Nuclear power station steel containment vessel top head assembling bracket and assembling method

A technology of steel containment and top sealing head, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of complex structure of assembled brackets, achieve the effects of repeated use, weight reduction, and use cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

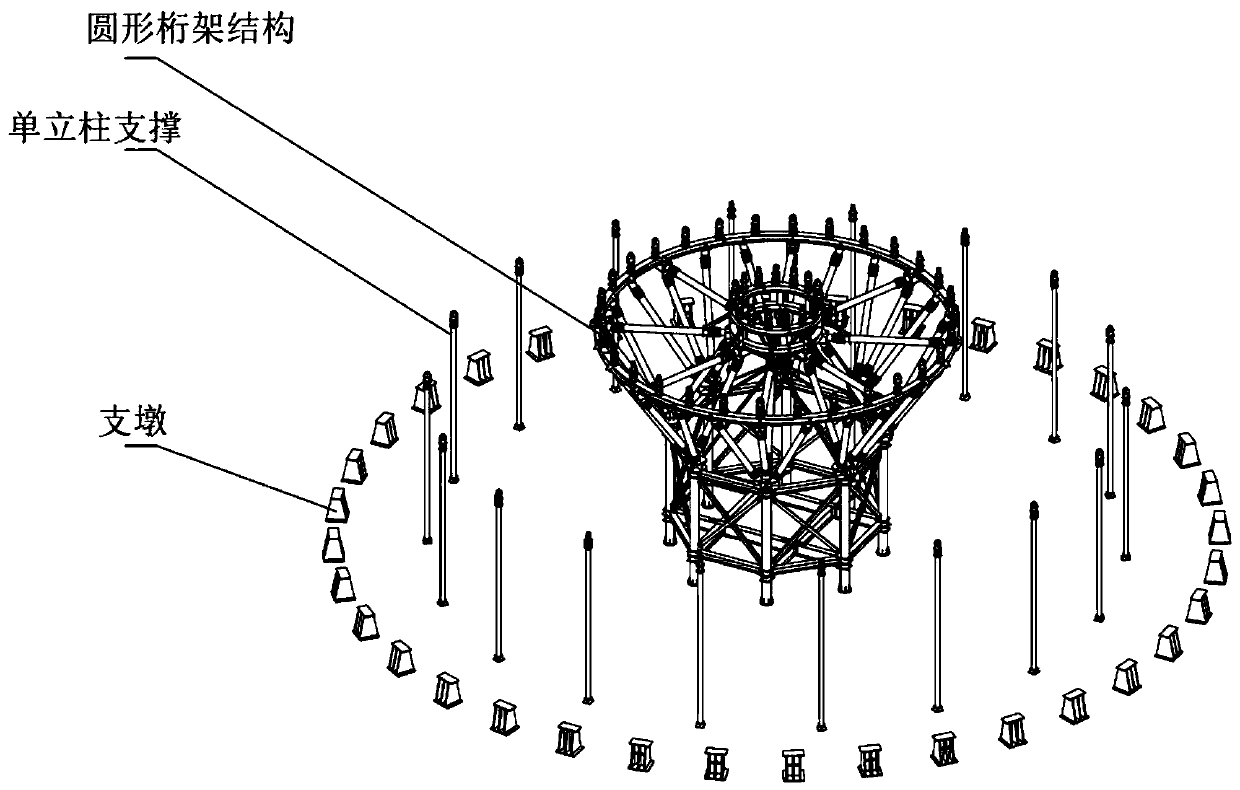

[0045] Disclosed in one or more embodiments is a nuclear power plant steel containment top seal assembly bracket, such as image 3 As shown, it includes: buttresses and single column supports for assembling the first ring of head plates, and circular truss structures for assembling the second, third, and fourth rings of head plates.

