Concrete formwork for real estate construction

A technology of concrete formwork and real estate, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of concrete formwork tilting under force, affecting the effect of pouring, concrete formwork extrusion, etc. Achieve the effect of improving the pouring effect, facilitating support, and reducing customized processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

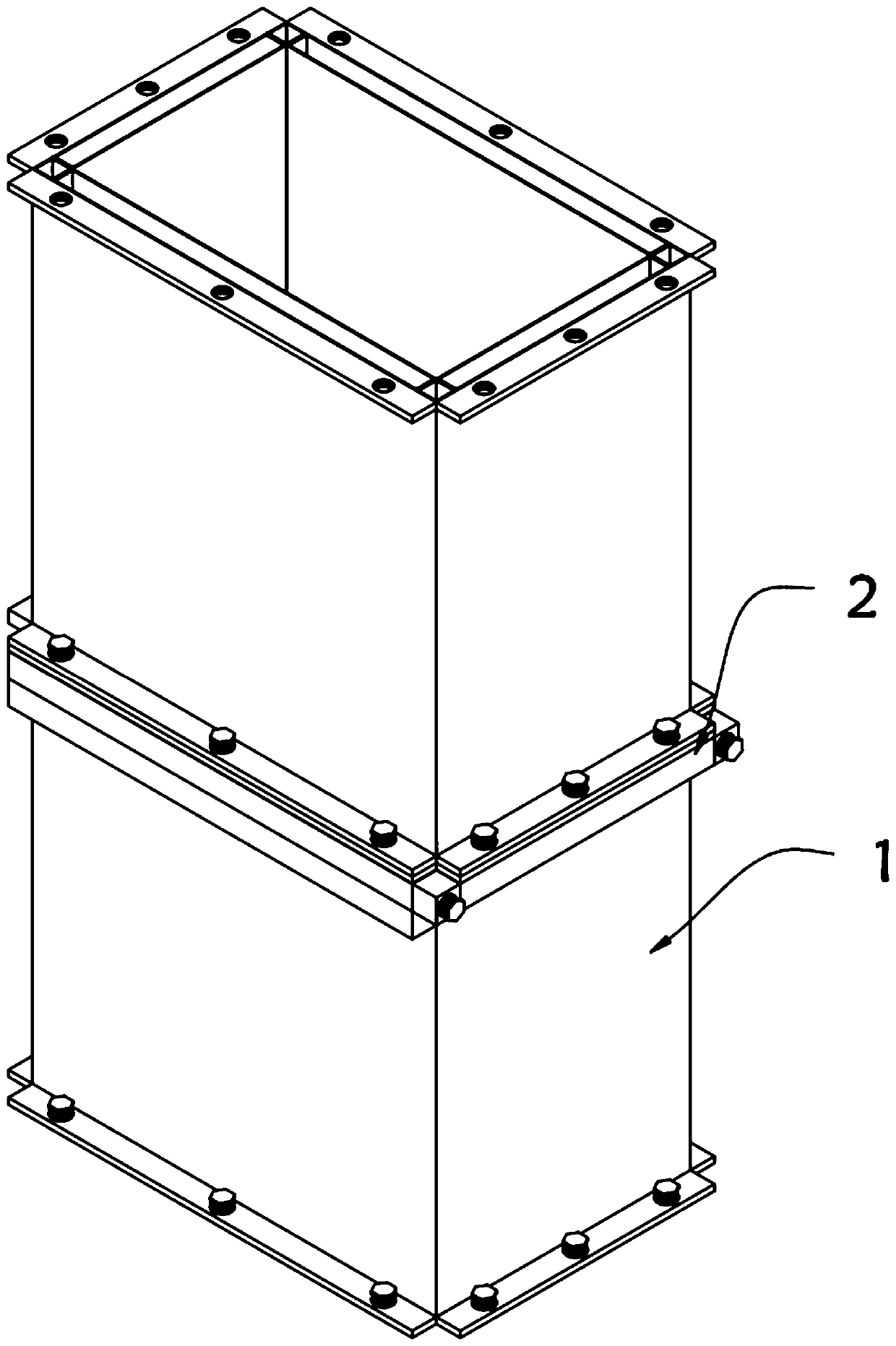

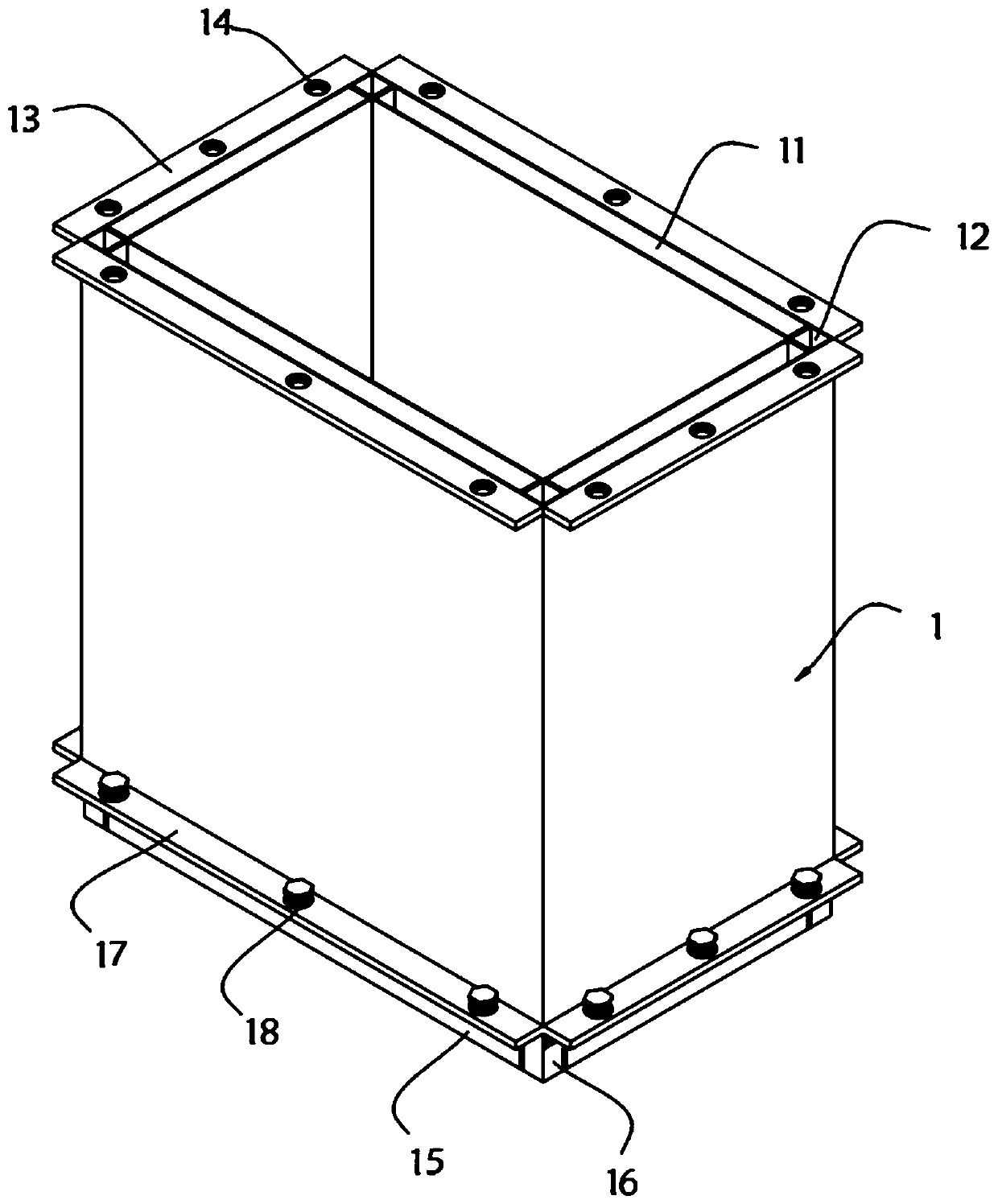

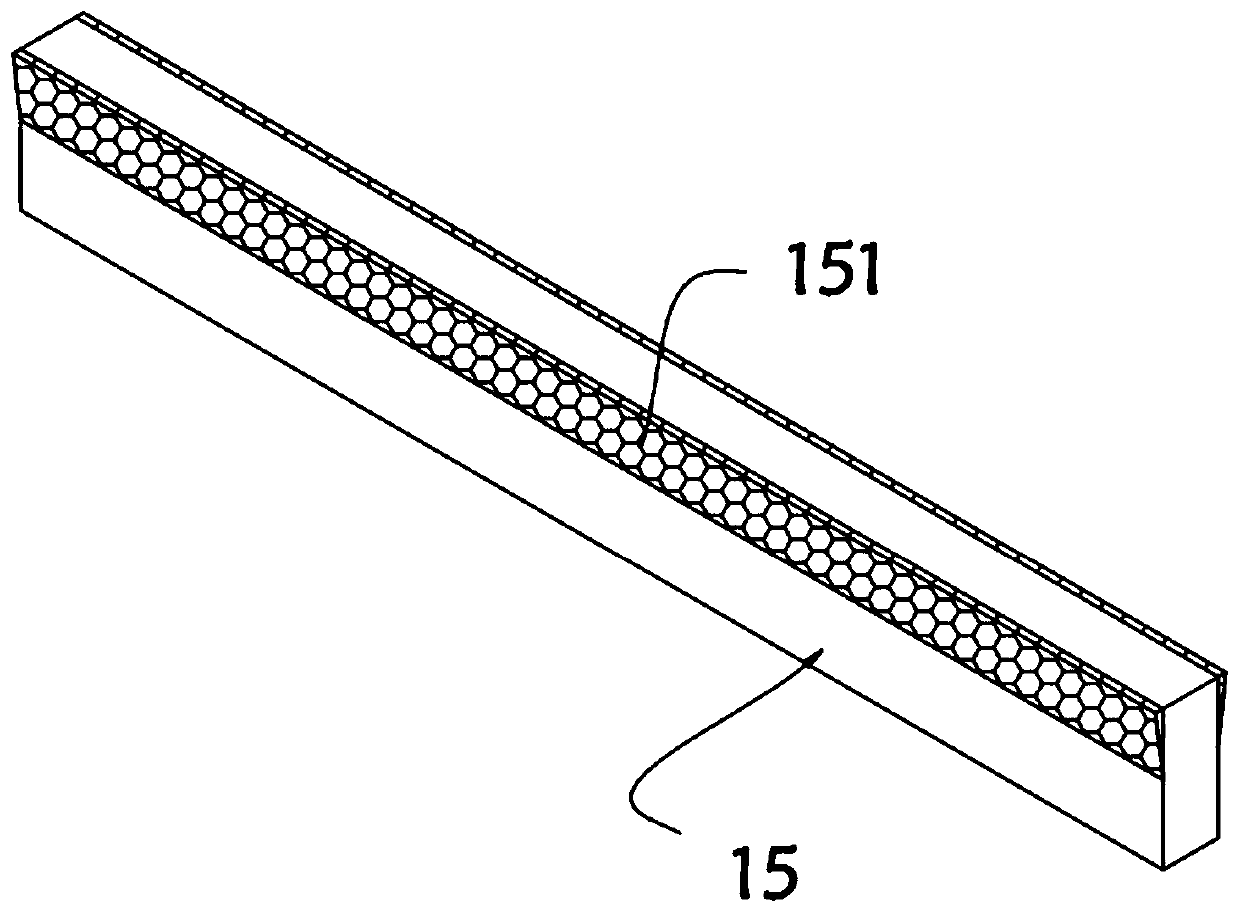

[0037] In one aspect, the present invention provides a concrete formwork for real estate construction, such as Figure 1-Figure 4 As shown, it includes a concrete formwork body 1 and fasteners 2 for assembling the concrete formwork body 1, connecting grooves 11 are opened around the top of the concrete formwork body 1, and positioning grooves 12 are arranged between the two connecting grooves 11. The outer walls around the top of the formwork body 1 are respectively equipped with upper outer edge plates 13, and the outer surface of the upper outer edge plate 13 is provided with a plurality of positioning screw grooves 14, and the bottom of the concrete