Ultrasonic transceiving processing module, ultrasonic detector, and method for detecting grouting fullness of prefabricated component sleeve

A technology for processing modules and detectors, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, processing detection response signals, and use of sound waves/ultrasonic waves/infrasonic waves to analyze solids. problem, to achieve the effect of low cost, small residual vibration of the probe, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The specific implementation of the ultrasonic transceiver processing module, the ultrasonic detector, and the method for detecting the grouting fullness of the prefabricated component sleeve of the present invention will be described in detail below in conjunction with the accompanying drawings.

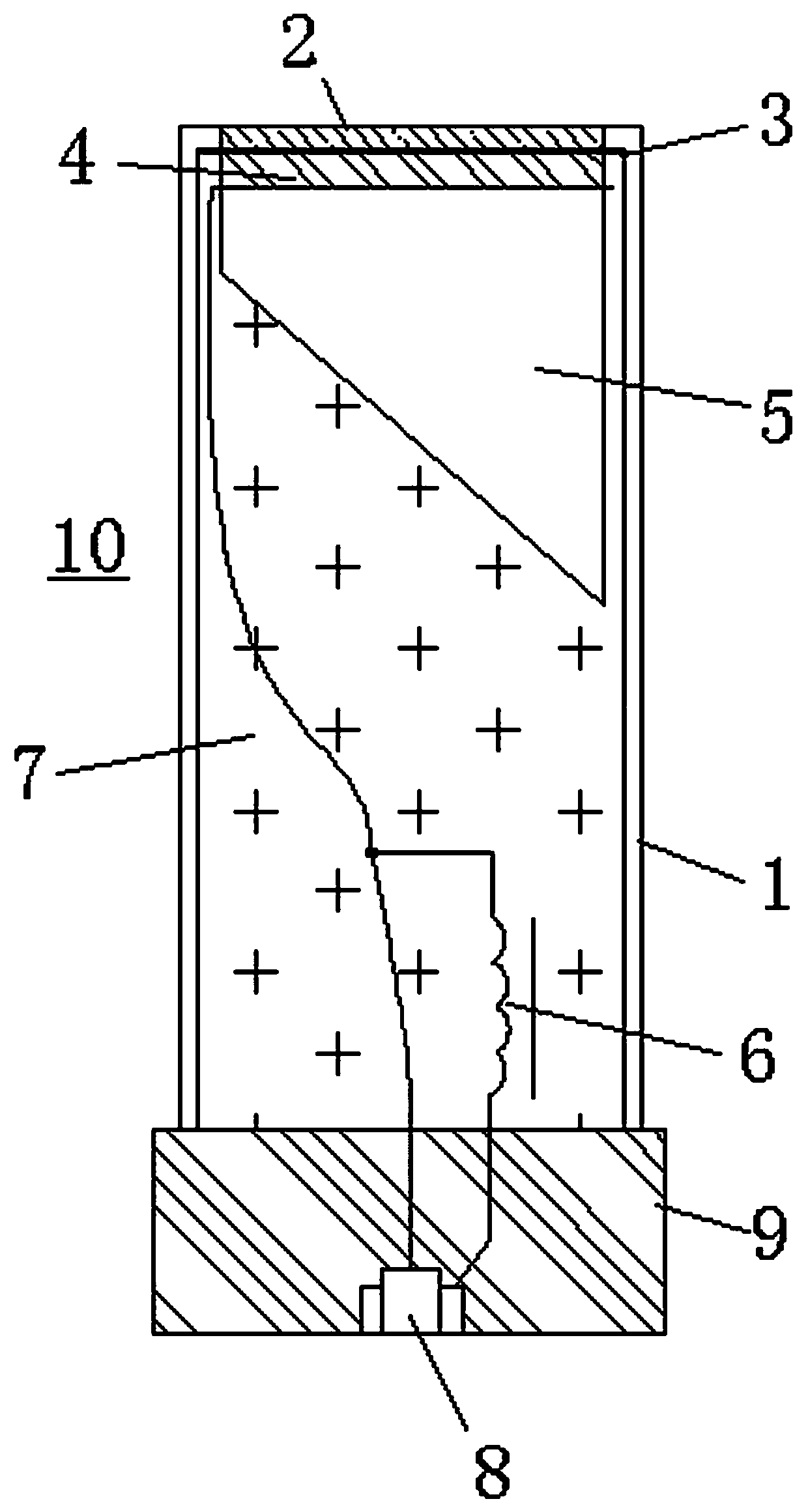

[0053] See attached figure 1 , the ultrasonic probe 10 includes a housing 1 and a front matching layer 2, a metal gasket 3, a piezoelectric wafer 4, an acoustic matching layer 5 and an electrical matching layer 6 arranged in sequence from front to back in the housing 1, and the front end of the metal gasket 3 is matched with the front The layer 2 is bonded, the rear end is bonded to the piezoelectric chip 4, the piezoelectric chip 4 is connected to the electrical matching 6 through a high-frequency wire, the acoustic matching layer 5 is arranged behind the piezoelectric chip 4, and the electrical matching 6 is an inductance element. The acoustic matching layer and electrical ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com