Patents

Literature

37results about How to "Stable heat storage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

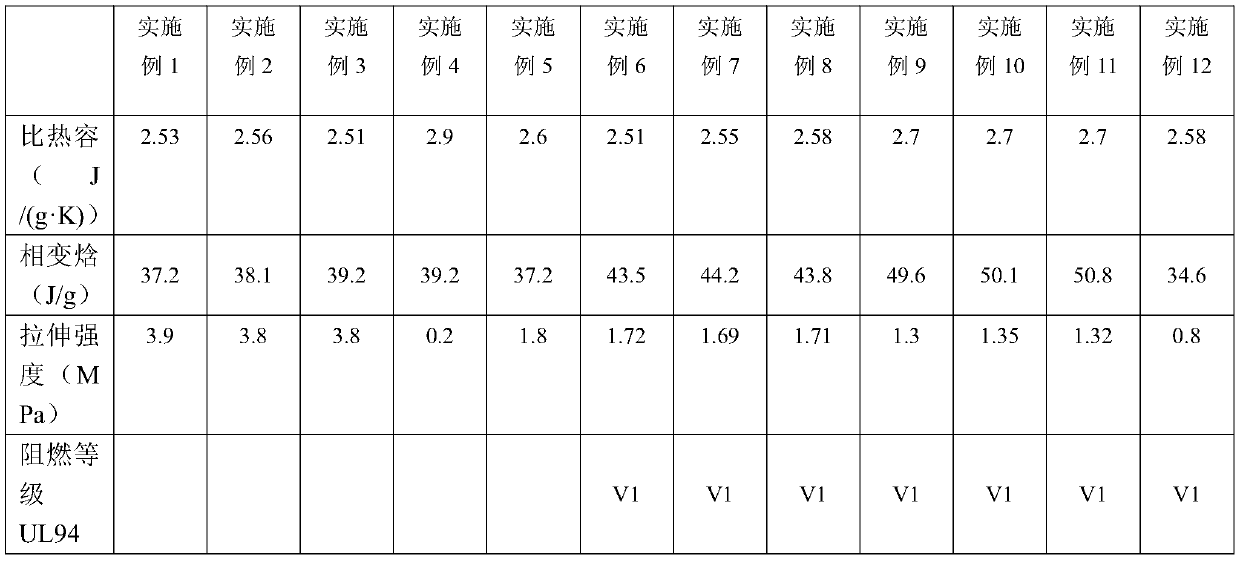

Pymetrozine-containing suspension agent composition

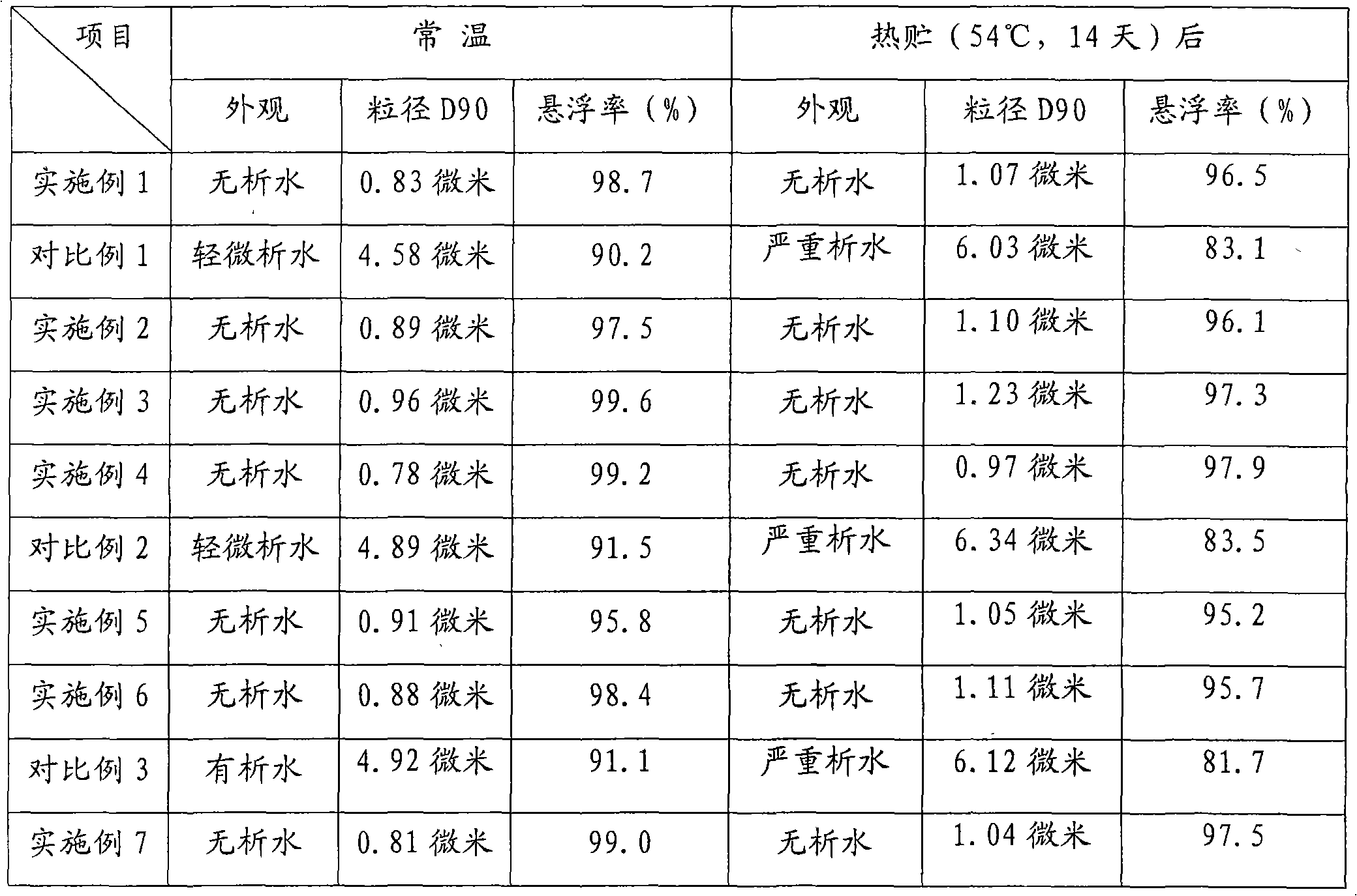

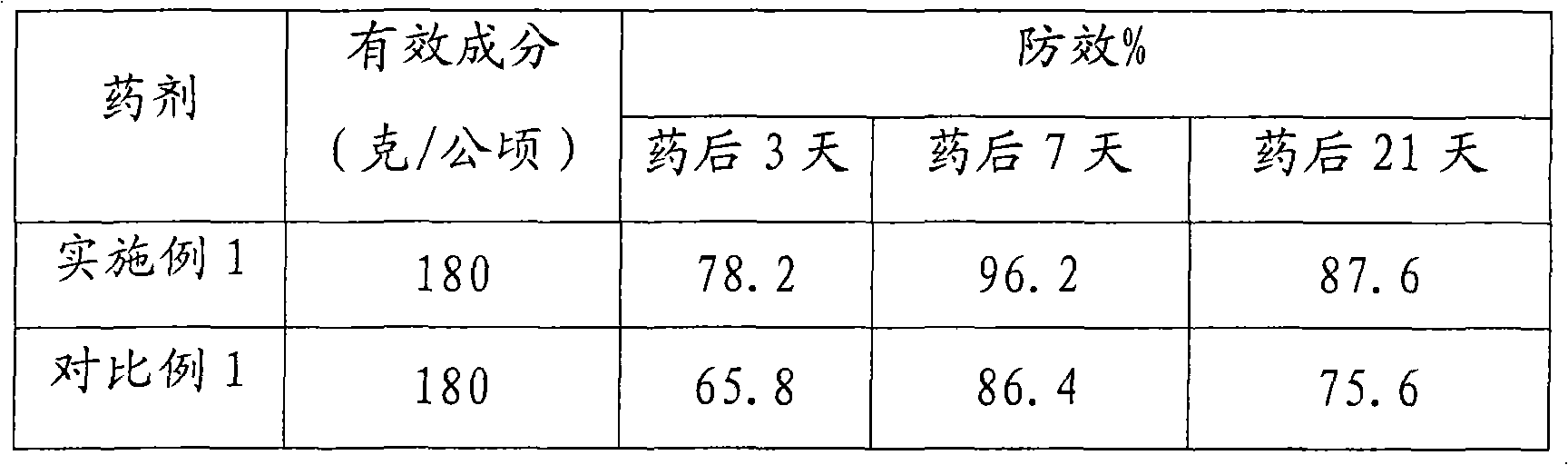

InactiveCN101669466ALarge particle sizeHigh suspension rateBiocideAnimal repellantsAdditive ingredientSuspending Agents

The invention discloses a pymetrozine-containing suspension agent composition which comprises pymetrozine and an effective ingredient B, wherein the effective ingredient B is any one of isoprocarb, nitenpyram, imidacloprid, avermectin, buprofezin, thiacloprid and acetamiprid. The composition consists of pesticide active ingredient, a wetting agent, a dispersing agent, an antifreeze agent, a defoaming agent, a thickening agent and water, wherein the dispersing agent is one or more of modified calcium lignosulphonate, alkyl naphthalene sulfonic acid condensate Morwet D-425, polycarboxylate Tersperse 2500, sodium poly (naphthaleneformaldehyde) sulfonate and sodium methylene bis-naphthalene sulfonate. The composition has the advantages of thinner particle size, higher suspension rate, better dispersibility, more stable heat storage property, better effect and the like.