[0046] Among them, the supporting pier and the single column support are used to assemble the head plate of the first circle, and one end of the head plate is supported on the pier,

[0047] After the single column support is connected to the head plate of the first circle, the head plate is hoisted. The single column support is hoisted together with the head plate of the first circle. The anchor plates on the ground are connected and fixed, and each single column support corresponds to at least two buttresses.

[0048] The single column support can be dismantled after the first round of head plate assembly is completed, without affecting the su...

Embodiment 2

[0056] In one or more embodiments, a method for assembling a nuclear power plant steel containment top seal head is disclosed, including the following steps:

[0057] Before the top head is assembled, the pier of the first ring of head plate and the circular truss structure of the inner ring are fixed and installed according to the predetermined position;

[0058] The single column support is hoisted simultaneously with the head plate of the first circle, and the single column support is connected and fixed with the ground anchor plate after the head plate is hoisted to the outer ring pier;

[0059] like Figure 6 As shown, the first ring head plate is assembled using a single column and the "insertion method". The two head plates with columns are hoisted first and then inserted into the middle plate. The first ring head plate is assembled in this order. assembly.

[0060] After the first round of head plate welding is completed, the single column support can be removed. The...

Embodiment 3

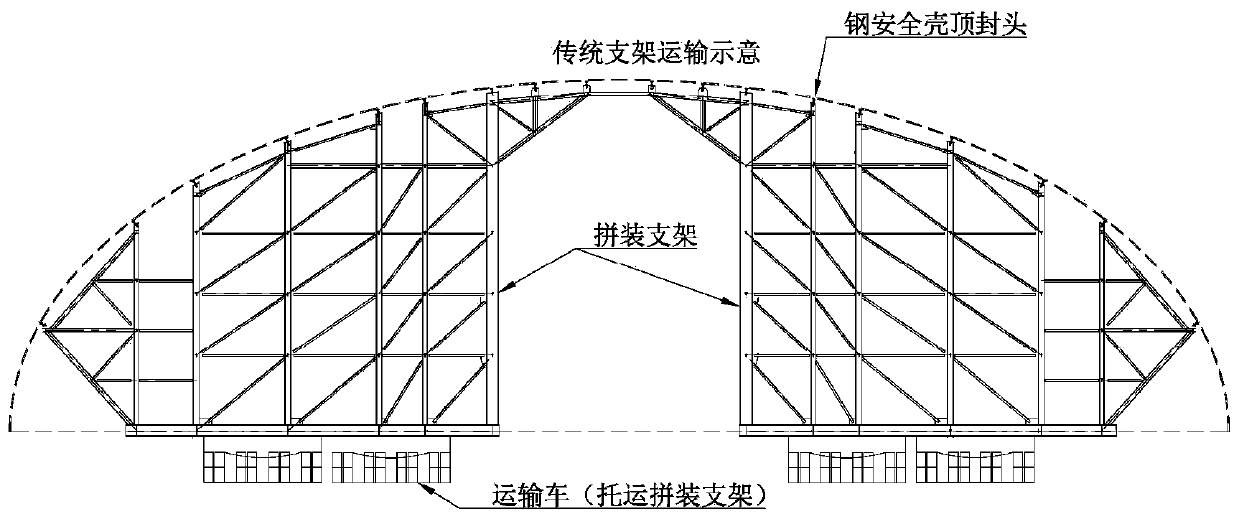

[0064] In some other embodiments, before the top seal head is transported, the connection structure between the bottom of the circular truss structure and the foundation is removed, and a single group of transport vehicles is used to lift the circular truss structure, and four sets of transport vehicles are used to transport the top of the containment head; such as Figure 7 and Figure 8 As shown, the circular truss structure and the containment top head are transported synchronously. When the containment top head reaches the hoisting position, the containment top head is hoisted. After the top head is hoisted, the circular truss structure can pass through the bottom transport vehicle Shipped separately to designated location for reuse. The circular truss structure and the transportation method of this embodiment do not need to disassemble and assemble the circular truss structure, so that it can be reused as a whole, saving a lot of time for disassembly and assembly, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com