Water dispersion granules of pesticide, and preparation method

A technology of dispersible granules and pesticide water, which is applied in the field of pesticides, can solve the problem of late emergence of water dispersible granule dosage forms, and achieve the effects of good dispersibility, high performance and high suspension rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

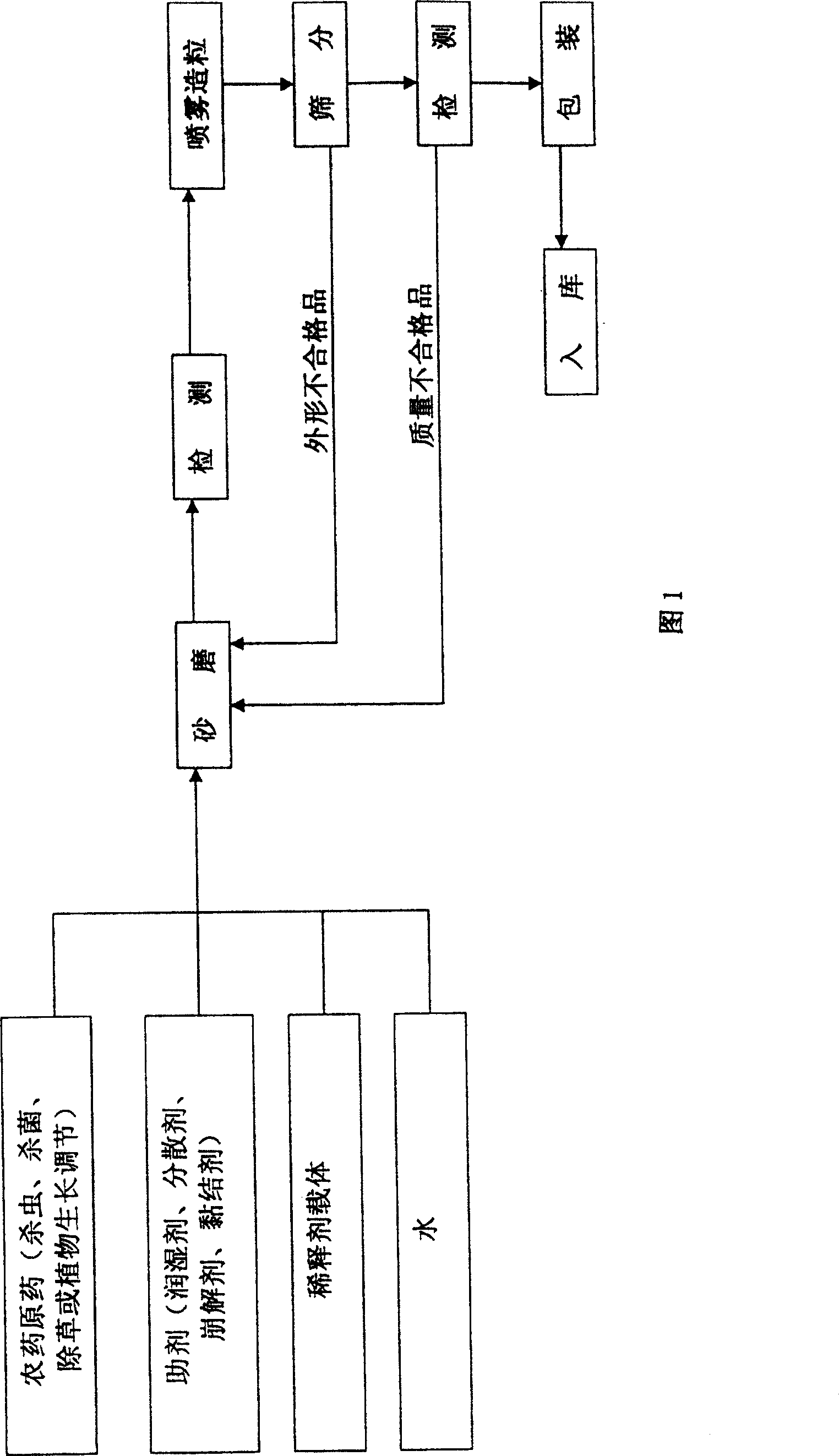

[0055] Embodiment 1 70% thiophanate-methyl water-dispersible granules

[0056] Weigh the original powder of thiophanate-methyl (content > 98%) to account for 71%, the wetting agent di-n-propylnaphthalene sulfonate accounts for 4%, and the dispersant accounts for 1% of cresol-formaldehyde and sodium sulfite condensate. %, disintegrant sodium pyrophosphate accounts for 2%, binder gum arabic accounts for 1%, stabilizer polyoxyethylene ether 2%, and then fills up to 100% (mass content) with diluent carrier kaolin. Processing method: spraying method - the above-mentioned raw powder, wetting agent, dispersant, disintegrating agent, binder, stabilizer and diluent carrier are processed into a suspending agent by a sand mill or a sand mill kettle according to the formula and then sprayed Granulate, sieve and test to obtain 70% thiophanate-methyl water-dispersible granules with a pass rate of about 98%. After testing, the active ingredient content is 70.3%, moisture 99%, suspension rat...