Owner:SHENZHEN NOPOSION AGROCHEM

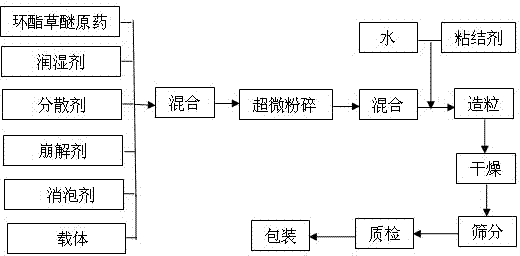

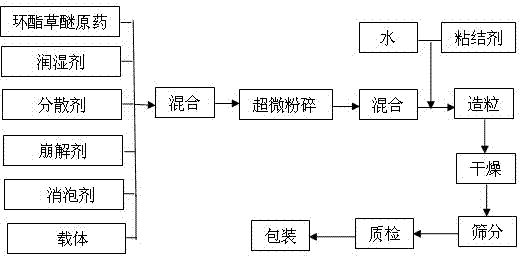

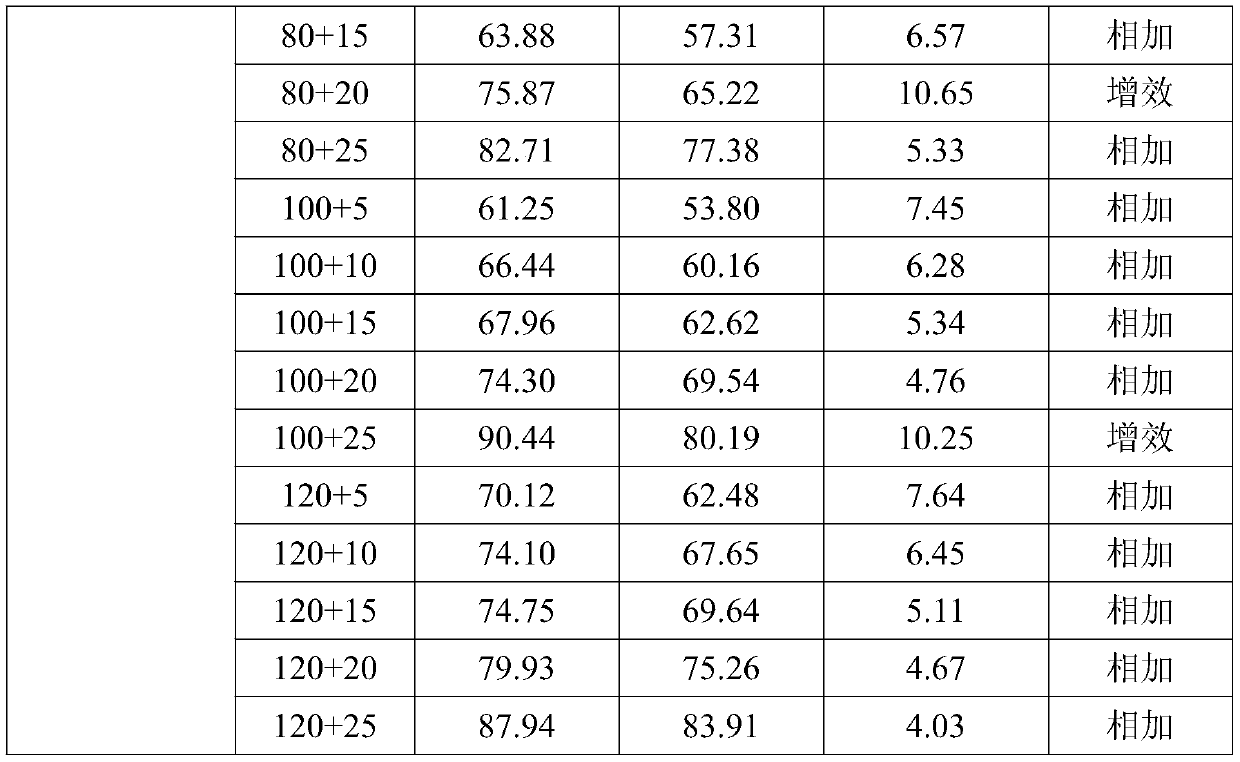

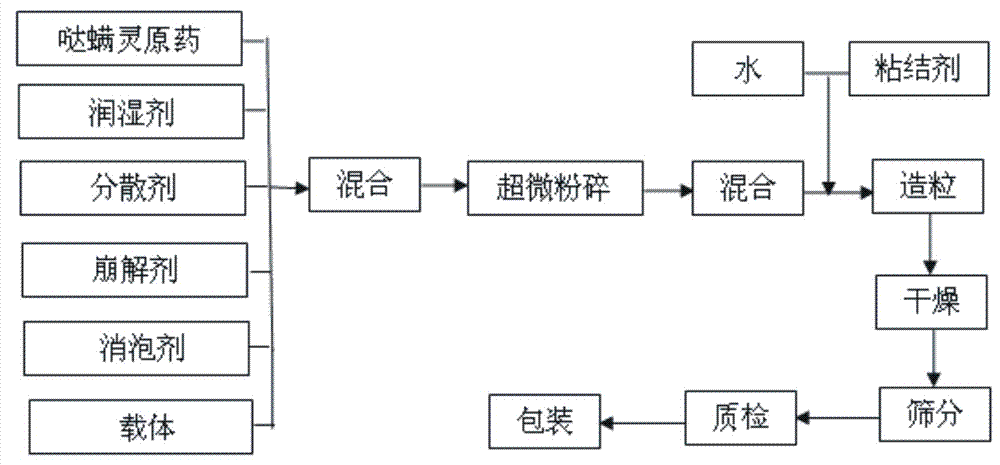

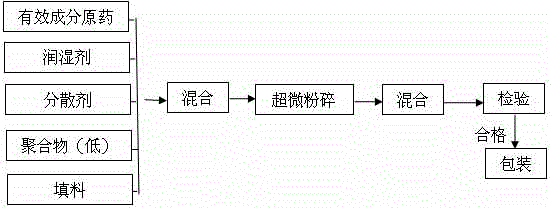

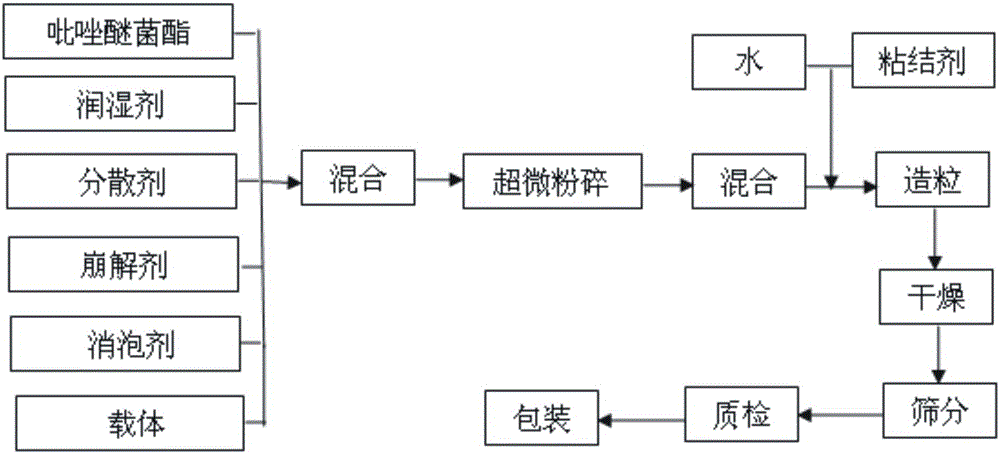

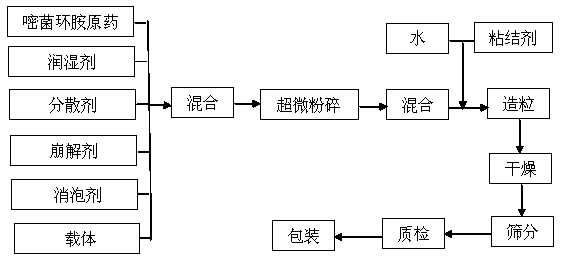

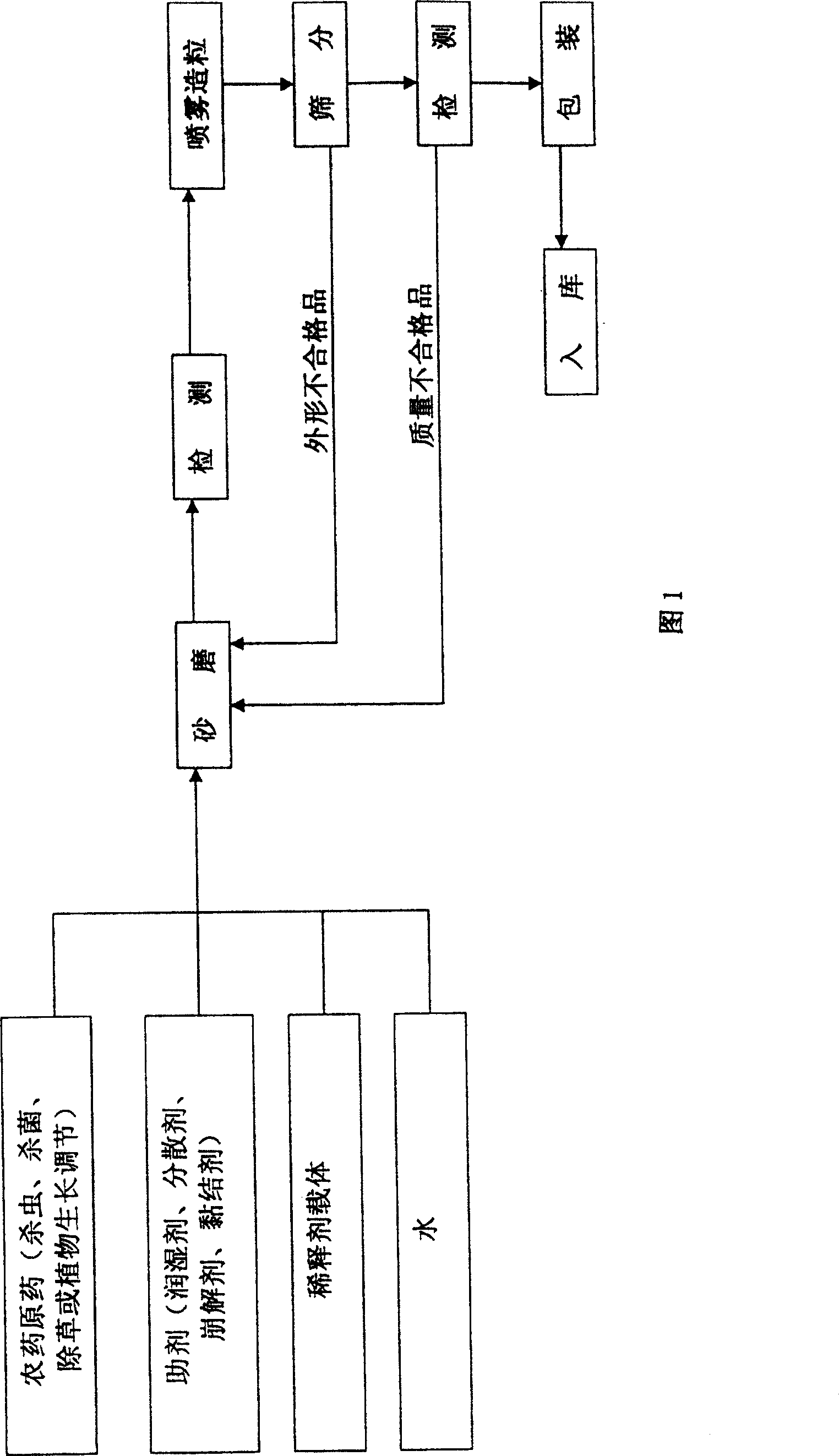

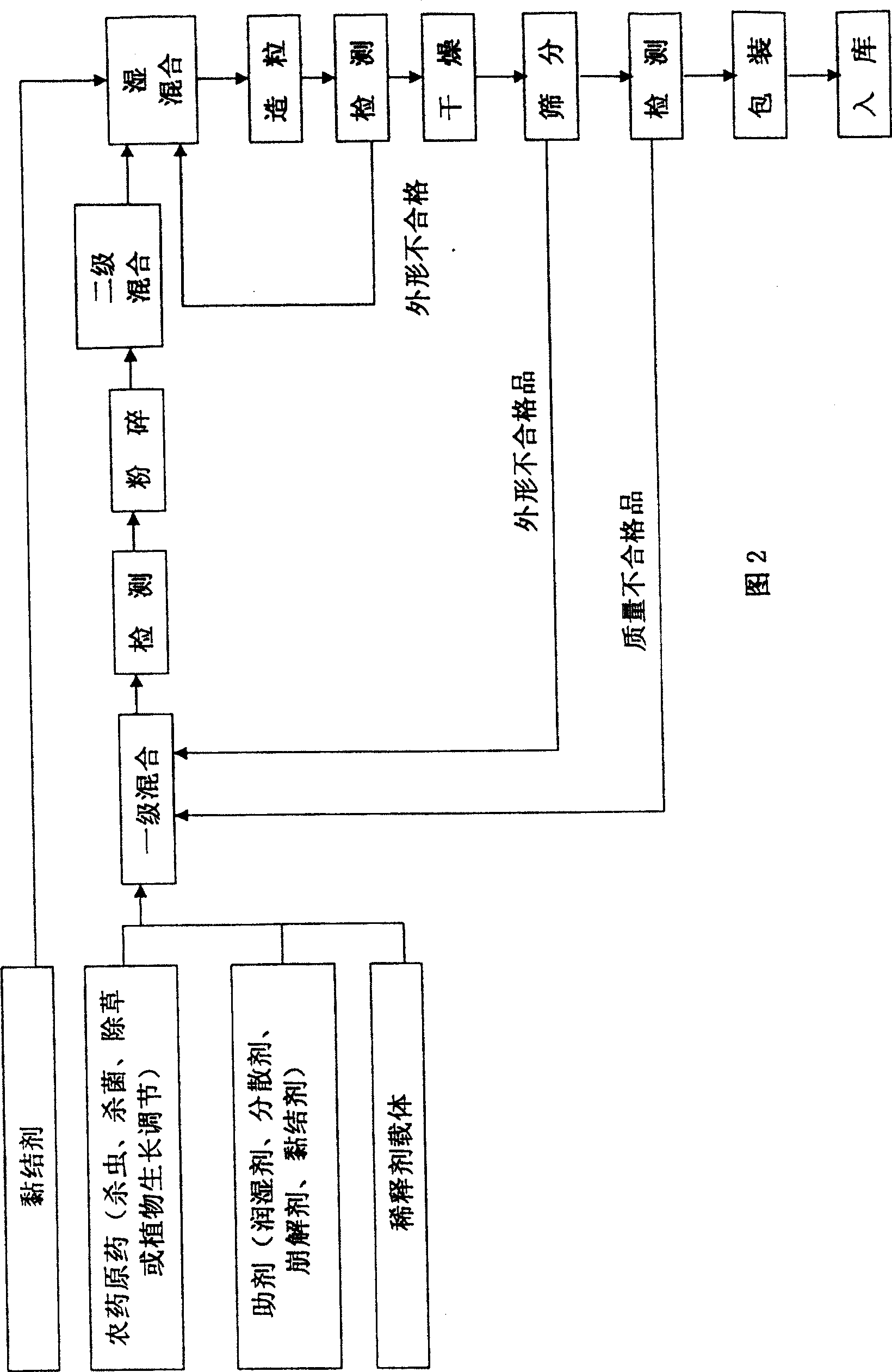

Pyriftalid water dispersible granule and preparation method thereof

InactiveCN102405902AImprove performanceEasy to packBiocideAnimal repellantsSuspending AgentsAqueous solution

The invention relates to a pyriftalid water dispersible granule and a preparation method thereof. The pyriftalid water dispersible granule is prepared from the following components in percentage by weight: 10-80% of pyriftalid, 1-8% of a wetting agent, 1-10% of a dispersing agent, 1-40% of a disintegrating agent, 0.3-5% of a defoamer, 0.5-4% of an adhesion agent, and the balance is a carrier; the preparation method comprises the following steps: uniformly mixing the raw materials except the adhesion agent; adding the mixture after ultrafine grinding to a water solution of the adhesion agent so as to carry out granulation; and finally, drying, screening, analyzing, testing, and putting in a storage. The pyriftalid water dispersible granule provided by the invention has the advantages of overcoming defects of a suspending agent and wettable powder, and having environmental friendliness and low use cost; and in processing and use processes, environmental pollution use cost of farmers are reduced.

