An engine thrust chamber performance test device for a variable thrust rocket engine

A rocket engine and test device technology, which is applied in the direction of rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as the inability to do fluid flow performance tests with back pressure, and achieve the effect of pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

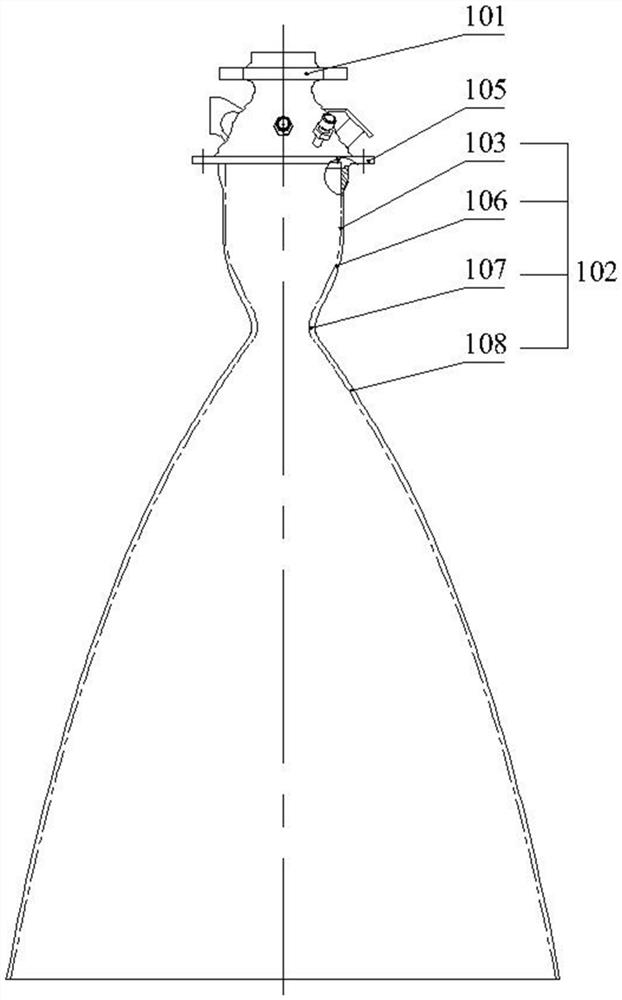

[0052] Embodiment 1, this embodiment is suitable for testing the engine thrust chamber of the short nozzle state of the variable thrust rocket engine.

