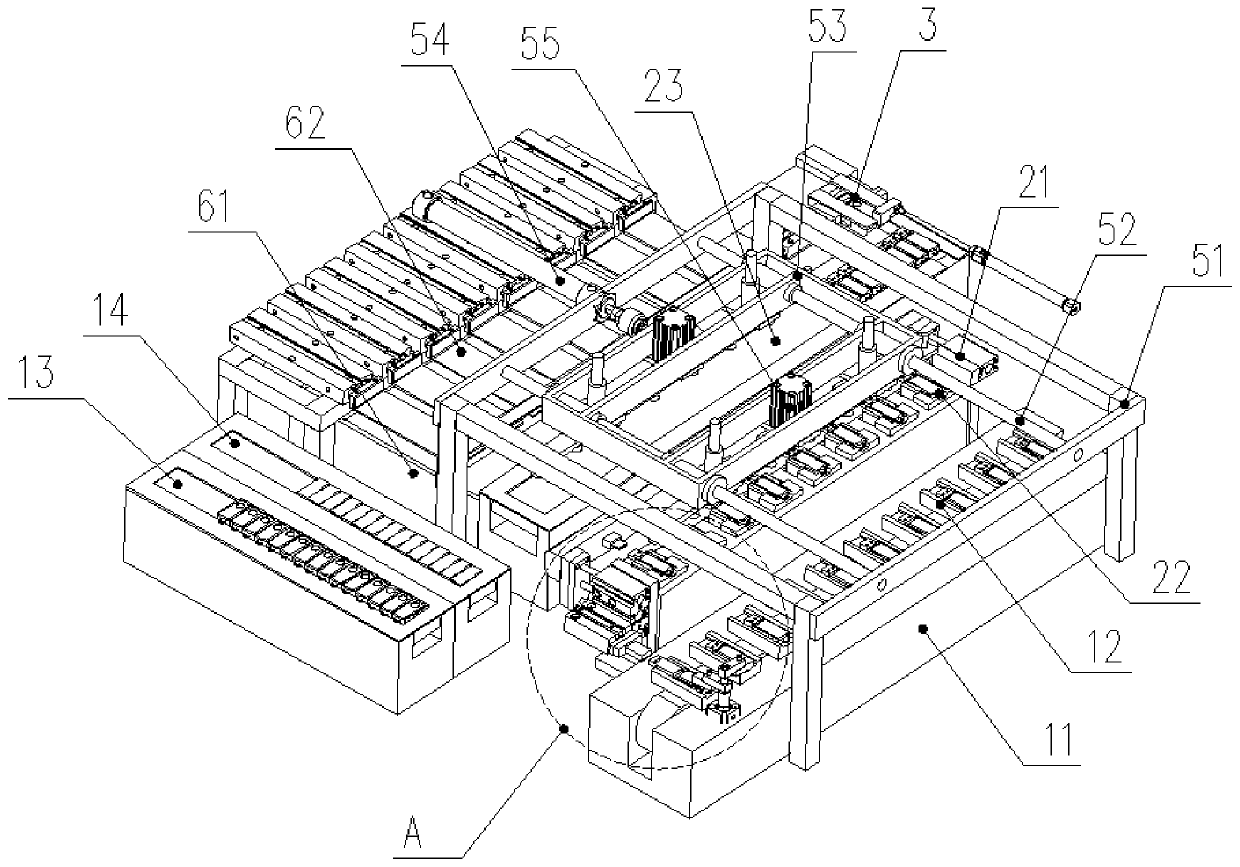

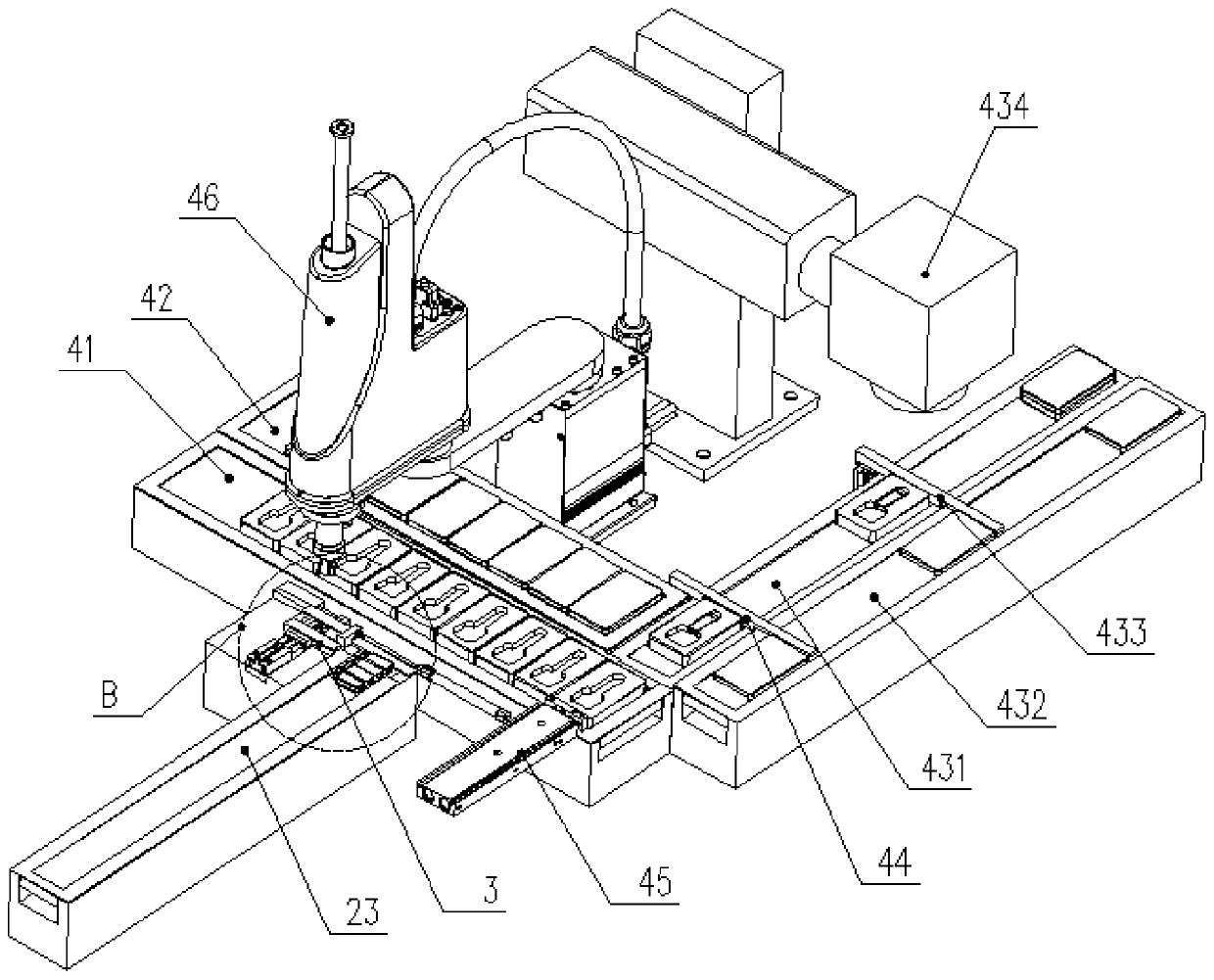

[0026] Such as Figures 1 to 5 As shown, the U disk assembly and inspection production line of the present invention includes an assembly station 1, a performance inspection station 2, a spinning station 3 and a packaging station 4 arranged in sequence.

[0027] The assembly station 1 includes a rotary shell conveying line 13 for the transportation of the rotating shell member, a disk core conveying line 14 and a first conveying line 11 for the transportation of the U disk core components, the rotary shell conveying line 13, A loading robot 15 is arranged between the core conveying line 14 and the first conveying line 11; each of the above conveying lines adopts a belt transmission form. The first conveying line 11 is provided with at least two arranging s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com