Owner:GUANGDONG ZHONGXUN AGRI TECH

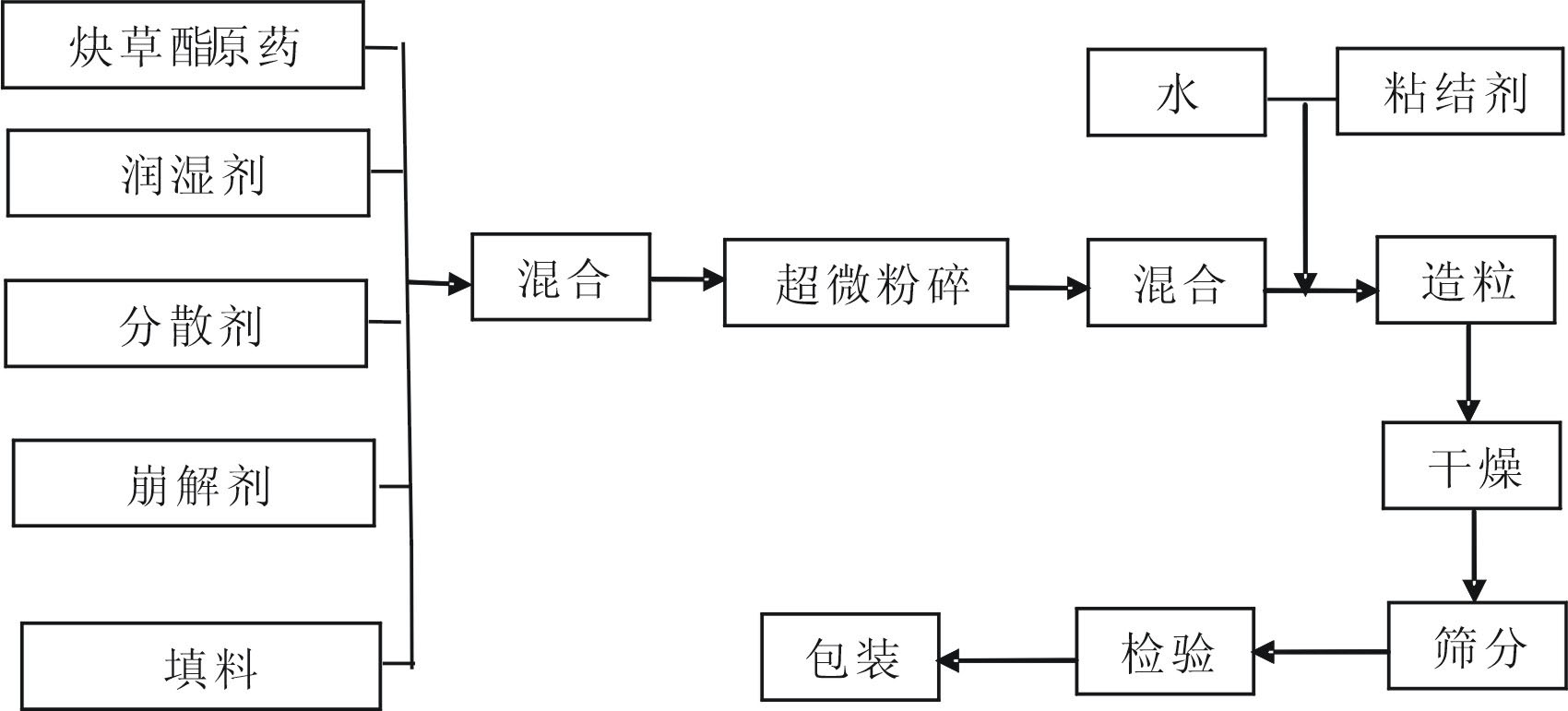

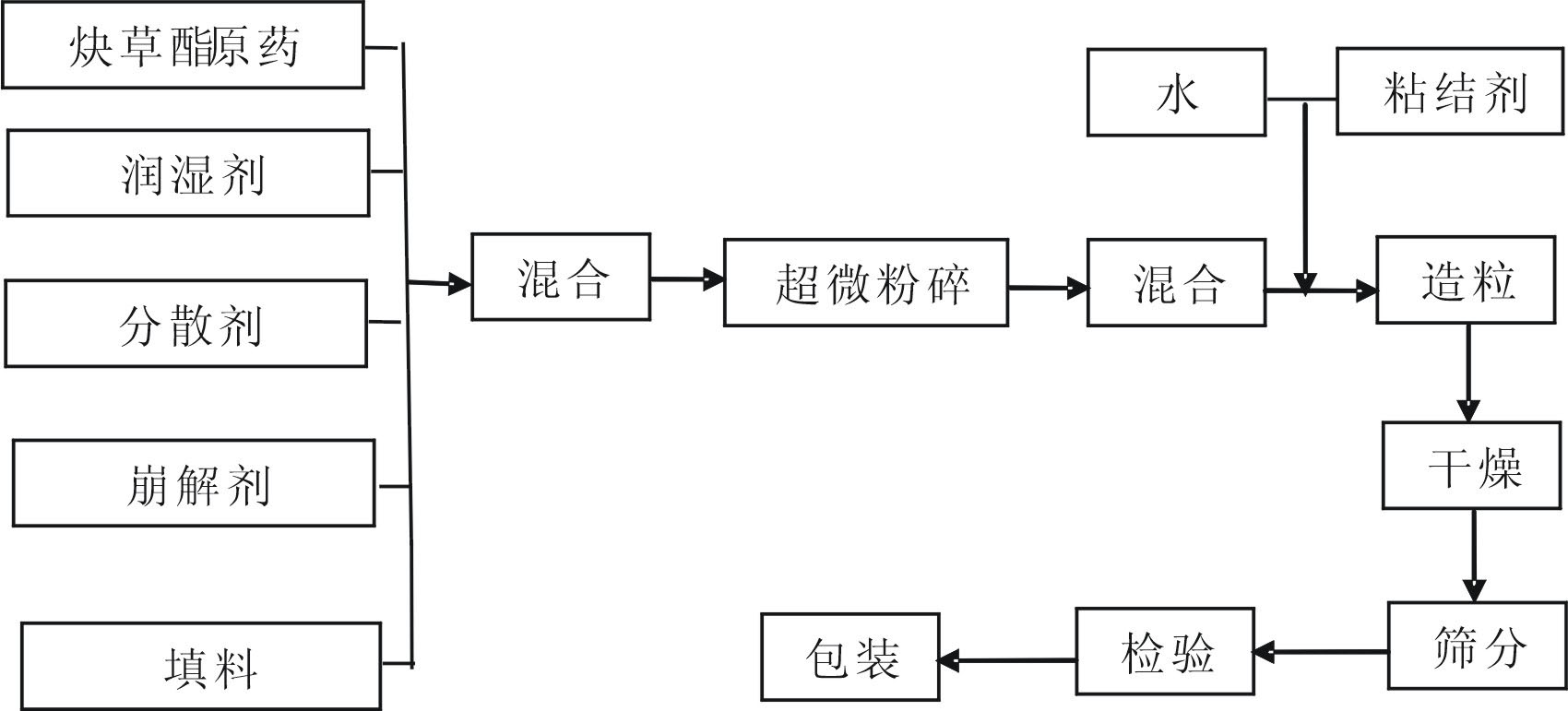

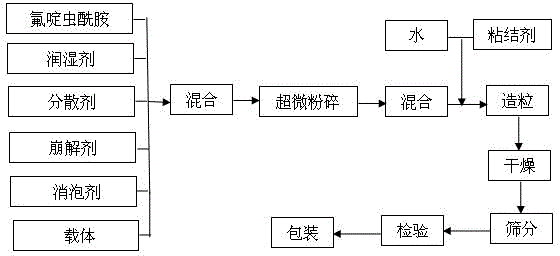

Clodinafop-propargyl water dispersible granule and preparation method thereof

InactiveCN102428921ASave resourcesReduce pollutionBiocideAnimal repellantsSuspending AgentsEnvironmental engineering

The invention relates to a clodinafop-propargyl water dispersible granule and a preparation method thereof. The clodinafop-propargyl water dispersible granule comprises the following components in percentage by weight: 5-85% of clodinafop-propargyl, 1-8% of wetting agent, 1-10% of dispersing agent, 1-10% of disintegrating agent, 0.5-4% of binding agent and the balance of packing material. The preparation method comprises the following steps of: uniformly mixing the above raw materials except for the binding agent; then, ultrafine grinding the mixture, and adding the powder into the water solution of binding agent to granulate; and finally drying, screening, analyzing, inspecting and warehousing the granule. The clodinafop-propargyl water dispersible granule overcomes the defects of suspension and wettable powder and combines the advantages of environmental protection and low use cost. The pollution to the environment is lowered during the processing and use process, and the use cost of peasants is lowered.

