Glue cylinder and glue feeding method thereof

A glue tank and glue feeding technology, applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as corrosion, harsh working environment, false alarms, etc., and achieve the effects of easy maintenance, prevention of cylinder explosion, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A glue injection device and a glue feeding method of the present invention are described in conjunction with the accompanying drawings.

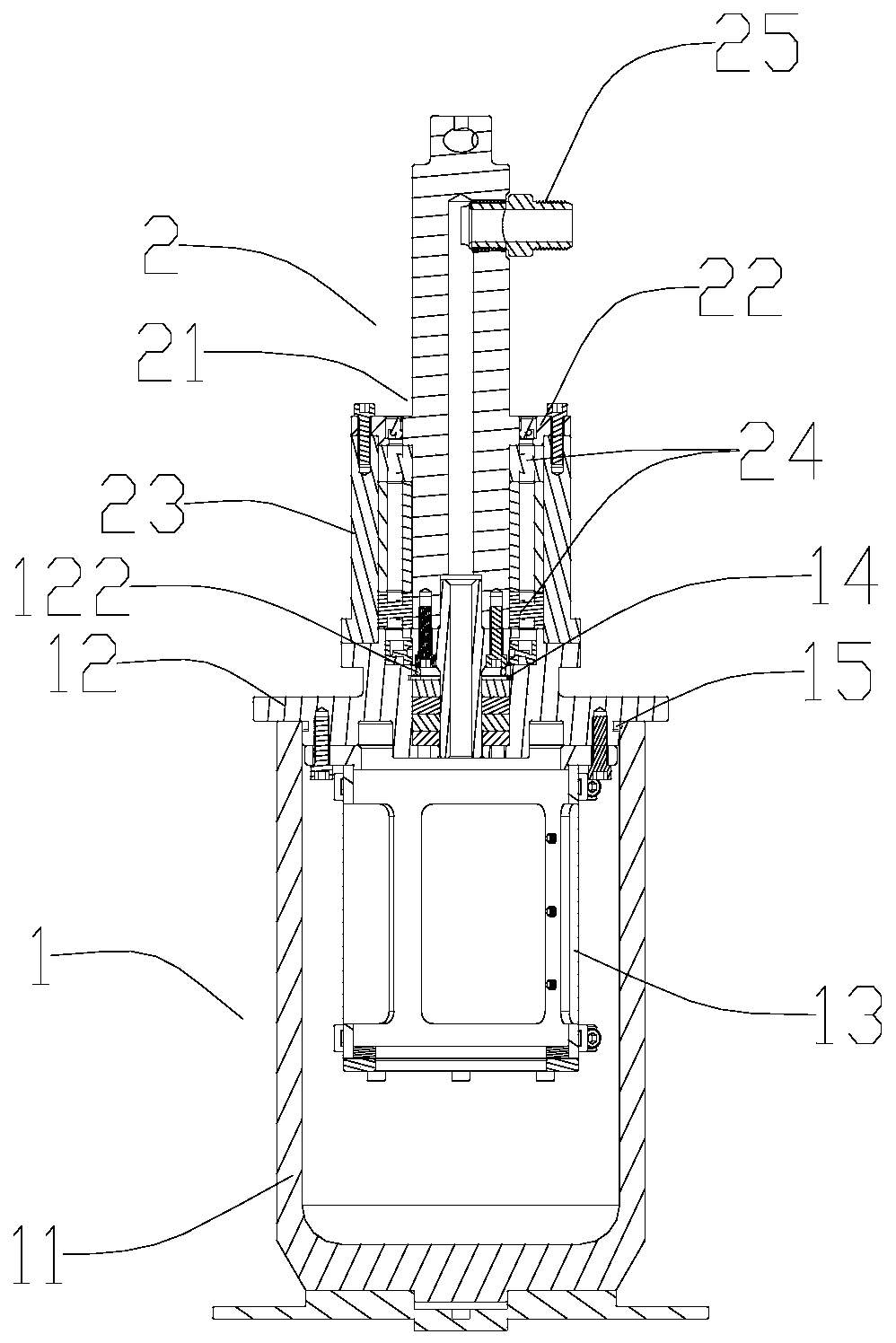

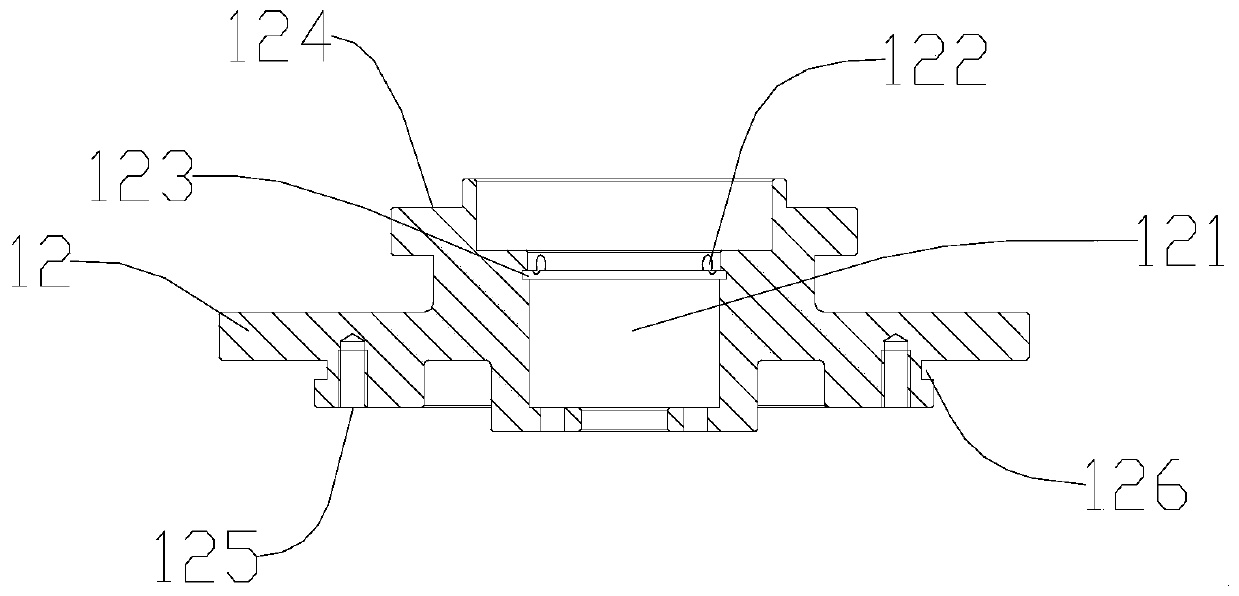

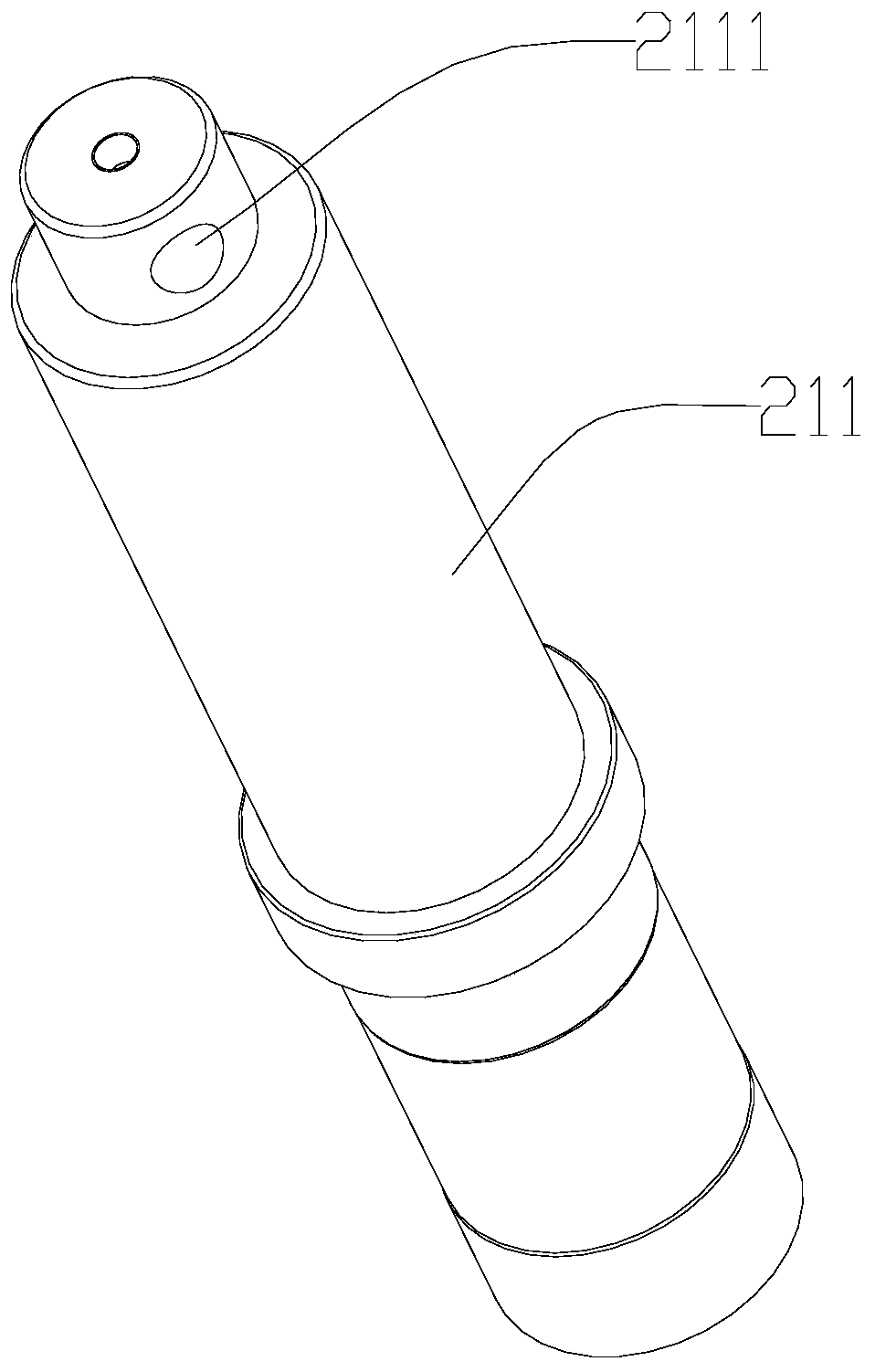

[0025] Such as Figures 1 to 5 A glue tank shown (where part of the glue feed channel is not shown, including the part of the back pressure valve and the pressure regulating valve), includes a glue tank and a glue feed channel for feeding glue into the cylinder body 1, wherein the cylinder body 1 includes The main body 11 and the cover body 12 are fixedly connected. The middle part of the cover body 12 is provided with an opening 121. The opening 121 is used for inserting the glue feeding channel into the main body 11 to feed glue. According to the cylinder body 1 The use environment requires long-term storage of glue, and for the corrosive ammonia water contained in the water-based glue, the cylinder body 1 needs to be made of a suitable corrosion-resistant material. It is preferable that the cylinder body 1 is made of ammonia-water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com