Thiophthanate methyl water dispersible granula

A thiophanate-methyl, dispersive technology, applied in the field of thiophanate-methyl water-dispersible granules and its component content, can solve the problems of endangering human health, high use cost, environmental pollution, etc., and achieve low environmental pollution , High content of active components, high bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

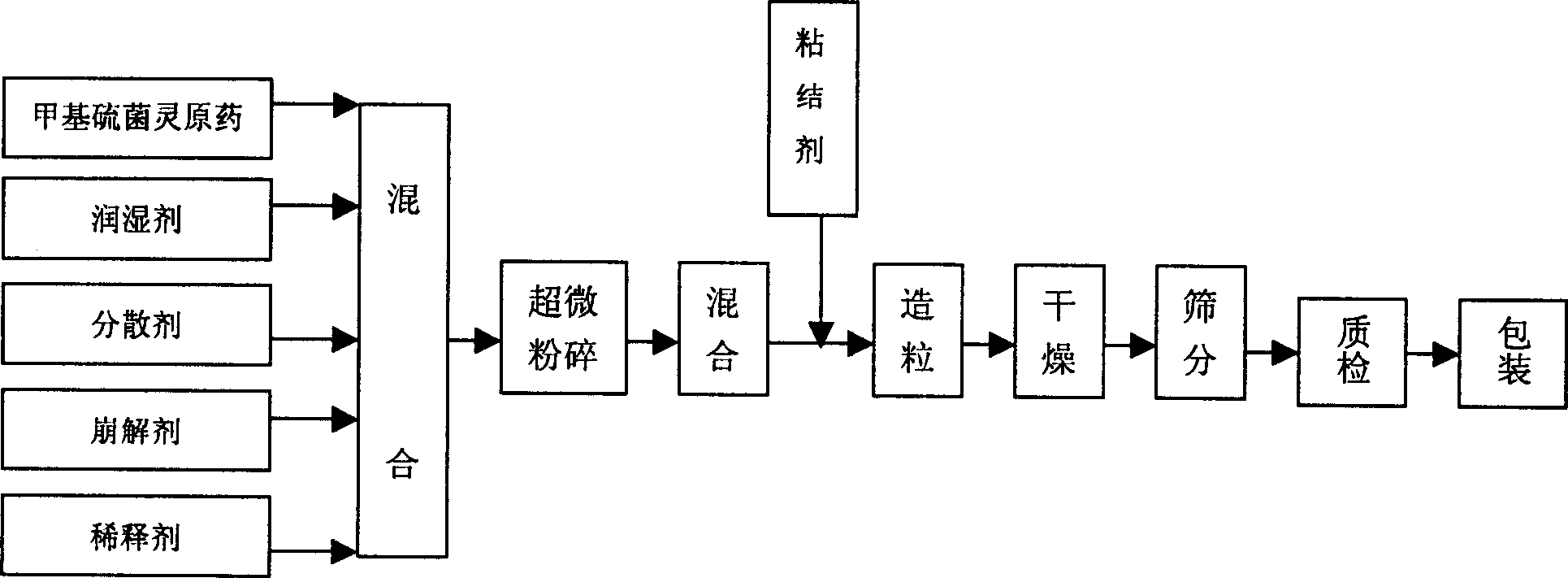

Method used

Image

Examples

Embodiment 1

[0021] Weigh 72% of thiophanate-methyl raw powder, 3% of wetting agent phenylethylphenol polyoxyethylene ether formaldehyde, 6% of dispersant sodium lignosulfonate, 5% of sodium sulfate, and 8% of diluent light calcium carbonate , mix it according to the general method, after stirring evenly, pulverize it through a jet mill to obtain mother powder, mix the mother powder with 6% binder-modified sodium polyacrylate 80, then granulate, dry, and sieve to obtain about 96% 70% thiophanate-methyl water dispersible granules. After testing, the active ingredient content is 70.8%, the moisture content is ≤2.5%, the pH value is 7.1, the sieving (through a 75μm sieve) is ≥98%, the suspension rate is ≥65%, the persistent foaming property (1min)≤10mL, and the wettability≤1min , dust ≤ 3.0%, accelerated thermal storage stability qualified. In practice, the dosage for preventing and treating apple tree spot defoliation is 700-875 mg / kg, and the control effect is 78-98%.

Embodiment 2

[0023] Weigh 73% of the original powder of thiophanate-methyl, 4% of sodium methylene bis-naphthalene sulfonate as a wetting agent, 5% of sodium polycarboxylate as a dispersing agent, 6% of white carbon black as a disintegrating agent, and 8% of diatomaceous earth as a diluent %, after mixing it evenly, it is pulverized by an airflow mill to obtain the mother powder, and the mother powder is mixed with 4% polyethylene glycol No. 72 binder evenly, then granulated, dried, and sieved to obtain about 96% of the 70% thiophanate-methyl water-dispersible granules. After inspection, the active ingredient content is 71.1%, moisture ≤ 2.5%, PH value 7.4, sieving (through 75μm sieve) ≥ 98%, suspension rate ≥ 65%, persistent foaming (1min) ≤ 10mL, wettability ≤ 1min , dust ≤ 3.0%, accelerated thermal storage stability qualified. The dosage for preventing and treating apple tree spot defoliation is 700-875 mg / kg, and the control effect is 81-90%.

Embodiment 3

[0025] Weigh 53% of thiophanate-methyl raw powder, 6% of sodium phenylethylphenol polyoxyethylene ether sulfate as a wetting agent, 6% of sodium lignosulfonate as a dispersing agent, 8% of attapulgite as a disintegrating agent, and kaolin as a diluent 20%, after mixing it evenly, it is pulverized by a jet mill to obtain the mother powder, and the mother powder is mixed with 7% polyethylene glycol No. 72 binder, then granulated, dried, and sieved to obtain about 97% 50% thiophanate-methyl water dispersible granules. After inspection, the active ingredient content is 52.7%, the moisture content is ≤2.5%, the pH value is 7.3, the sieving (through a 75μm sieve) is ≥98%, the suspension rate is ≥65%, the persistent foaming property (1min) is ≤10mL, and the wettability is ≤1min , dust ≤ 3.0%, accelerated thermal storage stability qualified. The dosage for preventing and treating apple tree spot defoliation is 700-875 mg / kg, and the control effect is 78-96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com