Embodiment 2

[0057] Embodiment 2 75% bensulfuron-methyl water-dispersible granules

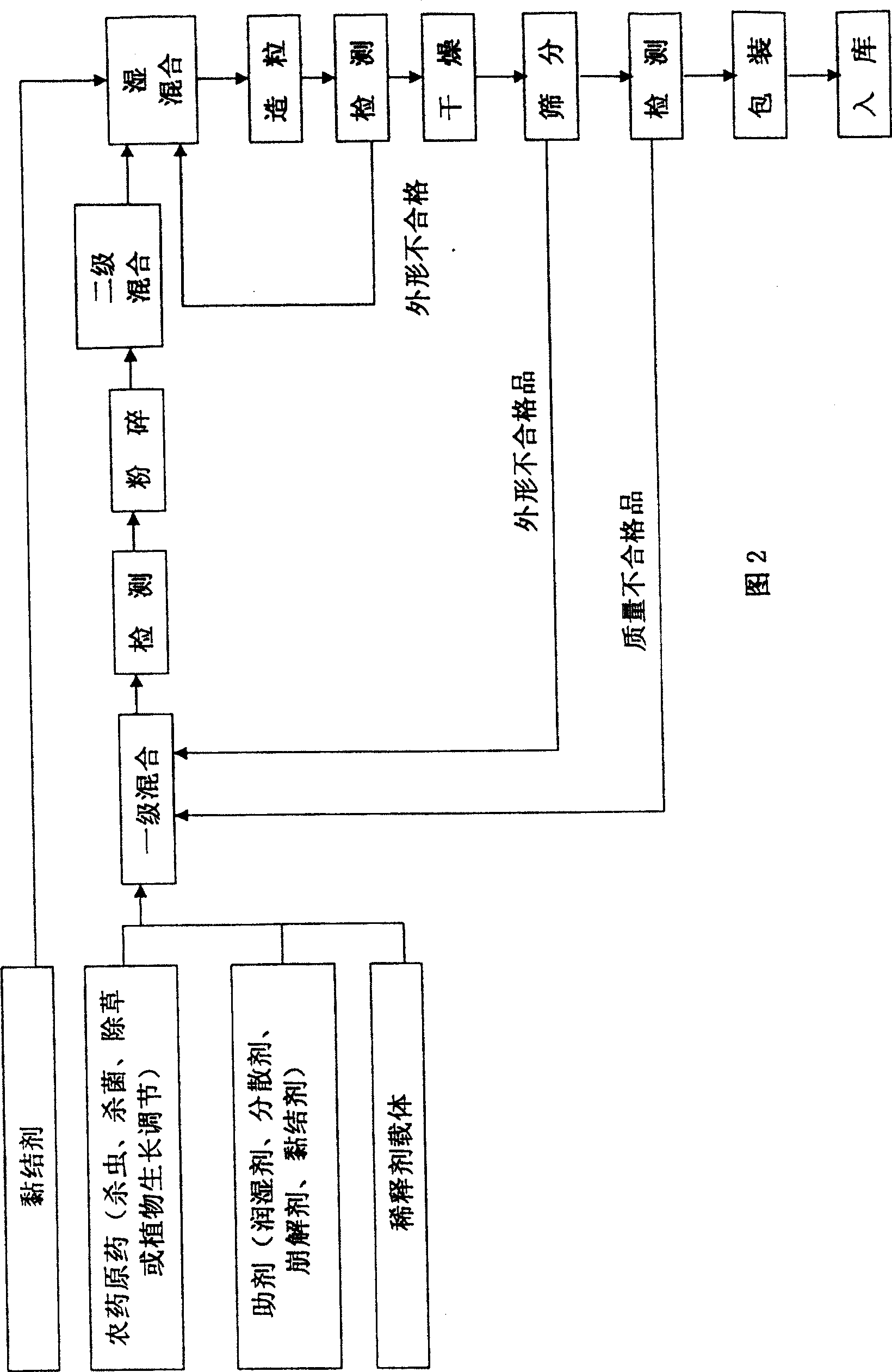

[0058]Weigh the original powder of bensulfuron-methyl (content > 95%) and the percent content ratio accounts for 76%, the wetting agent fatty amide N-methyl taurate accounts for 2%, and the dispersant agent sodium naphthalenesulfonate formaldehyde condensate accounts for 3%. %, disintegrant lactose 8%, binder methyl cellulose accounts for 2%, stabilizer sodium alkylbenzene sulfonate 1%, and then fill up to 100% (mass content) with diluent carrier kaolin. Processing method: Extrusion method - mix the above raw powder, wetting agent, dispersant, disintegrant, stabilizer and diluent carrier according to the formula, mix them evenly in a mixer, process and pulverize them to make mother powder, and then make mother powder Mix evenly with the binder, granulate through extrusion equipment, dry, screen, and test to obtain 75% bensulfuron-methyl water-dispersible granules with a pass rate of about 97%. After testi...

Embodiment 3

[0059] Embodiment 3 25% emamectin benzoate water dispersible granules

[0060] Weighing emamectin benzoate (content>60%) percent content ratio accounts for 25.5%, wetting agent benzyl naphthalene sulfonate accounts for 6%, and the dispersant SS of dispersant Hearst Company accounted for 5%, disintegrant sodium tripolyphosphate 2%, binder polyvinylpyrrolidone accounted for 5%, stabilizer polyoxyethylene ether 5%, and then filled up to 100% (mass content) with diluent carrier white carbon black. Processing method: Extrusion method - mix the above raw powder, wetting agent, dispersant, disintegrant, stabilizer and diluent carrier according to the formula, mix them evenly in a mixer, process and pulverize them to make mother powder, and then make mother powder Mix evenly with the binder, granulate through extrusion equipment, dry, screen, and detect to obtain 25% emamectin benzoate water-dispersible granules with a pass rate of about 98%. After testing, the active ingredient cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com