Coil assembly of current transformer and production process thereof

A technology of current transformer and coil, applied in the direction of transformer/inductor coil/winding/connection, inductor, transformer/inductor magnetic core, etc., can solve the problem of unreasonable structural design of coil assembly, low qualification rate and production efficiency It can improve the light load error curve, increase the number of coil ampere turns, and achieve stable and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

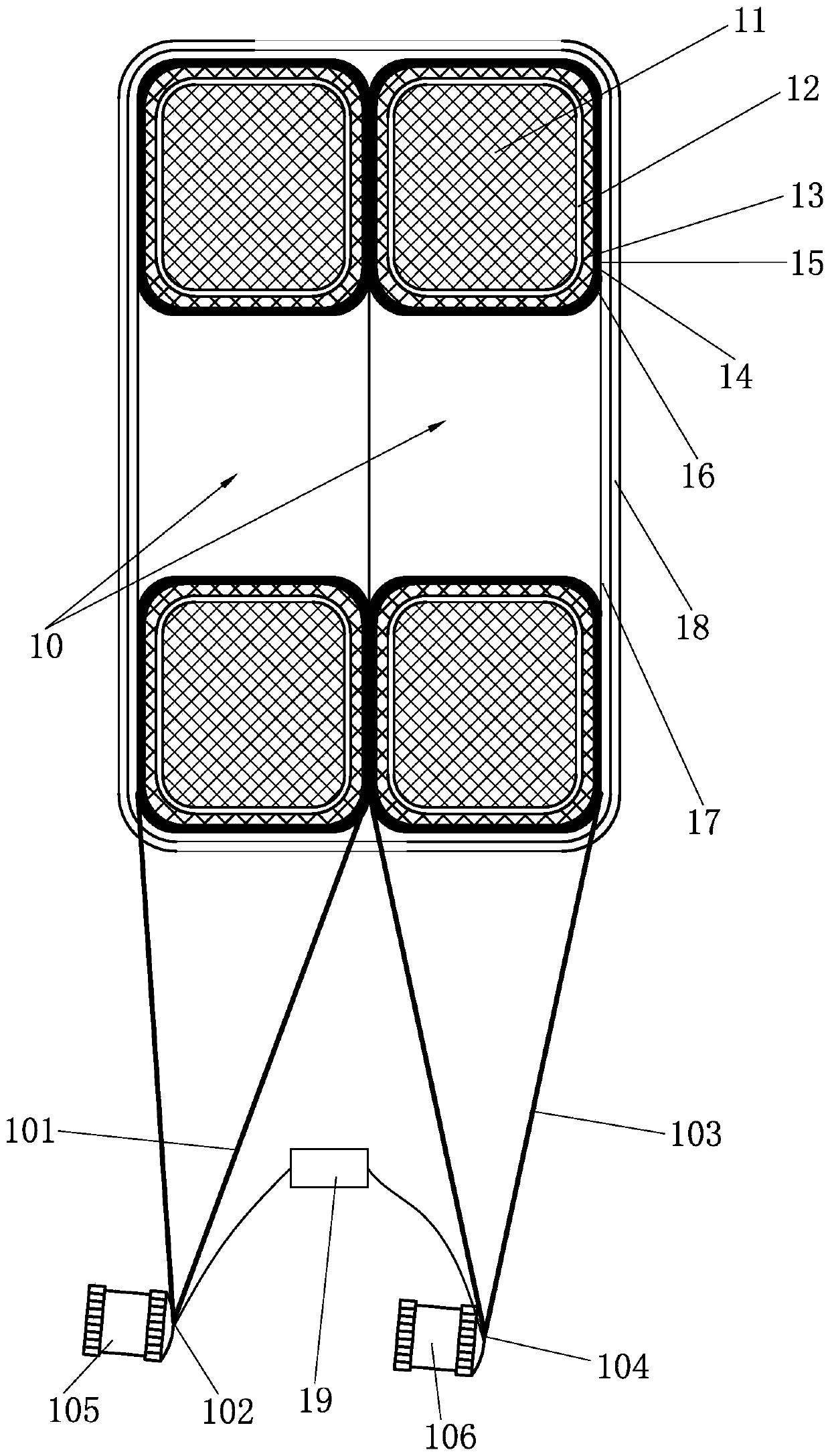

[0017] Such as figure 1 As shown, the embodiment of the present invention is a coil assembly of a current transformer, including two superimposed coil windings 10, and the coil winding 10 includes a main annular iron core 11 wrapped on the main annular iron core 11 The first insulating layer 12, the coil 13 wound on the first insulating layer 12, the compensation ring core 14 arranged inside the coil 13, the second insulation layer 15 wrapped on the compensation ring core 14, wrapped in the coil The third insulating layer 16 on 13, the two coil windings 10 are wrapped with a sponge layer 17, the sponge layer 17 is wrapped with a fourth insulating layer 18, the incoming wires of the two coil windings 10 The lead wires 101 are connected and form an incoming wire end 102. The outgoing wire leads 103 of the two coil windings 10 are connected and form an outgoing wire end 104. The incoming wire end 102 and the outgoing wire end 104 pass through the sponge layer in turn. 17. The fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com