Owner:GUANGDONG ZHONGXUN AGRI TECH

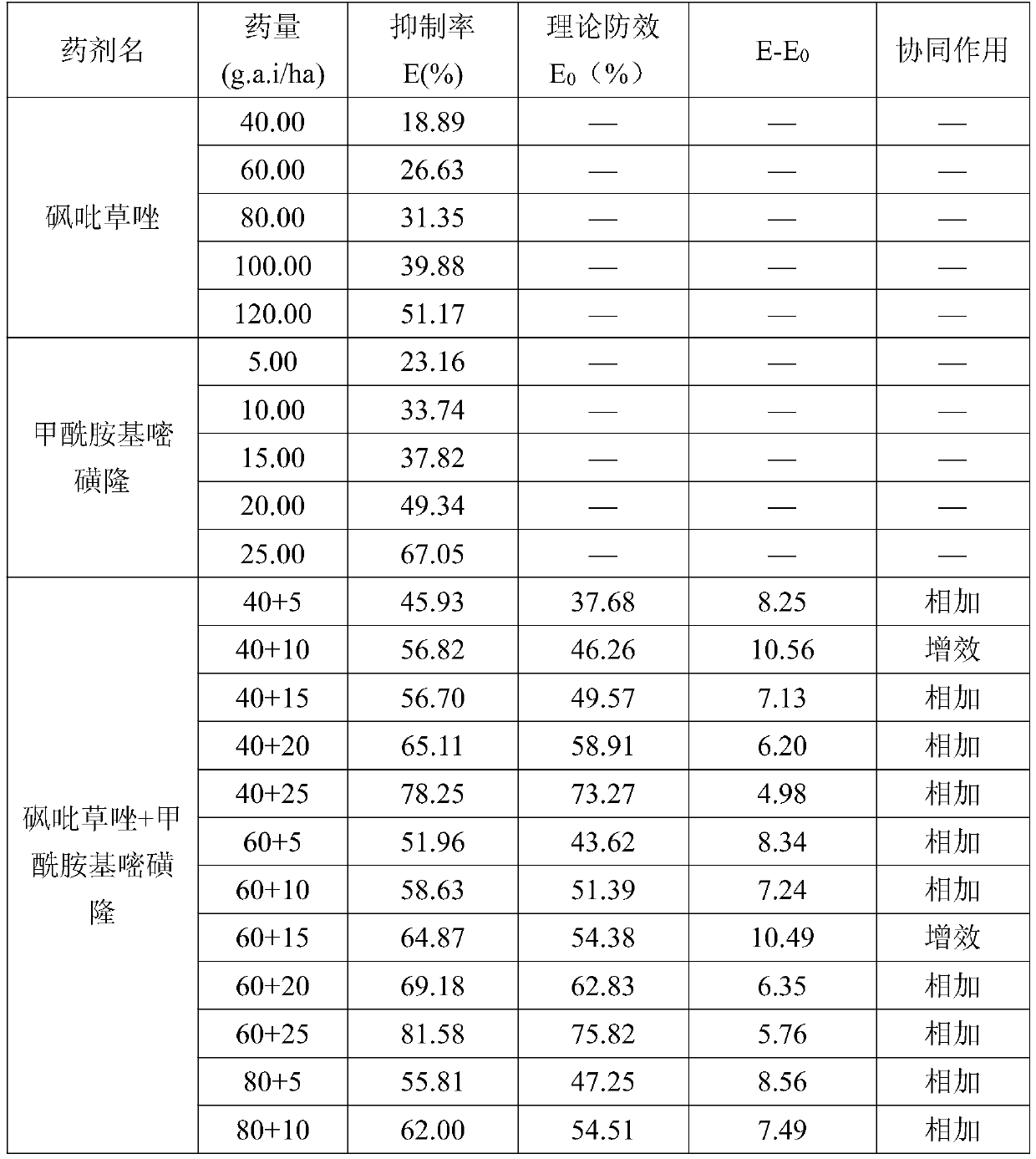

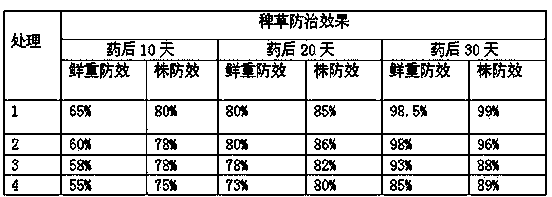

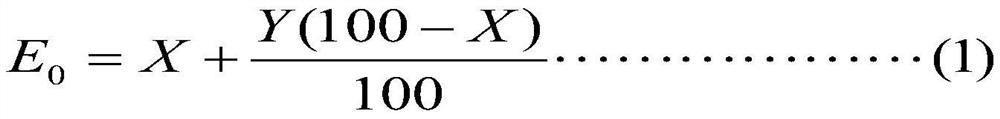

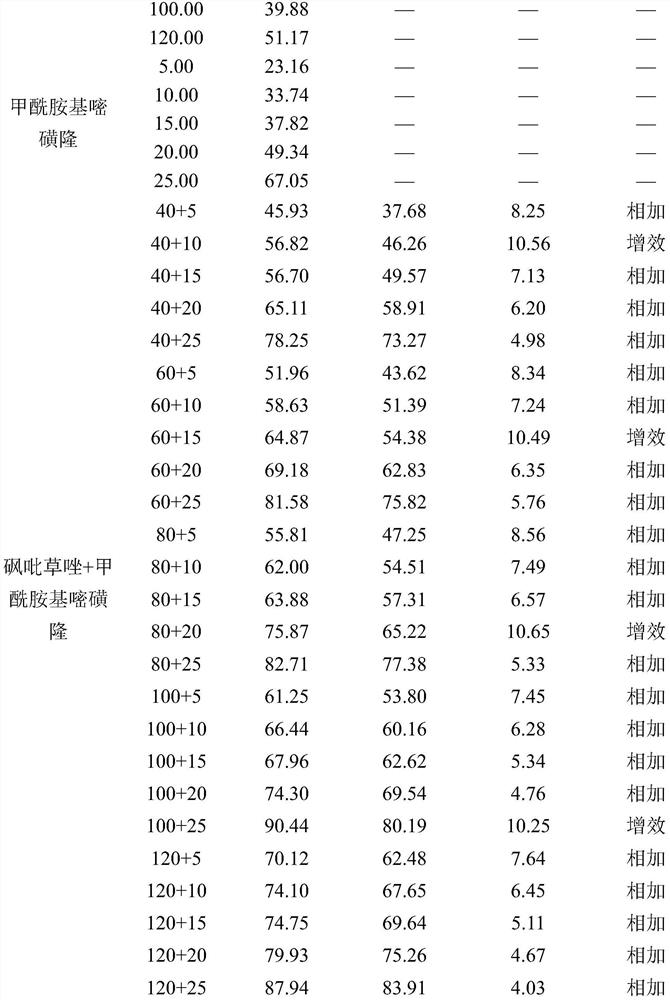

Herbicide composition containing pyrazole sulfone and formamido-pyrazosulfuron-ethyl

ActiveCN109730080AImprove weed control effectEasy to solveBiocideAnimal repellantsBristlegrassesGaleopsis bifida

The invention discloses a herbicide composition containing pyrazole sulfone and formamido-pyrazosulfuron-ethyl. The herbicide composition comprises effective components including, by weight, 1-80 parts of pyrazole sulfone and 1-50 parts of formamido-pyrazosulfuron-ethyl. The herbicide composition is used for controlling annual broadleaf weeds, grassy weeds and sedge weeds in sugarcane fields and mainly controlling common crabgrass herbs, barnyard grasses, green bristlegrass herbs, caper euphorbia seeds, goosegrass herbs, wild millets, nutgrasses, purslane herbs, Siberian cocklebur leaves, black nightshade herbs, bidens pilosa, tropic ageratum herbs, piemarkers, hairy datura and galeopsis bifida. The pyrazole sulfone and the formamido-pyrazosulfuron-ethyl are combined in use to enhance themedicinal effect of a herbicide, the weed control effect of the herbicide composition for the sugarcane fields is better than the activity of components individually used, and a weeding spectrum is widened. In addition, the herbicide composition is good in safety for sugarcanes and meets the safety requirements of pesticide preparations.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Insecticide composition as well as preparation method and application of insecticide composition

ActiveCN104222161AImprove stabilityImprove survival rateBiocideAnimal repellantsSporeActive component

The invention discloses an insecticide composition as well as a preparation method and application of the insecticide composition. The insecticide composition comprises active components, namely isaria fumosorosea and rotenone, wherein the mass percentage of isaria fumosorosea to rotenone in the insecticide composition is 2%-80%; and the mass ratio of isaria fumosorosea to rotenone is (0.1-70) to 1. The active components of the insecticide composition are compounded by adopting isaria fumosorosea and rotenone, so that the stability and validity period of the isaria fumosorosea are effectively increased, the spore survival rate is increased, the validity period is long, the insecticidal efficiency is high, the control efficiency reaches over 80%, and meanwhile, the insecticide composition is safe to environment, people and livestock, does not pollute the environment, and is beneficial to ecological balance.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI +1

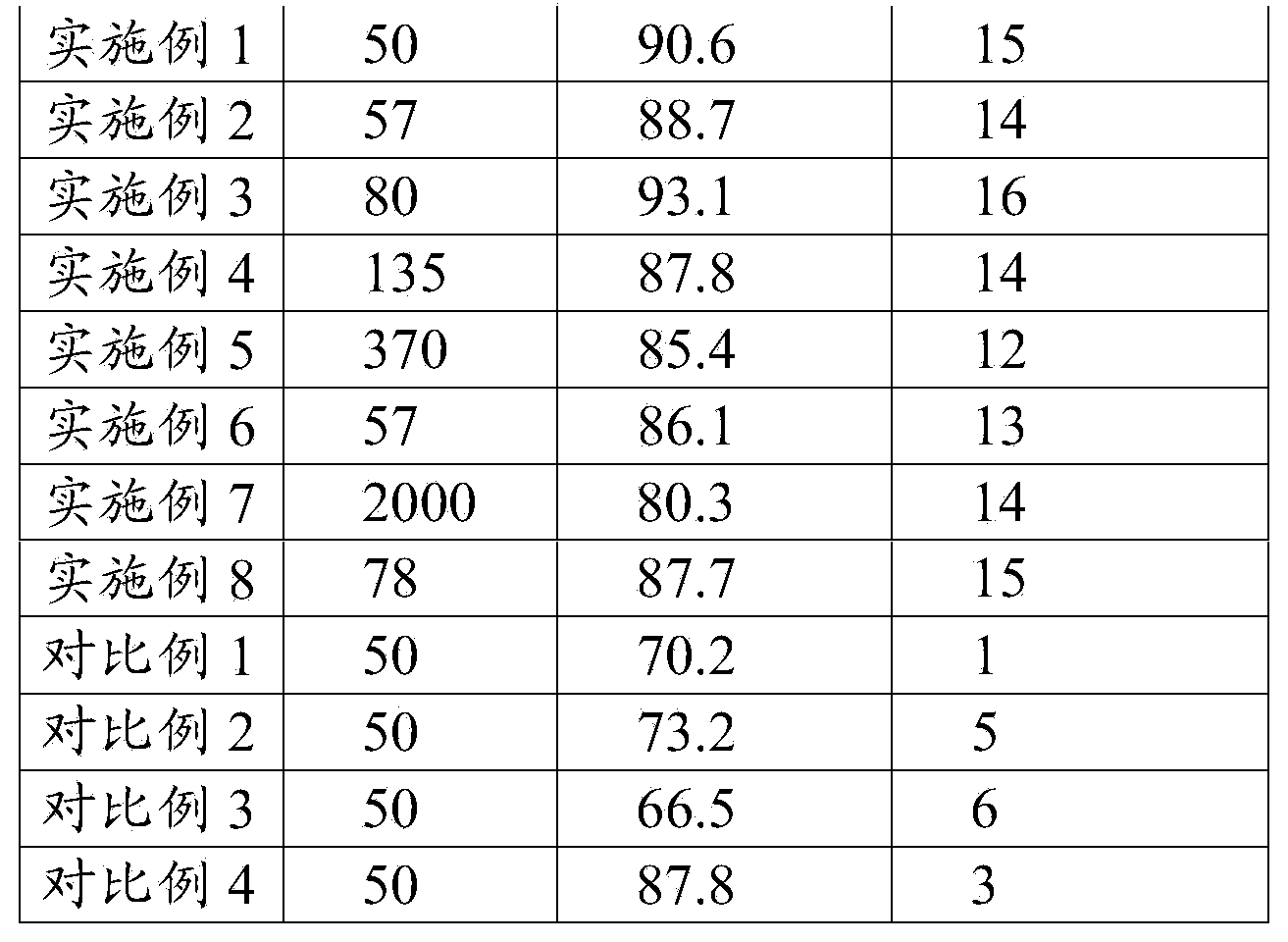

Pyridaben water dispersible granule and preparation method thereof

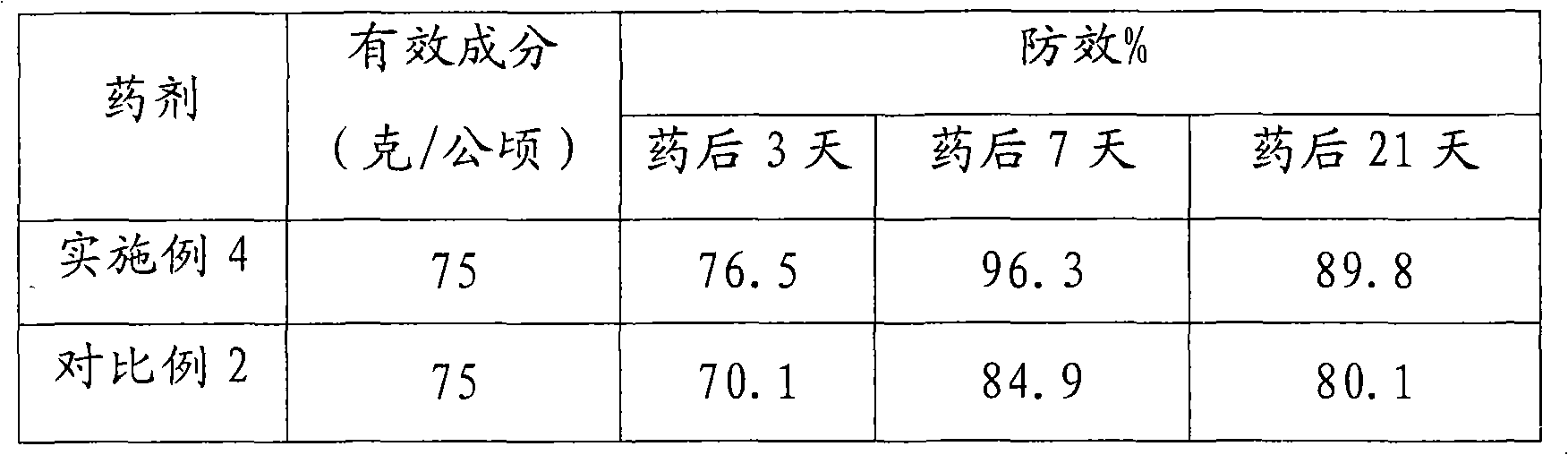

ActiveCN102726412ASave resourcesReduce pollutionBiocideAnimal repellantsSuspending AgentsDefoaming Agents

The invention discloses a pyridaben water dispersible granule and a preparation method thereof. The pyridaben water dispersible granulethe comprises components of, by weight, 10-80% of pyridaben, 1-8% of wetting agent, 1-10% of dispersing agent, 1-40% of disintegrating agent, 0.3-5% of defoaming agent, 0.5-4% of binder and the balance of carrier. The invention also discloses the preparation method of the water dispersible granule. The invention overcomes shortcomings of suspension and wettable powder, has both advantages of environmental protection and low cost, reduces environmental pollution during processing and usage, and also reduces usage cost for farmers. Therefore, the pyridaben water dispersible granule is a main trend in the development of pesticide formulations.