formwork body 1 is respectively equipped with connecting plates 15, two connecting plates 15 Positioning plates 16 are installed between them, the outer walls around the bottom of the concrete formwork body 1 are respectively equipped with lower outer edge plates 17, the outer surface of the lower outer edge plate 17 is equipped ...

Embodiment 2

[0044] As a second embodiment of the present invention, in order to facilitate the tight connection of the concrete formwork bodies 1 when combined and installed, the inventors provided fasteners 2 at the connection between the two concrete formwork bodies 1, as a preferred implementation For example Figure 5-7 As shown, the fastener 2 includes a pair of first clamping plates 21, a pair of second clamping plates 22 are installed between the two first clamping plates 21, and a plurality of connecting screw grooves 211 are opened on the top of the first clamping plates 21. , the center positions of both ends of the first clamping plate 21 are provided with clamping screw grooves 212, and both sides of the clamping screw grooves 212 are respectively provided with slots 213, and both sides of the second clamping plate 22 are respectively equipped with clamping blocks 221. The central position of block 221 is equipped with locking bolt 222, and the both sides of locking bolt 222 a...

Embodiment 3

[0050] As a third embodiment of the present invention, in order to facilitate the support of the concrete formwork body 1 during assembly, the inventors improved the structure of the support plate 23, as a preferred embodiment, such as Figure 8 and Figure 9 As shown, the bottom of the first clamping plate 21 is equipped with a support plate 23, and the inside of the support plate 23 is provided with a mounting groove 231, and the two sides of the inner wall of the mounting groove 231 are respectively equipped with card holders 232, and the center of the mounting groove 231 is provided with a spacer. Plate 233, the two ends of dividing plate 233 are respectively equipped with hinged seat 234, and hinged seat 234 is hinged with supporting tube 235, and the inwall of supporting tube 235 is provided with internal thread 236, and the inside of supporting tube 235 is provided with stud 237, and stud One end of 237 is provided with a mounting plate 238, the mounting plate 238 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com