Bottle clamping mechanism and bottle fetching device

A bottle clamping and clamping section technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large occupied space and small number of sampling bottles, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

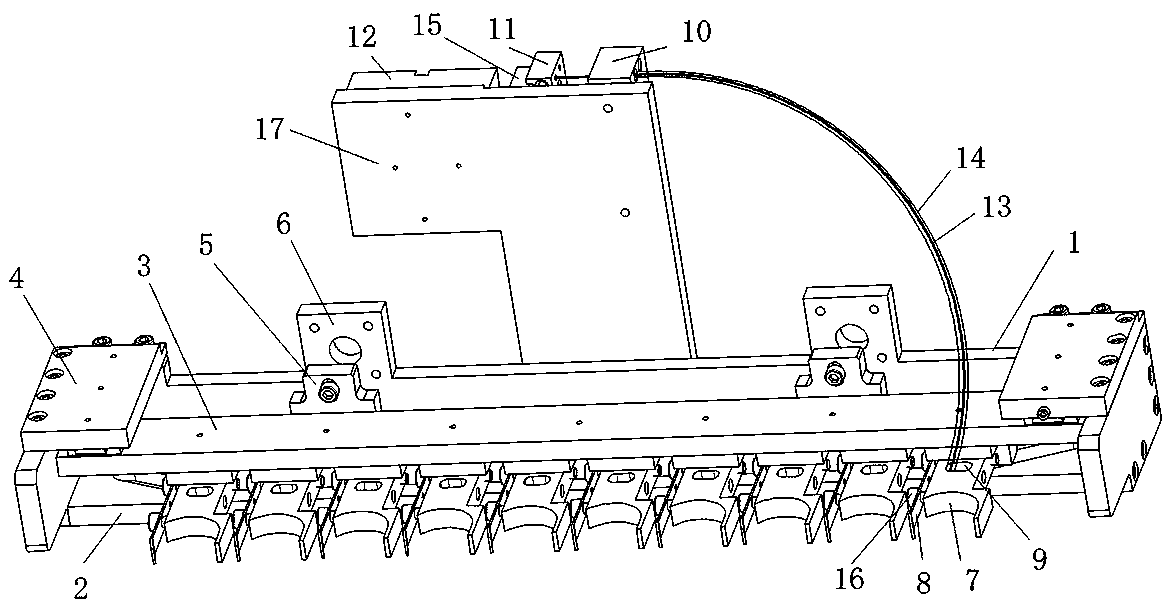

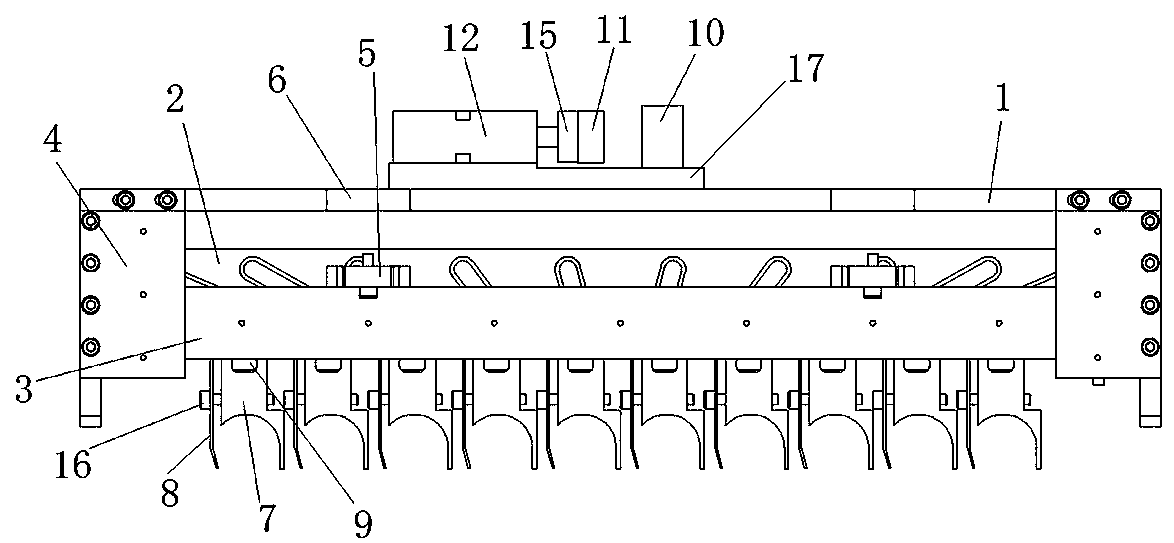

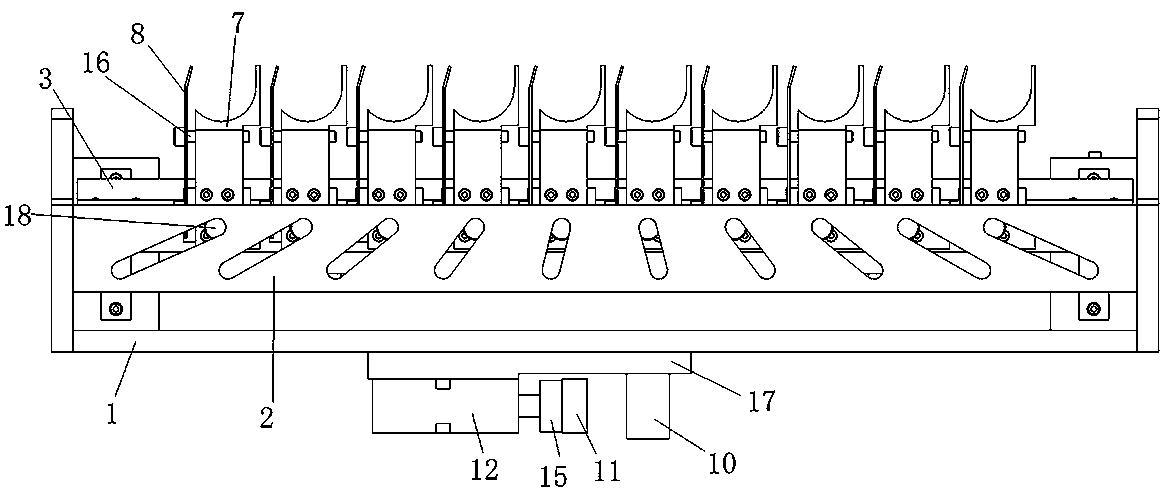

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The specific embodiment of bottle getting device of the present invention, as figure 1 and figure 2As shown, the bottle fetching device includes a base 1, and the base 1 is provided with a drive plate 3 and a guide plate 2 arranged at intervals along the up and down direction, and the drive plate 3 and the guide plate 2 both extend along the left and right directions. The guide plate 2 is fixed on the base 1 through its two ends, and the drive plate 3 is reciprocally guided and slidably assembled on the base 1 along the front and rear directions. The bottle taking device also includes a plurality of bottle clamping mechanisms, each clamping bottle mechanism is arranged at intervals along the left and right directions, the front end of the clamping bottle mechanism is a clamping end arranged overhangingly, and the rear end is assembled between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com