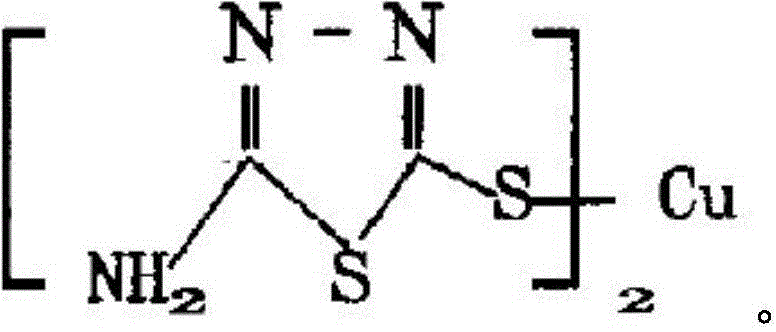

A kind of Thiobacterium copper water dispersible granule and preparation method thereof

A technology of thiophanate copper and dispersible granules, which is applied in the fields of botanical equipment and methods, fungicides, biocides, etc., can solve the problems of poor disintegration and low suspension rate, and achieves less application times, good control effect, and reduced use. The effect of frequency and dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 110

[0053] Embodiment 1 10% thiabendin copper water dispersible granule

[0054] Step 1. Preparation of aqueous binder solution: put a certain amount of water into a spiral mixer and heat to 70-90°C, then add 3 parts of polyvinyl alcohol, stir for at least 1 hour, and set aside for later use;

[0055] Step 2. Preparation of the product: 10 parts of Thiobacterium copper, 6 parts of vinyl ether sulfate, 8 parts of sodium methylene bis-naphthalene sulfonate, 20 parts of phenyl salicylate, 4 parts of dextrin, polyether disinfectant 1 part of foaming agent, 3 parts of sodium nitrophenolate, 0.5 part of pine ester-based vegetable oil, the prepared aqueous binder solution and high clay make up to 100 parts, put it into a mixing kettle or a shearing kettle, and mix it into a uniform slurry. Then it is ground by a sand mill for 10-150 minutes, filtered to remove the sand grinding medium, and finally sprayed and granulated by a pressure spray drying tower, screened, analyzed and tested, and...

Embodiment 215

[0057] Embodiment 2 15% Thiobacterium Copper Water Dispersible Granules

[0058] Step 1. Preparation of Thiobacterium copper parent powder: Weigh 15 parts of Thiobacterium copper, 7 parts of alkylnaphthalene sulfonate, 8 parts of polymer carboxylate, 30 parts of sodium chloride, and 4 parts of polyether defoamer in parts by weight. 1 part, 4 parts of diethyl hexanoate, 2 parts of Silwet L-700, 95 parts of high clay, put into the spiral mixer and mix for 15-20 minutes, adjust the speed of the classifier and the feeder, and then turn on the jet mill for Airflow crushing, the crushed material enters the gravity-free mixer, and mixes again for 20-30 minutes, after the particle size is detected to be less than 10 microns, the material is discharged and set aside;

[0059] Step 2. Preparation of aqueous binder solution: Put a certain amount of water into a spiral mixer and heat to 70-90°C, then add 5 parts of polyvinyl alcohol, stir for at least 1 hour, and set aside for later use; ...

Embodiment 325

[0062] Embodiment 3 25% Thiobacterium Copper Water Dispersible Granules

[0063] Step 1. Preparation of Thiobacterium Copper Mother Powder: 25 parts of Thiobacterium Copper, 0.5 parts of Brassin, 6 parts of Sodium Lauryl Polyoxyethylene Ether Sulfate, 25 parts of Sodium Chloride, and 2 parts of Fatty Alcohol Polyoxyethylene Ether , 4 parts of silicone defoamer, 3 parts of palm kernel oil fatty acid methyl ester, 97 parts of pottery clay, put into the screw mixer and mix for 15-20 minutes, adjust the speed of classifier and feeder, and then turn on the jet mill Carry out airflow crushing, and the crushed material enters the gravity-free mixer and mixes again for 20-30 minutes. After the particle size is detected to be below 10 microns, the material is discharged and set aside;

[0064] Step 2. Preparation of binder aqueous solution: put a certain amount of water into a spiral mixer and heat to 70-90°C, then add 3 parts of binder, stir for at least 1 hour, and set aside for late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wettability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com