Owner:中高(天津)知识产权管理有限公司

Environment-friendly type wettable powder capable of being directly applied to rice field

InactiveCN103444707AReduce pollutionAvoid pollutionBiocideFungicidesPhysical chemistryEnvironmental engineering

The invention relates to an environment-friendly type wettable powder capable of being directly applied to a rice field. The environment-friendly type wettable powder comprises the components by weight percent: 0.1-90% of effective components, 1-5% of wetting agent, 1-10% of dispersing agent, 0.1-5% of diffusion agent, the balance of filler and water-soluble packaging film material. The auxiliary agents with different components and the diffusion agent are added into the wettable powder, and the wettable powder is packed in the water-soluble packaging material, so that the wettable powder has the advantages of being high in content of active components, low in environmental pollution, more uniform in spraying, more convenient in application, good in dispersing performance, stable in heat storage performance and the like; when being used, the environment-friendly type wettable powder is high in controlling efficiency and free from dust and liquid medicine drift when being applied, and enables people not to be contacted with the drug, thus being good in safety.

Owner:GUANGDONG ZHONGXUN AGRI TECH

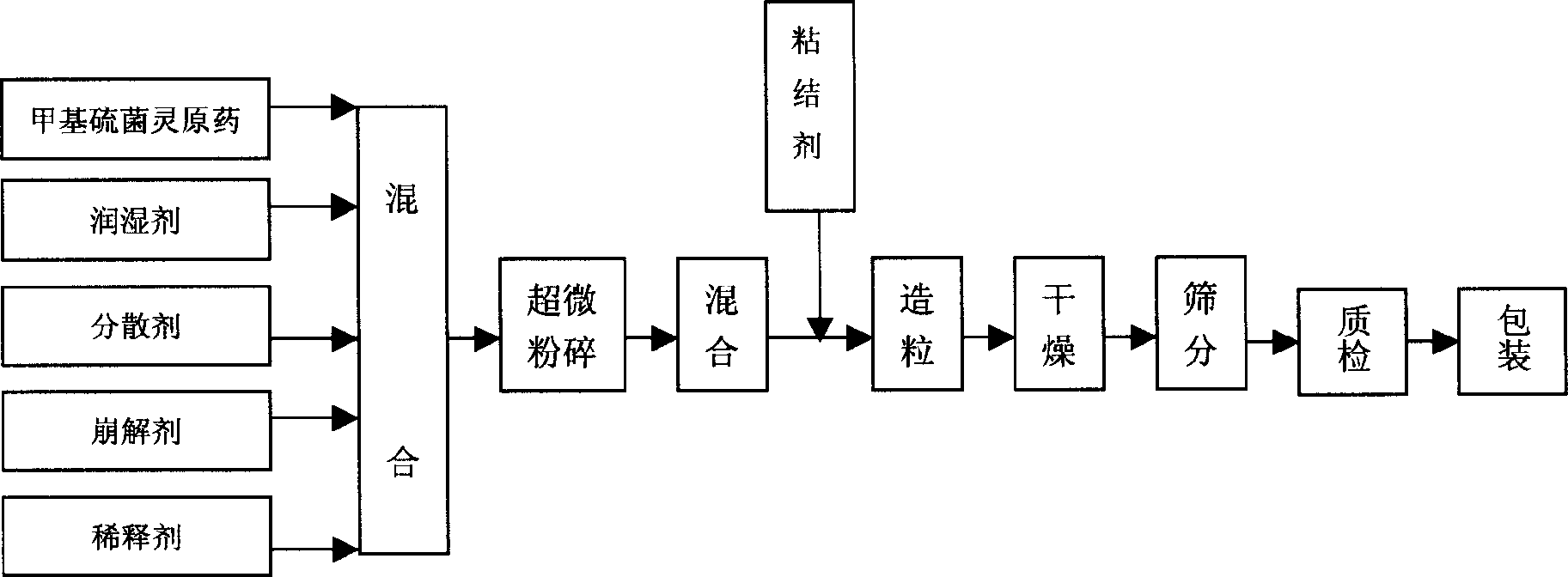

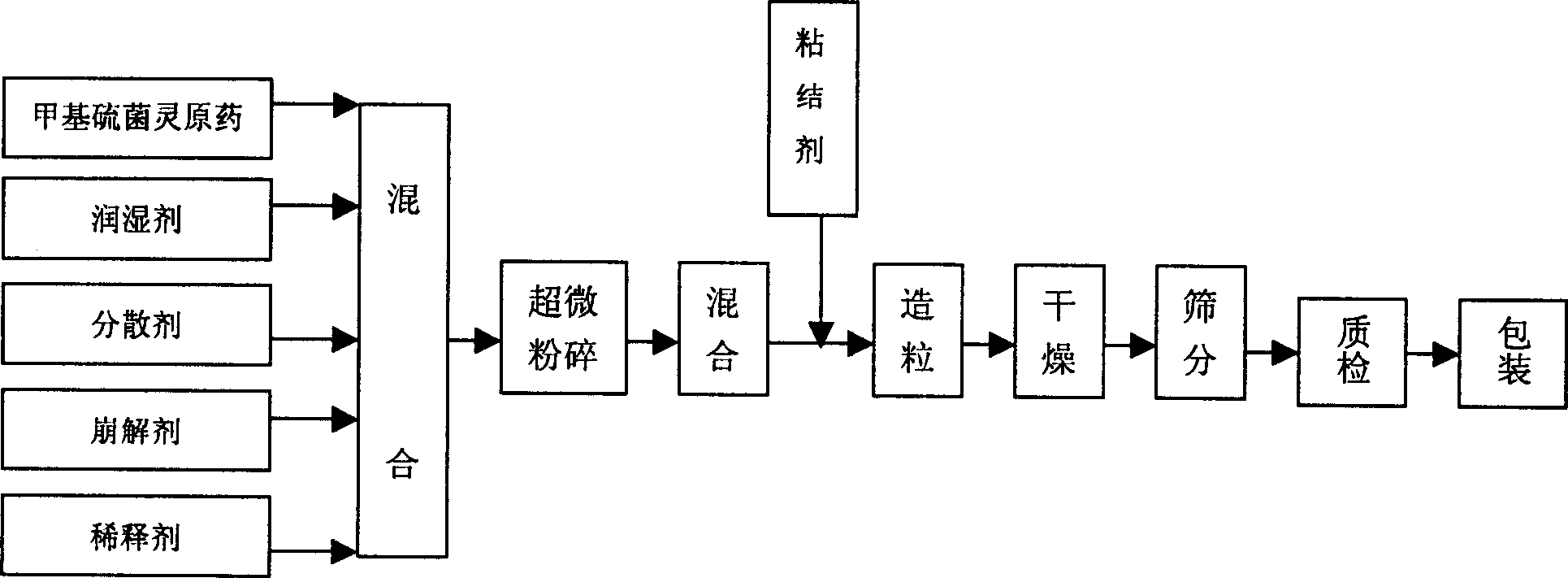

Thiophthanate methyl water dispersible granular agent and its formula

InactiveCN1596648AReduce pollutionHigh content of active ingredientsBiocideAnimal repellantsDispersityThiophanate-methyl

A granular thiophanate-methyl with high water dispersity is prepared from thiophanate-methyl powder, wetting agent, disperser, disintegrant, diluent and adhesive through proportional mixing, stirring, pulverizing, granulating, drying and sieving.

Owner:SHAANXI SUNGER ROAD BIO SCI

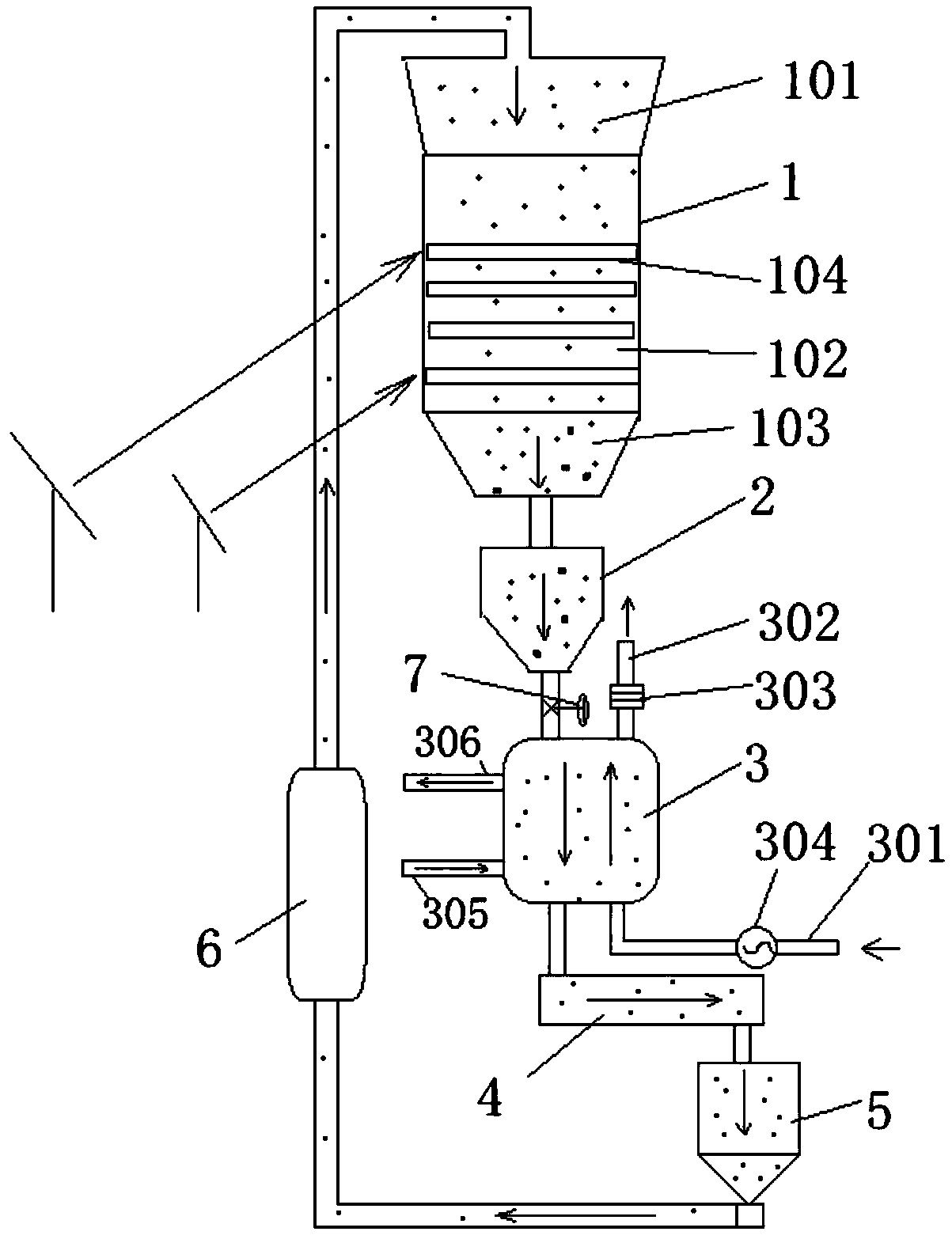

Solar heat storage system based on solid particles

PendingCN109682096AStable heat storage performanceAchieve high temperature heat transferSolar heating energyHeat storage plantsFluidized bedEngineering

The invention provides a solar heat storage system based on solid particles. The solar heat storage system comprises a suction tower assembly, a high-temperature particle stock bin, a fluidized bed heat exchange device and a low-temperature particle stock bin which are sequentially connected end to end to form a heat storage loop. According to the solar heat storage system, heat of solar beams areabsorbed through the solid particles and stored in the high-temperature particle stock bin and conducts heat exchange with a working medium through the fluidized bed heat exchange device, the workingmedium is heated to the high-temperature high-pressure state, and efficient heat storage and utilization of solar energy can be achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