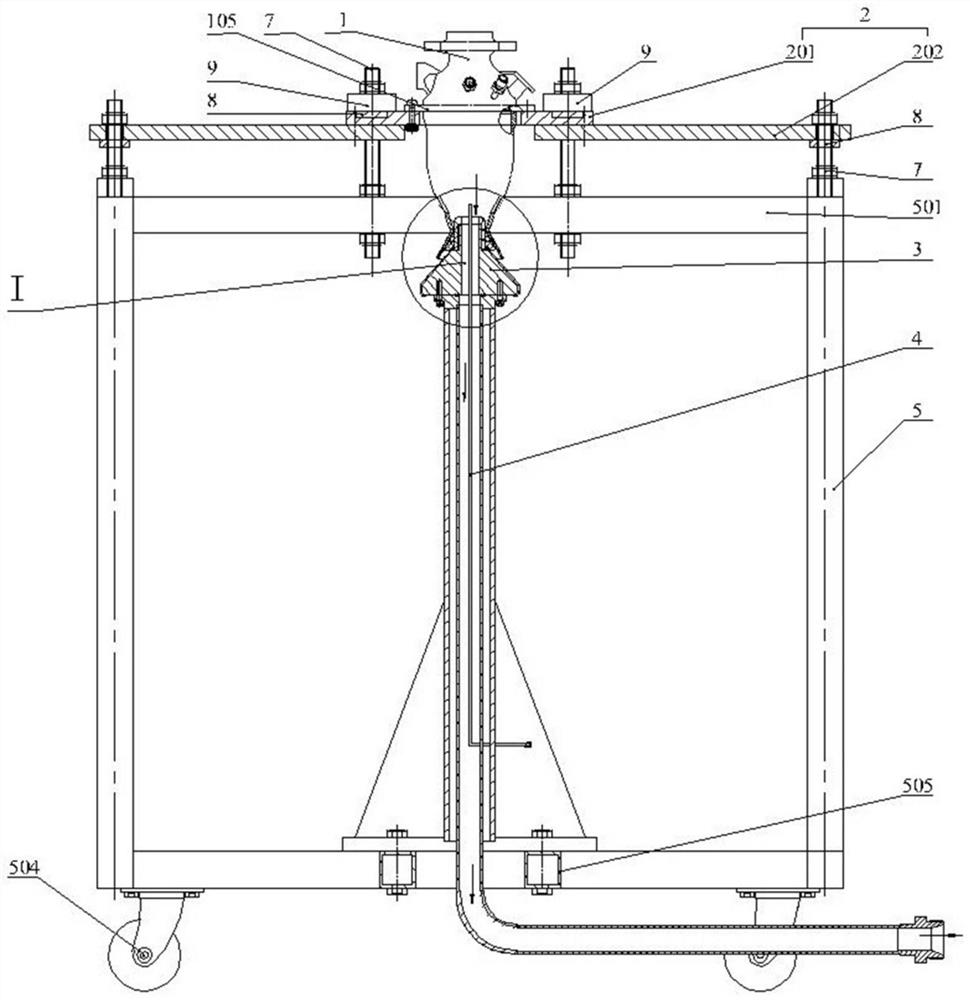

[0053] refer to figure 2 and image 3 , the engine thrust chamber performance test device for a variable thrust rocket engine includes an anti-top assembly 2, a throat support assembly 3, a bottom support assembly 4, a stand 5 and a strip-shaped pressure plate 9.

[0054] refer to Figure 8 to Figure 10 , the stand 5 includes an upper frame 521 , a lower frame 522 and four columns 502 supported between the upper frame 521 and the lower frame 522 . The four sides of the stand 5 are provided with transparent plexiglass plates 509 to prevent water from splashing during the test and to facilitate observation of the test conditions. The transparent plexiglass plate 509 is inserted in the thin strip 513 with a bottom surface spot-welded on the outside of the column 502 . The bottom of the lower frame 522 is provided with four u...

Embodiment 2

[0064] Embodiment 2, this embodiment is suitable for testing the engine thrust chamber of the variable thrust rocket engine with tail nozzle state.

[0065] refer to Figure 11 , the difference between this embodiment and embodiment 1 is only:

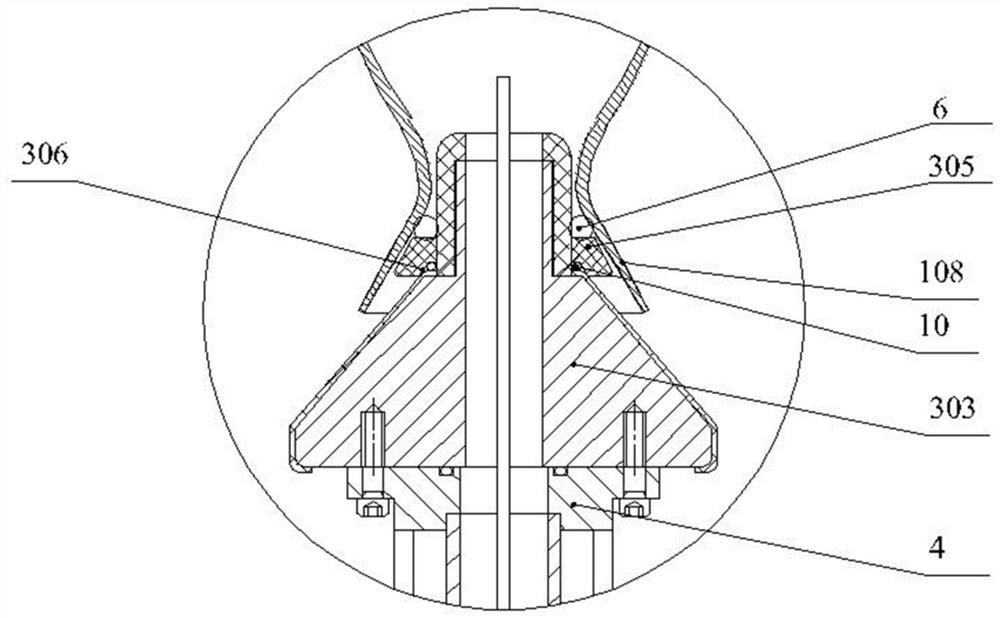

[0066] In this embodiment, the height of the support ring 305 is higher. In order to raise the engine thrust chamber 1 and prevent the engine thrust chamber tail nozzle inner wall from contacting the throat support assembly 3 and scratching and scratching the engine thrust chamber, the support ring 305 The upper part is a cylinder 307, the lower part is a circular platform, and the upper end surface forms a sealing ring positioning groove, and two first sealing members 6 and third sealing members 11 of different sizes are placed. The engine thrust chamber 1 can achieve sealing when it contacts any sealing ring. As a result, setting two sealing rings has an axial positioning effect on the product and prevents the product from swinging ...

Embodiment 3

[0067] Embodiment 3, this embodiment is suitable for testing the small-sized throat engine thrust chamber of the variable thrust rocket engine.

[0068] refer to Figure 12 , the difference between this embodiment and embodiment 1 is only:

[0069] In this embodiment, the height of the support ring 305 is higher, and the upper end surface of the support ring 305 is provided with a slightly smaller first sealing ring 6 to adapt to the sealing size of the inner wall of the thrust chamber of the engine to achieve a sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com