Phase change heat storage rubber, preparation method and application thereof

A phase-change heat storage and rubber technology, which is applied in chemical instruments and methods, heat exchange materials, hybrid/electric double-layer capacitor manufacturing, etc., can solve the difficulty of mixing and stirring molding, the performance decline of phase-change heat storage rubber, Affect heat storage performance and other issues, to achieve the effect of improving operability, large phase change enthalpy, and fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

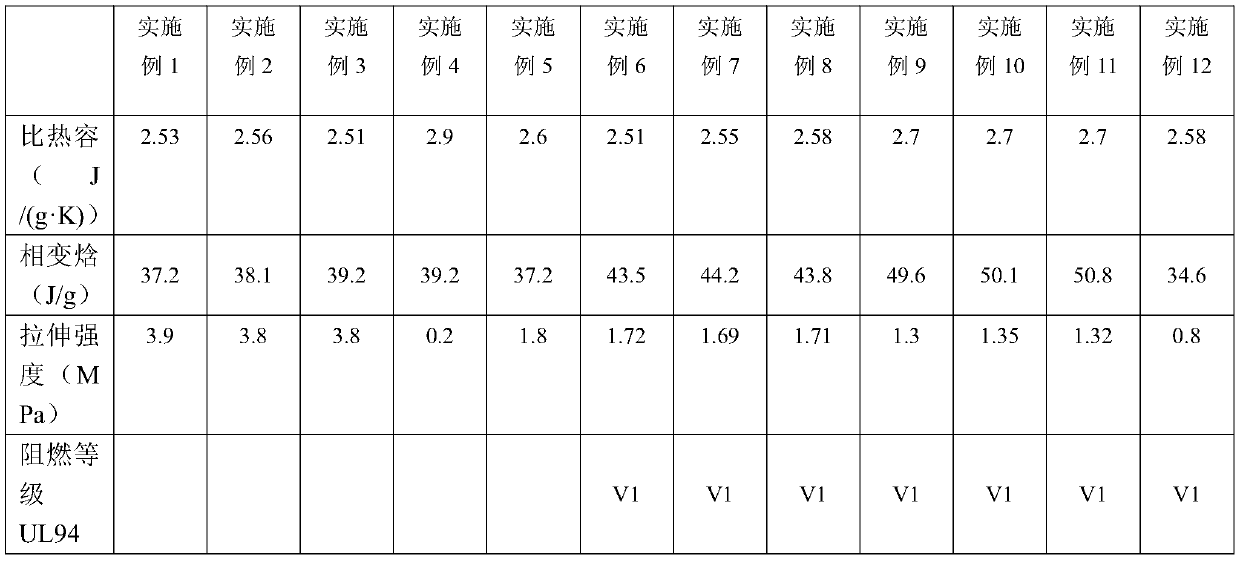

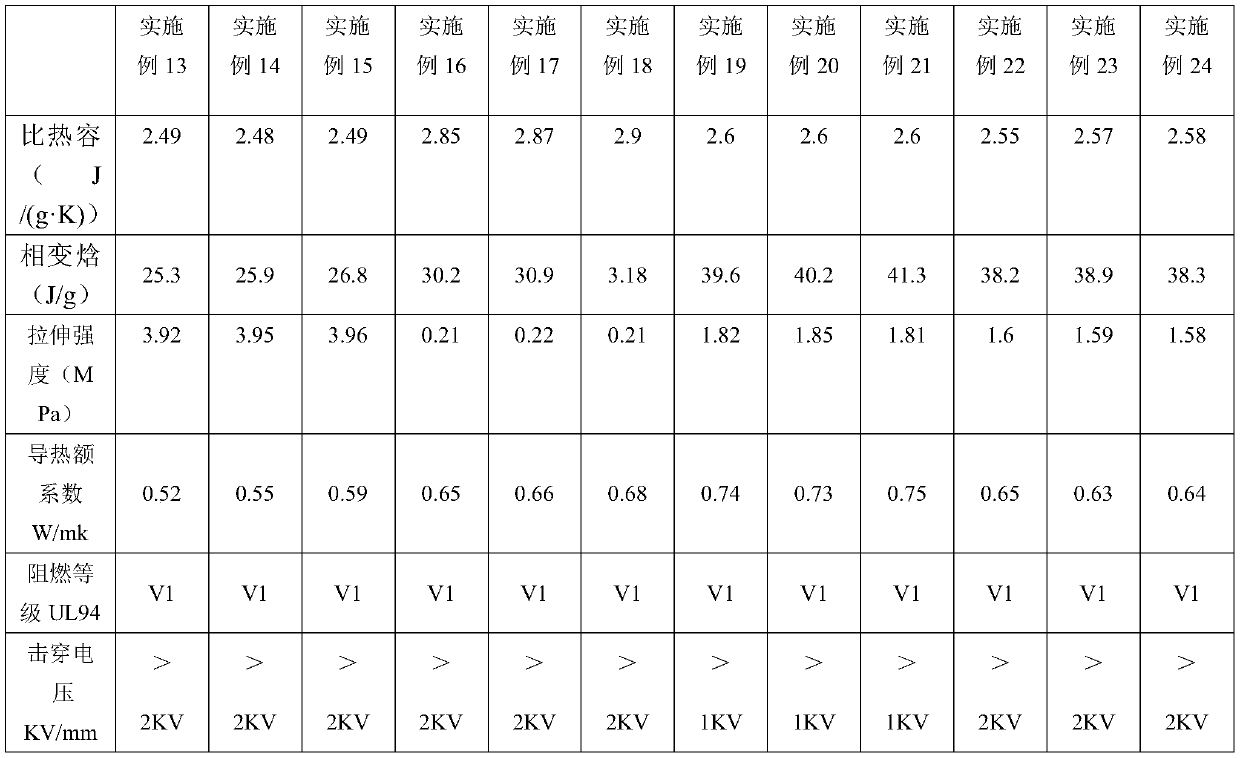

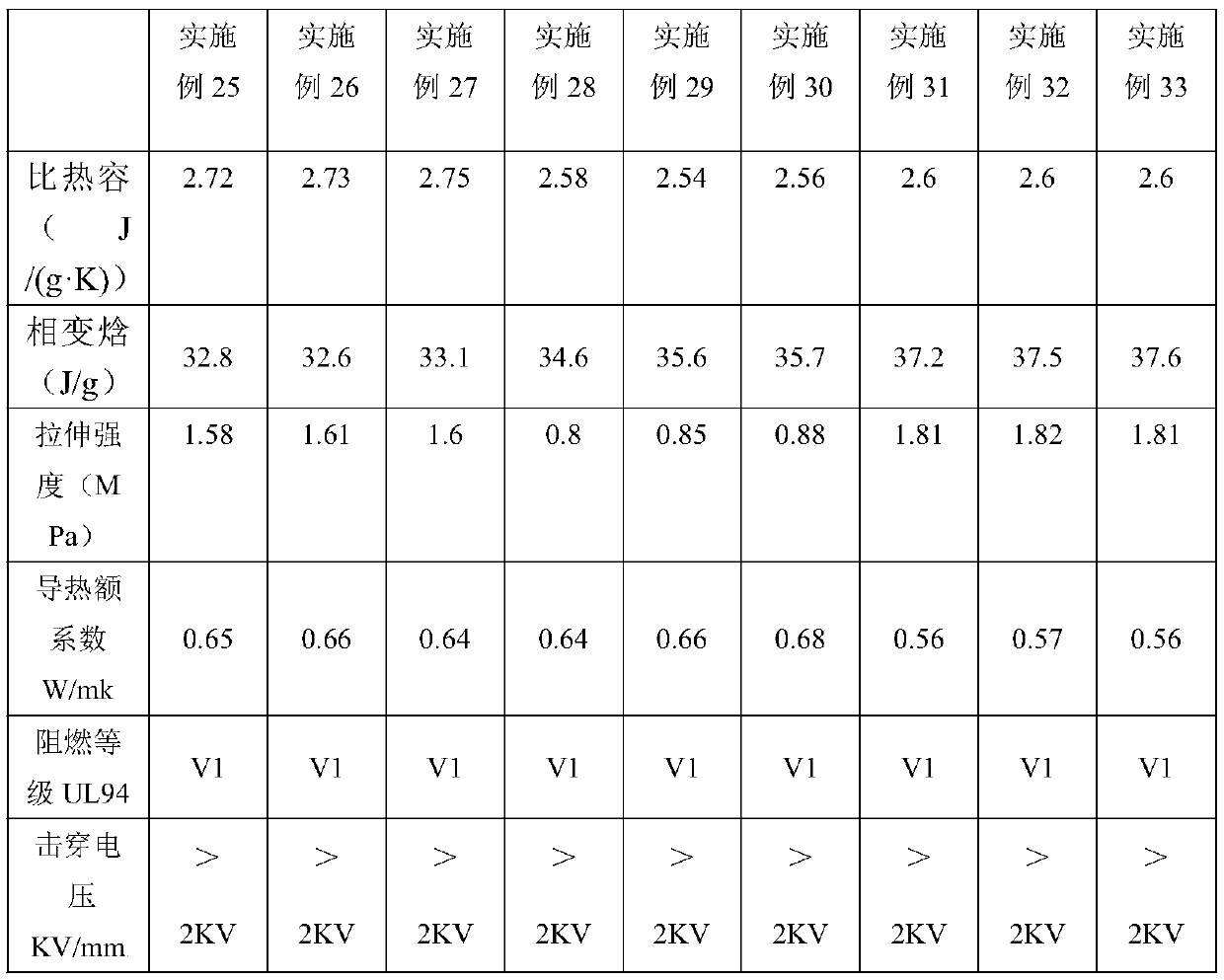

Examples

Embodiment 1

[0026] Phase change heat storage rubber, including the following components in parts by weight: 20 parts of NBR rubber and 10 parts of modified phase change powder;