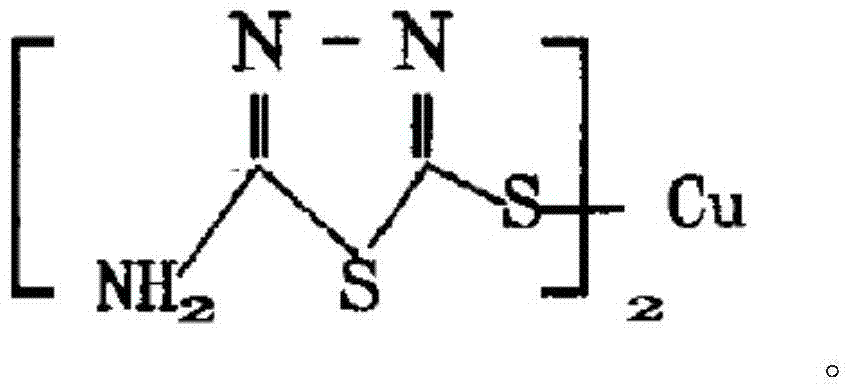

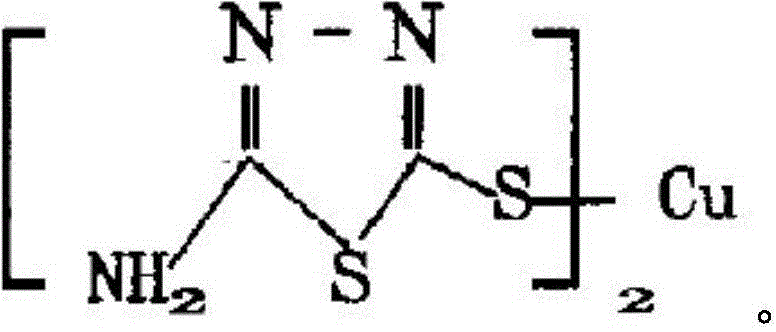

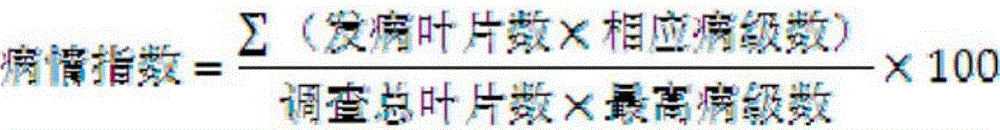

Tiger glue adipic acid copper water dispersion granula

InactiveCN101194608ANo large particlesImprove suspension stabilityBiocideFungicidesParticulatesBacterial disease

The invention discloses an agricultural bactericidal agent, namely, a copper dicarboxylate water particulate agent which is in a regular or irregular particle shape, wherein, the content of copper dicarboxylate (weight percentage) is 1%-80%, and the invention is characterized in that wetting agent, disintegrating agent, deflocculating agent and binding agent of certain proportions are filled in copper dicarboxylate raw material and mixed, mother dust is attained after being evenly churned and broken, negative ion water of certain proportion is filled in the mother dust and evenly mixed, particles are granulated, dried, and screened to attain the copper dicarboxylate water particulate agent. The agent overcomes the shortcoming of wettable power, which reduces the employing cost of farmers and pollution to the environment, has excellent dispersibility with high floating rate in water, and can improve preventing and curing effects, in particular to various bacterial diseases such as soft rot and canker of crops and the like.

Owner:张少武

Thiediazole copper water dispersible granule and preparation method thereof

ActiveCN104255716ASlow down production and developmentReduce pollutionBiocidePlant growth regulatorsFungicideBroad spectrum

The invention discloses a thiediazole copper water dispersible granule and a preparation method thereof. The thiediazole copper water dispersible granule comprises the following raw materials in parts by weight: 10-60 parts of thiediazole copper, 1-8 parts of a wetting agent, 1-8 parts of a dispersant, 1-30 parts of a disintegrating agent, 0.5-5 parts of a binding agent, 0.5-5 parts of a defoaming agent, 0.5-5 parts of a plant growth regulator, 0.5-3 parts of synergist and the balance of filler to 100 parts. The preparation method comprises the following steps: uniformly mixing the thiediazole copper with various auxiliary materials according to proportions, and grinding a mixture through a grinder to obtain mother powder; uniformly mixing the mother powder with a binding agent water solution, pelleting, forming and drying; and sieving dried granular materials, discharging materials after analyzing and inspecting to be qualified, packaging and storing. The thiediazole copper water dispersible granule disclosed by the invention, as an organic copper broad-spectrum fungicide, has a good effect on preventing and controlling various bacterial and fungal diseases; the thiediazole copper water dispersible granule is free from pollution and residue to crops, and the preparation disclosed by the invention has the advantages of good disintegration, high suspension rate and stable heat storage performance.

Owner:ZHEJIANG LONGWAN CHEM

Phosethy-Al and folpet water dispersible granule and preparation method thereof

The invention discloses a phosethy-Al and folpet water dispersible granule and a preparation method thereof. The effective components of the phosethy-Al and folpet water dispersible granule are phosethy-Al and folpet, and the water dispersible granule is prepared by mixing phosethy-Al and original folpet with wetting agents, dispersants, disintegrants, thinners and adhesives, wherein the content of the phosethy-Al is 20 to 60 percentage by weight, and the content of the folpet is 10 to 50 percentage by weight. The preparation method comprises the following steps of: stirring the components well and grinding the mixture to obtain original powder, adding a certain proportion of deionized water to the original powder and uniformly mixing, and then granulating, drying and sieving to obtain the phosethy-Al and folpet water dispersible granule. When the phosethy-Al and folpet water dispersible granule is used, the cost is lowered, and environmental pollution is reduced. Compared with the single dose, because the compound technique is adopted, the efficacy is improved, and the toxicity is lowered. Because different addition agents are added, the water dispersible granule has the advantages of high active component content, high disintegration speed, good dispersive property, good heat storage performance, high bactericidal potence, high safety, and the like.

Owner:LIMIN CHEM CO LTD

Hymexazol soluble granule and preparation method thereof

The present invention relates to a hymexazol soluble granule and a preparation method thereof. The hymexazol soluble granule includes the components by weight: 10-80% of hymexazol, 1-4% of a wetting agent, 1-4% of a dispersing agent, 0.3-5% of a defoaming agent, 0.5-4% of binder, 1-2% of a stabilizer and the balance a carrier. The invention also discloses a preparation method of the hymexazol soluble granule. The hymexazol soluble granule does not contain toxic and flammable aromatic hydrocarbon solvents, thereby preventing flammable and explosive phenomena in production and storage processes. The hymexazol soluble granule has no unpleasant odor and noxious gas, has small irritation to eyes, reduces pollution to environment, and greatly improves security for production, storage and users.

Owner:桐乡市恒达经编股份有限公司

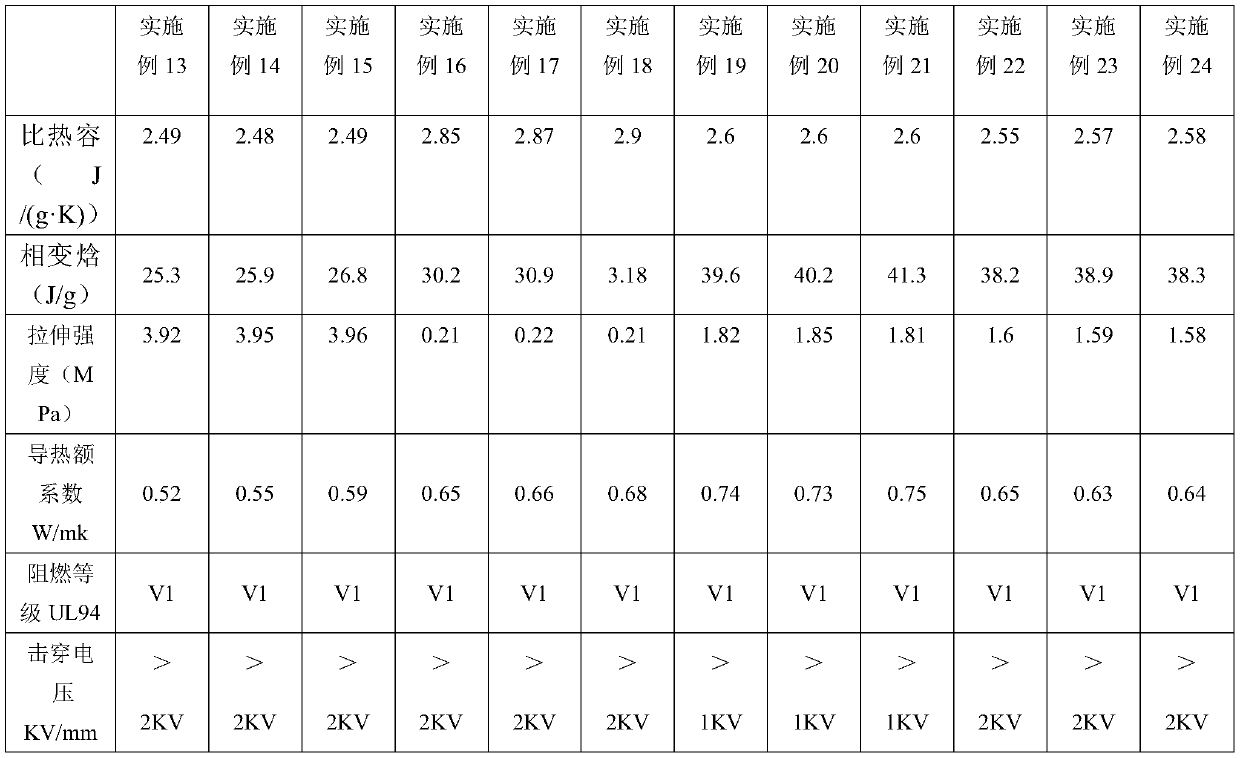

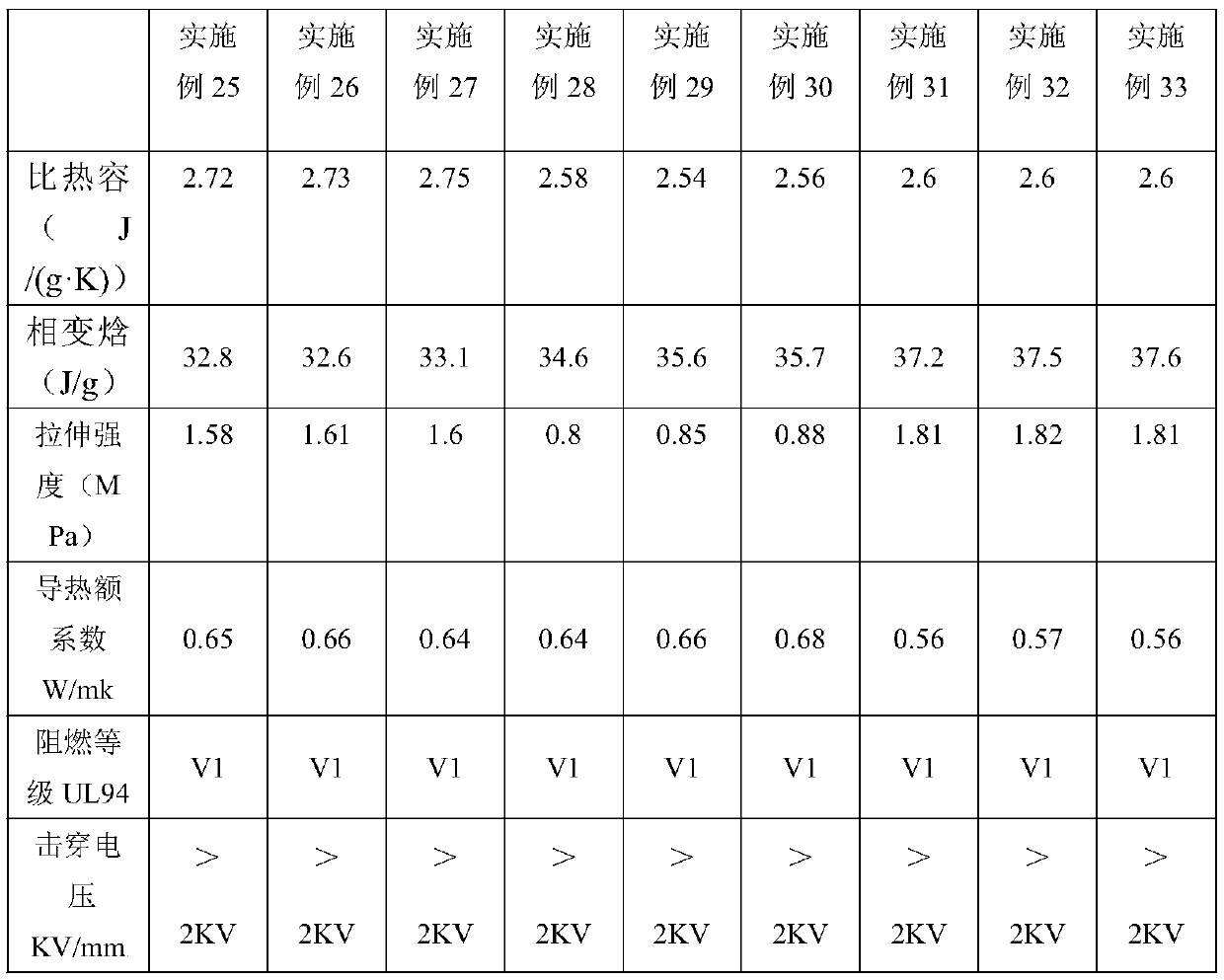

Phase change heat storage rubber, preparation method and application thereof

PendingCN110256741ARapid coolingSolve the technical problems of heatingProtecting/adjusting hybrid/EDL capacitorMultiple hybrid/EDL capacitorsCapacitancePhase change enthalpy

