Riveting water storage tank and manufacturing method thereof

A technology for water storage tanks and manufacturing methods, applied to lighting and heating equipment, fluid heaters, etc., can solve problems such as low pressure resistance, high defect rate, and difficult welding of water storage tanks, so as to improve pressure resistance and reduce Water leakage, guaranteed service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

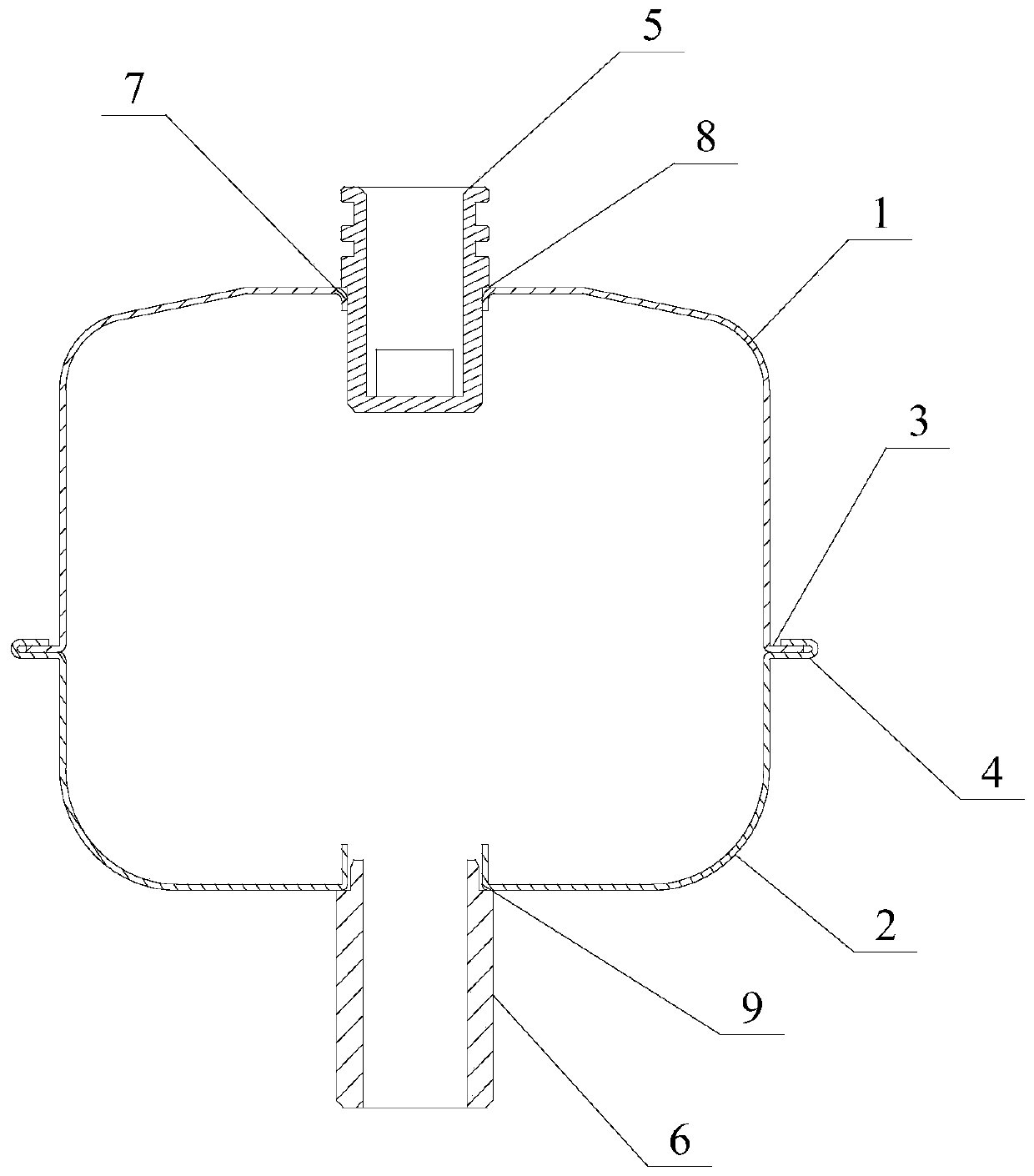