[0027] The preparation method of the modified phase-change powder is as follows: heat and melt the paraffin, then add expanded graphite to the melted paraffin, the weight ratio of the added amount is 2% of the paraffin, and keep the mixed powder in a water bath or an oil bath for heat preservation. Then use a vibrating screen to vibrate for more than 4 hours, then use oil-absorbing paper to absorb oil, and then use a ball mill or a sand mill to grind the powder to obtain the modified phase-change powder.

Embodiment 2

[0029] Phase change heat storage rubber, including the following components by weight: 70 parts of NBR rubber and 10 parts of modified phase change powder;

[0030] The preparation method of the modified phase-change powder is as follows: heating and melting the 60 carbon atom alkane wax, and then adding nano-silica micropowder to the melted 60 carbon atom alkane wax, and the weight ratio of the added amount is 60 carbon atom alkane wax. 40%, after mixing, the powder is kept warm in a water bath or an oil bath, then vibrates with a vibrating screen for more than 4 hours, then absorbs oil with oil-absorbing paper, and then grinds the powder with a ball mill or a sand mill to obtain the modified phase-change powder .

Embodiment 3

[0032] Phase change heat storage rubber, including the following components in parts by weight: 40 parts of NBR rubber and 50 parts of modified phase change powder;

[0033] The preparation method of the modified phase-change powder is as follows: heating and melting the fatty acid, then adding hollow microsphere powder to the melted fatty acid, the weight ratio of the added amount is 20% of the fatty acid, and mixing the powder in a water bath or an oil bath Keep warm in medium temperature, then vibrate with a vibrating screen for more than 4 hours, then absorb oil with oil-absorbing paper, and then grind the powder with a ball mill or a sand mill to obtain the modified phase-change powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com