Owner:张立强

Polymer-containing wettable powder

InactiveCN103329894AReduce pollutionHigh content of active ingredientsBiocideAnimal repellantsChlorothalonilMaterials science

The invention relates to a polymer-containing wettable powder. The wettable powder is composed of, by weight, 0.1%-90% of effective constituent chlorothalonil or pymetrozine, 1%-5% of wetting agents, 1%-10% of dispersants, 0.1%-5% of polymers, 0.1%-10% of photosynthetic promoters, the balance being fillers. The wettable powder overcomes the defects of low suspension rate and no yield increase effect of ordinary high-content wettable powder. The wettable powder can reduce the pollution to the environment, reduce the packaging and transportation cost, raise the cost performance of products, and reduce the usage cost of farmers.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Thiophthanate methyl water dispersible granula

InactiveCN1278609CReduce pollutionHigh content of active ingredientsBiocideAnimal repellantsFungicideThiophanate-methyl

The invention discloses an agricultural fungicide, namely thiophanate-methyl water-dispersible granule. The thiophanate-methyl water-dispersible granule of the present invention is regular or irregular granule, and its component content is calculated by mass percentage: 40%-80% of thiophanate-methyl original powder, 2%-8% of wetting agent %, dispersant 3%-10%, disintegrant 3%-8%, diluent 5%-40%, binder 2%-10%. The above ingredients are mixed in proportion, stirred evenly, and the mother powder is obtained by crushing, and the mother powder and the binder are mixed evenly, then granulated, dried, and sieved to obtain the thiophanate-methyl water-dispersible granule. The granule overcomes the disadvantages of the suspension concentrate and the wettable powder, and reduces the use cost of farmers and the pollution to the environment during processing and use. Due to the addition of additives of different components, the invention has the advantages of high content of active components, fast disintegration speed, good dispersion performance and stable thermal storage performance, high bactericidal efficiency and good safety in use.

Owner:SHAANXI SUNGER ROAD BIO SCI

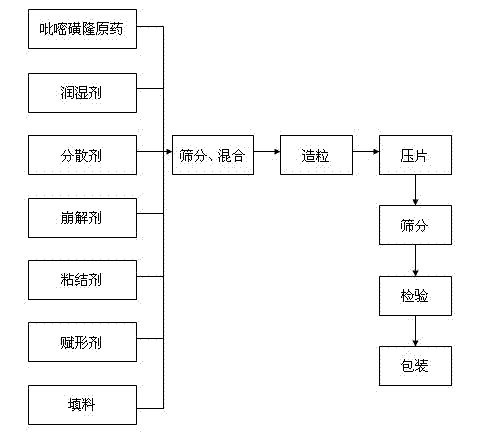

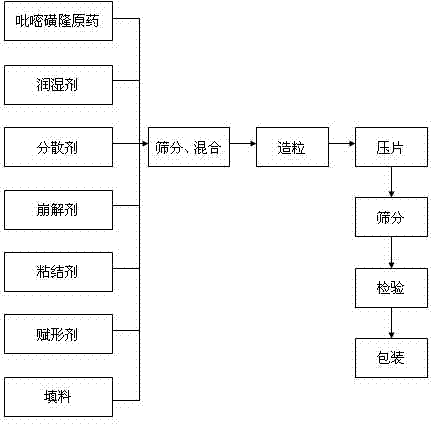

Pyrazosulfuron effervescent tablet and preparation method thereof

InactiveCN102524279ASave resourcesReduce pollutionBiocideAnimal repellantsEffervescent tabletDrug utilisation

The invention relates to a pyrazosulfuron effervescent tablet and a preparation method thereof, and the pyrazosulfuron effervescent tablet comprises the following components by weight: 0.5-20% of pyrazosulfuron, 1-5% of wetting agents, 5-10% of dispersants, 20-50% of disintegrating agents, 0.5-4% of binders, 5-40% of excipients, and the balance of fillers. The preparation method comprises the following steps: screening raw materials, well mixing to obtain a mixture; performing wet-method or dry-method granulation of the mixture; drying after the granulation is completed; tabletting and screening the granulated granules; performing analysis and examination to obtain the pyrazosulfuron effervescent tablet. The invention overcomes the disadvantages of suspending agents and wettable powder, and has the advantages of both environmental protection and low using cost; the invention reduces environment pollution, and reduces peasant labor intensity and environment pollution caused during drug administration.

Owner:GUANGDONG ZHONGXUN AGRI TECH

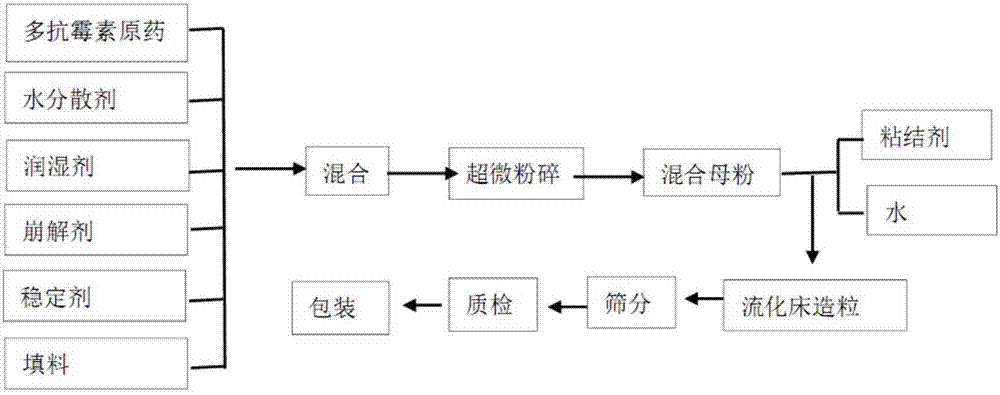

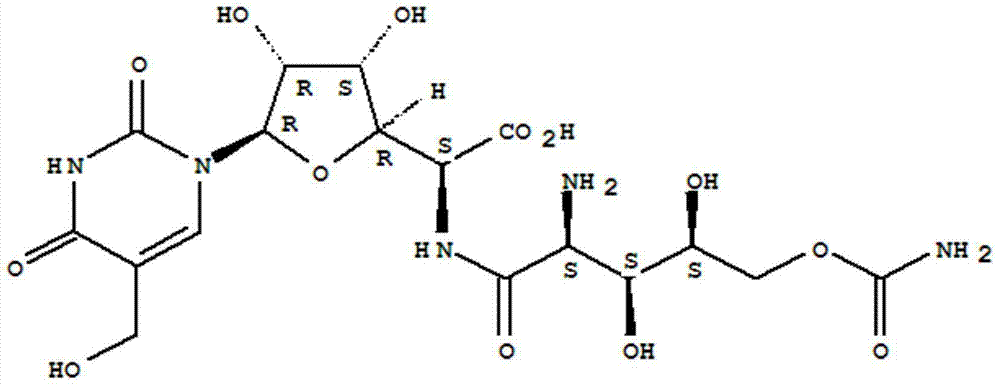

Polyoxin water-dispersible granule, its preparation method and application

ActiveCN103814891BMeet processing needsIncrease production capacityBiocideFungicidesWater dispersibleStabilizing Agents

The invention relates to a polyoxins water dispersible granule as well as a preparation method and application thereof, and aims to solve the technical problems that in the prior art the environment is polluted, the human body health is damaged, and the application cost is high. The polyoxins water dispersible granule provided by the invention comprises the following components in percentage by weight: 50-65% of polyoxins, 4-5% of wetting agent, 5-9% of water dispersing agent, 3-5% of disintegrating agent, 2-3% of binding agent, 0.4-1% of stabilizing agent and the balance of packing. The polyoxins water dispersible granule can be widely applied to the field of polyoxins water dispersible granule preparation.

Owner:RUSHAN HANWEI BIO TECHN & SCI

Electric-conduction ink for micro gravure printing, and preparation method thereof

InactiveCN110628270AImprove solubilityImprove performanceInksElectrical resistance and conductanceSolvent

The invention discloses electric-conduction ink for micro gravure printing, wherein the electric-conduction ink comprises, by mass, 5-10 wt% of protonic acid doped polyaniline, 20-30 wt% of a mixed resin, 50-55 wt% of a mixed solvent, 1.0-2.0 wt% of an auxiliary agent and 14-21 wt% of electric-conduction carbon black. The invention further discloses a preparation method of the ink, wherein the preparation method comprises: (1) preparing protonic acid doped polyaniline; (2) uniformly dispersing electric-conduction ink components; and (3) adding into a sand mill, and sanding to obtain the electric-conduction ink. According to the invention, the obtained electric-conduction ink can solve the problems of poor heat storage stability, non-uniform resistance distribution, low solvent selectivityand the like of the electric-conduction ink in the prior art, has characteristics of low viscosity and small fineness, and is suitable for micro gravure printing, wherein the printed product has characteristics of thin thickness, uniform and fine in appearance and excellent electrical conductivity, wherein the thickness of the printed layer is 2-30 [mu]m, and the horizontal resistance is smaller than 200 m[omega].

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

A kind of flonicamid water dispersible granule and preparation method thereof

ActiveCN102696589BImprove performanceEasy to packBiocideAnimal repellantsWater dispersibleDefoaming Agents

The invention discloses a flonicamid water dispersible granule and a method for preparing the flonicamid water dispersible granule. The flonicamid water dispersible granule comprises the following components in percent by weight: 10-80% of flonicamid, 1-8% of wetting agent, 1-10% of dispersing agent, 1-40% of disintegrating agnet, 0.5-4% of binding agent, 0.3-5% of defoaming agent and the balance of carrier. The flonicamid water dispersible granule overcomes the defects of the wettable powder and other traditional preparations, has the advantages of environment friendliness and low use cost and causes less pollution to the environment when being processed and used. Due to the adoption of the flonicamid water dispersible granule, the use cost of the peasants is reduced.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Pyraclostrobin water-dispersible granule and preparation method thereof

ActiveCN102726379BSave resourcesReduce pollutionBiocideFungicidesSuspending AgentsPesticide formulation

Owner:中高(天津)知识产权管理有限公司

Cyprodinil water dispersible granule and preparation method thereof

The invention discloses a cyprodinil water dispersible granule and a preparation method thereof; the granule comprises the following components by weight: 10-80% of cyprodinil, 1-8% of a wetting agent, 1-10% of a dispersant, 1-40% of a disintegrating agent, 0.5-4% of a binder, 0.3-5% of an antifoaming agent, and the balance of carriers. The invention also discloses the preparation method of the cyprodinil water dispersible granule. The invention overcomes the disadvantages of suspending agents and wettable powder, and combines the advantages of both environmental protection and low application cost; during processing and application, environment pollution is reduced, and the application cost for peasants is reduced.

Owner:JIANGXI ZHONGXUN AGROCHEM

Water dispersion granules agent of dithane

ActiveCN100551240CNo large particlesImprove suspension stabilityBiocideFungicidesDexamethasoneWater dispersible

The invention discloses an agricultural fungicide, namely zinc water dispersible granule. The zinc zinc water-dispersible granule of the present invention is in the form of regular or irregular granules, wherein the content of zinc zinc is (percentage by weight) 40%-80%. It is made by adding a certain proportion of wetting agent, dispersant, disintegrating agent, diluent and binder to the original drug of Zinc zinc, and mixing it evenly, and then crushing to obtain mother powder. The ionized water is evenly mixed, then granulated, dried, and sieved to obtain the zinc zinc water-dispersible granule. The granules overcome the disadvantages of wettable powders, and in the process of processing and use, reduce the use cost of farmers and the pollution to the environment. Due to the addition of additives with different components, the present invention has high content of active components and is easy to disintegrate. It has the advantages of fast speed, good dispersion performance and stable heat storage performance. It has high sterilization efficiency and good safety in use.