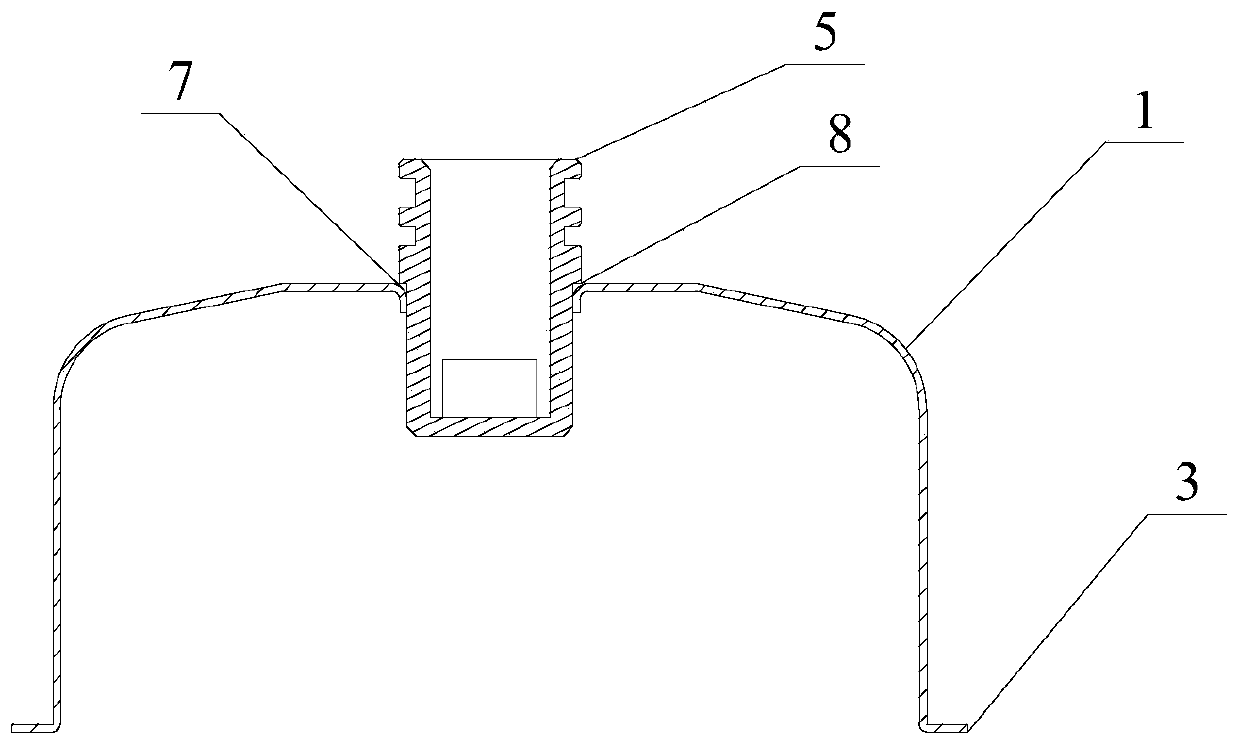

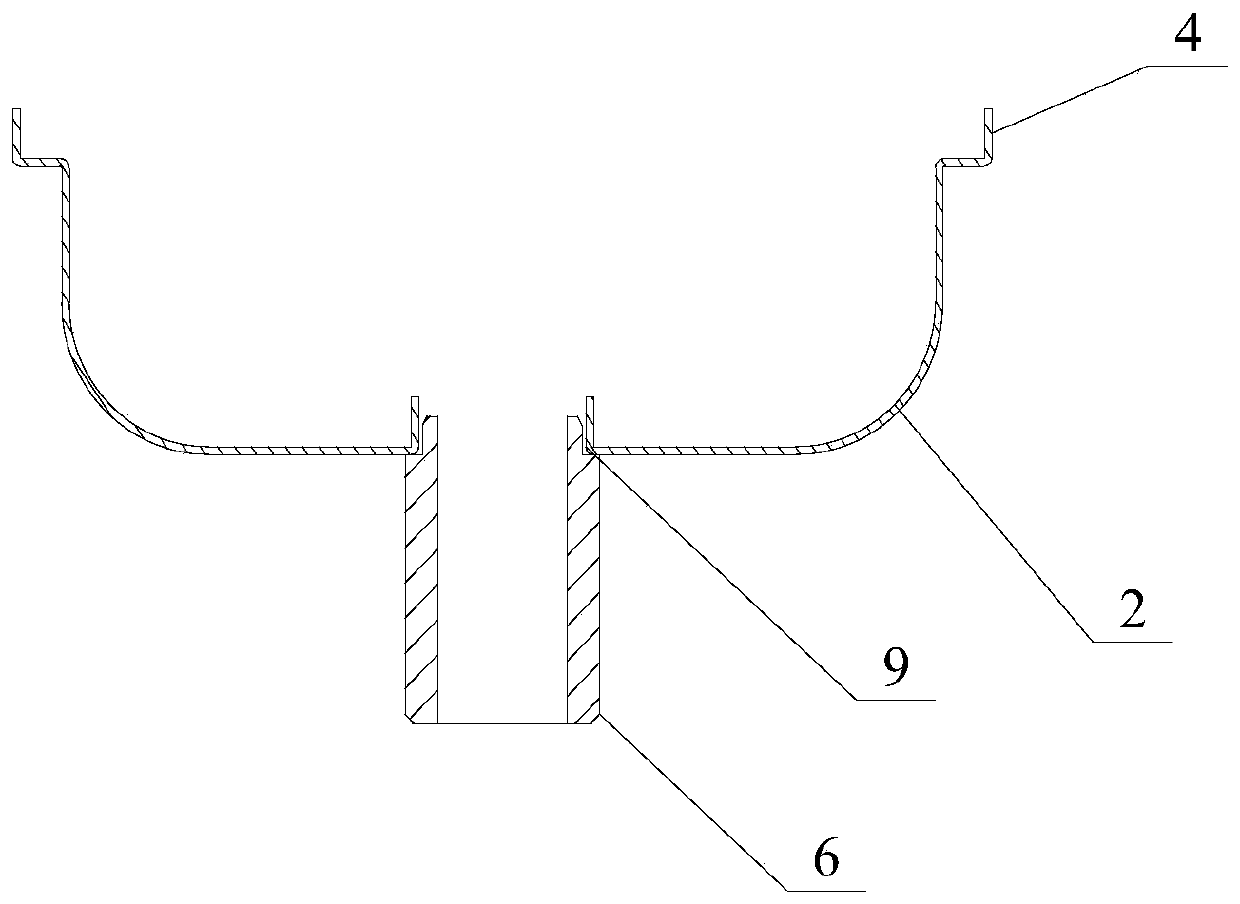

[0035] The invention provides a riveted water storage tank, which can be made into a water storage tank by riveting, simplifies the structure, and improves the pressure resistance effect of the tank body. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as Figure 1 to Figure 5 As shown, a riveted water storage tank provided by the present invention includes an upper tank body 1 and a lower tank body 2 that are fastened and connected to each other. The connecting end of 2 is bent outward to form a gusset 4, the gusset 4 is a U-shaped folded plate, which wraps around the ring-shaped folded plate 3 and is fixed by riveting. The riveted water storage tank also includes:

[0037] The water inlet pipe 5 is inserted from the top of the upper tank body 1 and fixed by welding, and is used to add water to the water storage tank, and at least two through holes are opened on the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com