Owner:SHAANXI SUNGER ROAD BIO SCI

Pyridaben water-dispersible granule and preparation method thereof

ActiveCN102726412BSave resourcesReduce pollutionBiocideAnimal repellantsSuspending AgentsPesticide formulation

The invention discloses a pyridaben water dispersible granule and a preparation method thereof. The pyridaben water dispersible granulethe comprises components of, by weight, 10-80% of pyridaben, 1-8% of wetting agent, 1-10% of dispersing agent, 1-40% of disintegrating agent, 0.3-5% of defoaming agent, 0.5-4% of binder and the balance of carrier. The invention also discloses the preparation method of the water dispersible granule. The invention overcomes shortcomings of suspension and wettable powder, has both advantages of environmental protection and low cost, reduces environmental pollution during processing and usage, and also reduces usage cost for farmers. Therefore, the pyridaben water dispersible granule is a main trend in the development of pesticide formulations.

Owner:中高(天津)知识产权管理有限公司

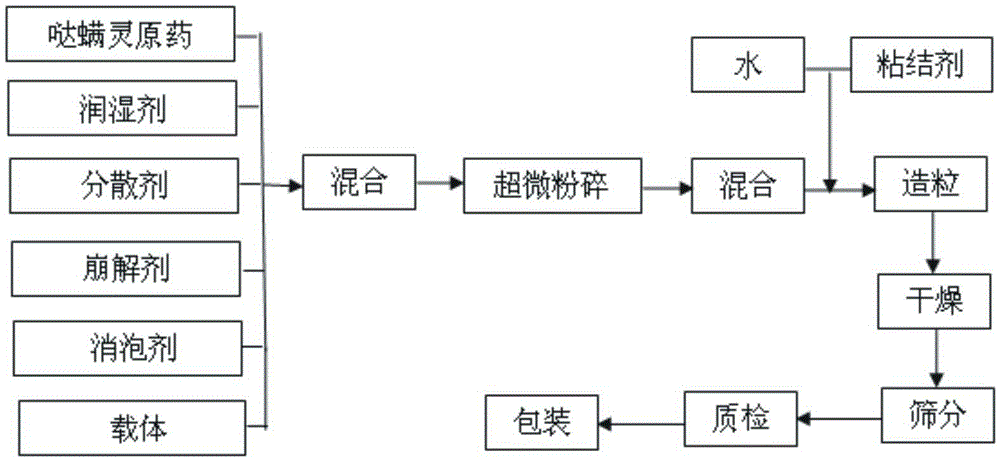

A kind of herbicide composition containing metazafen-sulfone and rimsulfuron-methyl carboxamido

ActiveCN109730080BImprove weed control effectEasy to solveBiocideAnimal repellantsBidens pilosaSetaria viridis

The invention discloses a herbicide composition containing metazafen-sulfone and rimsulfuron-methyl carboxamide, which comprises the following active ingredients in parts by weight: 1-80 parts of metazafen-sulfone, 1-50 parts of rimsulfuron-methyl carboxamide . The invention is used for controlling annual broad-leaved weeds, gramineous weeds and sedge weeds in sugarcane fields, mainly preventing and controlling crabgrass, barnyardgrass, foxtail, daughter of a daughter, goosegrass, wild millet, Cyperus rotundum and purslane , cocklebur, black nightshade, clover, red thistle, fennel, datura, weasel petals. The present invention uses the combination of metazafen and rimsulfuron-methyl to enhance the medicinal effect of the herbicide, and the weed control effect on the sugarcane field is better than that of each component used alone, and simultaneously expands the herbicide spectrum. In addition, the herbicide combination has good safety on sugarcane and meets the safety requirements of pesticide formulations.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Water dispersion granules of pesticide, and preparation method

A water-dispersing particle of agricultural chemical contains active component, wetting agent, disperser, disintegrant chosen from sodium pyrophosphate, potassium pyrophosphate, sodium tripolyphosphate, sodium bihydrogen phosphate and polyose, adhesive, and diluent. Its preparing process is also disclosed.

Owner:新沂市中港农用化工有限公司

A kind of Thiobacterium copper water dispersible granule and preparation method thereof

ActiveCN104255716BGood control effectPromote growth and developmentBiocidePlant growth regulatorsWater dispersibleAdjuvant

The invention discloses a water-dispersible granule of thiabactin copper and a preparation method thereof. 1-30 parts of agent, 0.5-5 parts of binder, 0.5-5 parts of defoamer, 0.5-5 parts of plant growth regulator, 0.5-3 parts of synergist, and 100 parts of filler. The preparation method comprises the following steps: after uniformly mixing thiabactin and various auxiliary materials in proportion, pulverizing the mixture through a pulverizer to obtain mother powder; mixing the mother powder and binder aqueous solution evenly, granulating and forming, and drying; The dried granular matter is sieved, analyzed and inspected, and then discharged, packaged, and put into storage. Thiobacterium copper water dispersible granule of the present invention is organocopper broad-spectrum bactericide, all has better control effect to various bacterial and fungal diseases, has no pollution to crops, has no residue, and the preparation of the present invention has It has the advantages of good disintegration, high suspension rate and stable heat storage performance.

Owner:ZHEJIANG LONGWAN CHEM

Benzamid water-dispersible granule and preparation method thereof

ActiveCN103210913BSave resourcesReduce pollutionBiocideFungicidesEnvironmental engineeringSuspending Agents

The present invention relates to a zoxamide water dispersible granule and a preparation method thereof. The zoxamide water dispersible granule includes the components by weight: 10-80% of zoxamide, 1-8% of a wetting agent, 1-10% of a dispersing agent, 1-40% of a disintegrating agent, 0.3-5% of a defoaming agent, 0.5-4% of a binder and the balance a carrier. The preparation method includes: accurately weighing active ingredients, additives and the carrier according to a ratio, mixing, granulating after superfine grinding, finally analyzing, screening, and testing for storage. The zoxamide water dispersible granule helps to overcome the shortcomings of suspensions and wettable powders, has the advantages of both environmental protection and low using cost, and helps to reduce the pollution for environment in the processing and using processes and reduce the cost of farmers.

Owner:嘉善陶庄再生资源有限公司

Tribenuron-methyl water dispersible granule

InactiveCN108294038AHigh content of active ingredientsFast disintegrationBiocideAnimal repellantsWater dispersibleTribenuron-methyl

The invention discloses a tribenuron-methyl water dispersible granule. The tribenuron-methyl water dispersible granule comprises tribenuron-methyl raw powder, a wetting agent, a dispersing agent, a disintegrating agent, an emulsifying agent, a stabilizing agent and filler, wherein the content of the tribenuron-methyl raw powder is 78.9%, the content of the dispersing agent is 5%-5.5%, the contentof the wetting agent is 4%-4.5%, the content of the emulsifying agent is 2.5%-3%, the content of the disintegrating agent is 3%-3.5%, the content of the stabilizing agent is 3%-3.5%, and the balance of the filler. The prepared water dispersible granule is 75% tribenuron-methyl water dispersible granule, the content of active components is high, the environmental pollution is small, the disintegrating speed is high, the dispersing performance is good, and the heat storage performance is stable.

Owner:ZHEJIANG PIONEER CROPSCI CO LTD

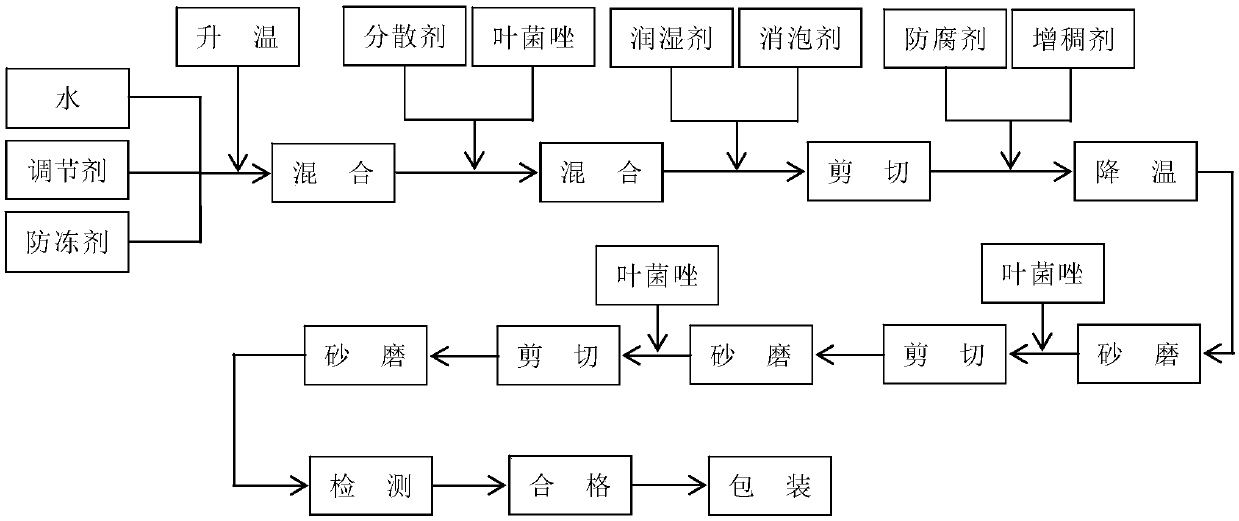

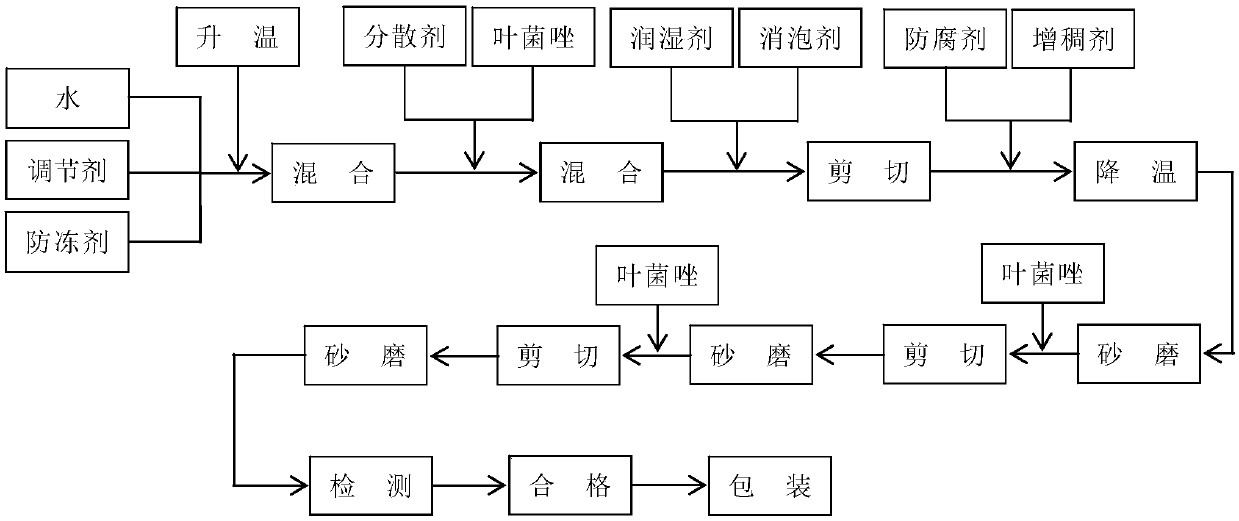

Metconazole water suspension bactericide capable of adjusting crop physique, and preparation method thereof

InactiveCN111109250AReduce use costReduce pollutionBiocidePlant growth regulatorsPreservativeToxicology

The invention discloses a metconazole water suspension bactericide capable of adjusting crop physique. The metconazole water suspension bactericide comprises the following components: 5-70 wt% of metconazole raw medicine, 1-15 wt% of a dispersing agent, 0.1-10 wt% of a wetting agent, 0.5-10 wt% of a thickening agent, 0.5-10 wt% of an anti-freezing agent, 0.01-0.3 wt% of a conditioning agent, 0.01-3 wt% of a preservative, 0.01-0.5 wt% of a defoaming agent and the balance of water. The metconazole water suspension bactericide overcomes the defects of wettable powder, and has the advantages of environmental protection and low use cost. In the processing and using process, pollution to the environment is reduced, the safety of a user is improved, the using cost of farmers is reduced, and the method is the development trend of pesticide preparations at present.

Owner:JIANGSU SWORD AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com