A device power supply protection circuit and control method

A technology of power protection and relay control, applied in the field of electronics, can solve the problems of high development cost and high maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiments of the present application provide a device power supply protection circuit and a control method, which are used to provide grid undervoltage protection and power supply delay protection against voltage shocks.

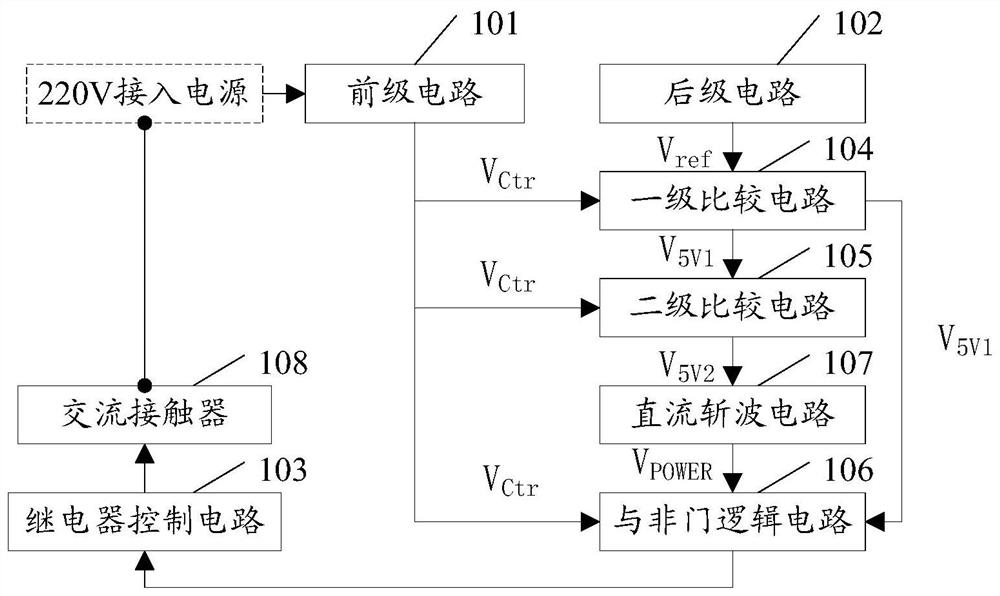

[0056] see figure 1 , the equipment power supply protection circuit mainly includes the following modules:

[0057] Pre-stage circuit 101, post-stage circuit 102, relay control circuit 103, primary comparison circuit 104, secondary comparison circuit 105, and NAND logic circuit 106;

[0058] The pre-stage circuit 101 is used to process the incoming power supply and generate a comparison voltage V Ctr The access power supply is the access power supply of the protected equipment; the front-stage circuit includes: a step-down module, a rectification module, a voltage stabilization module and a voltage divider module; the access power supply is rectified by the step-down module After being processed by the module and the voltage stabilizing module, a ...

Embodiment 2

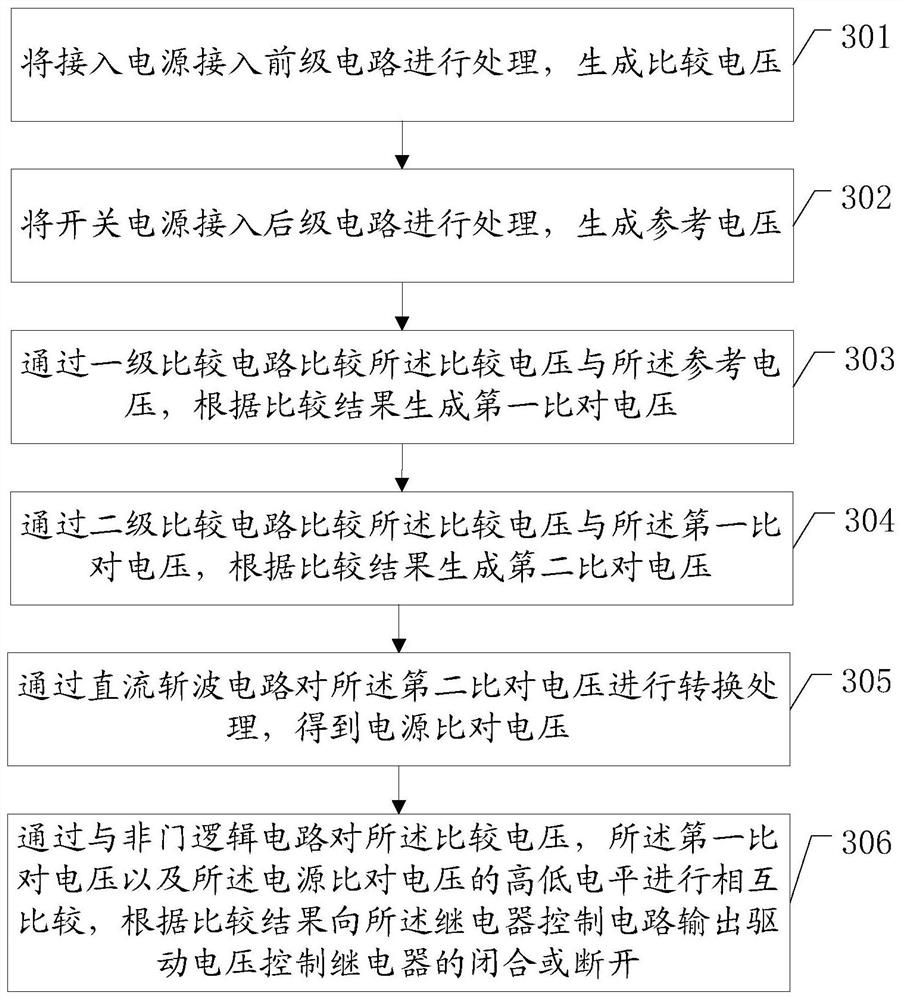

[0077] For ease of understanding, the embodiment of this application provides an application example of the device power supply protection circuit, please refer to figure 2 , figure 2 An application electrical diagram for the equipment power protection circuit, including:

[0078] exist figure 2 In the circuit shown, the pre-stage circuit, the post-stage circuit and the relay control circuit are connected through the interface in the power protection board in the figure. Among them, the J1 port is the input terminal of 220V AC in the pre-stage circuit, and the J3 port is the post-stage circuit. The input terminal of the 24V switching power supply, the J2 port is the output terminal of the relay, the closing and opening of the relay controls the on-off of the power supply of the equipment.

[0079] As shown in the figure, in the pre-stage circuit, a leakage protection circuit breaker and circuit breaker accessories are provided for leakage protection of the circuit. After t...

Embodiment 3

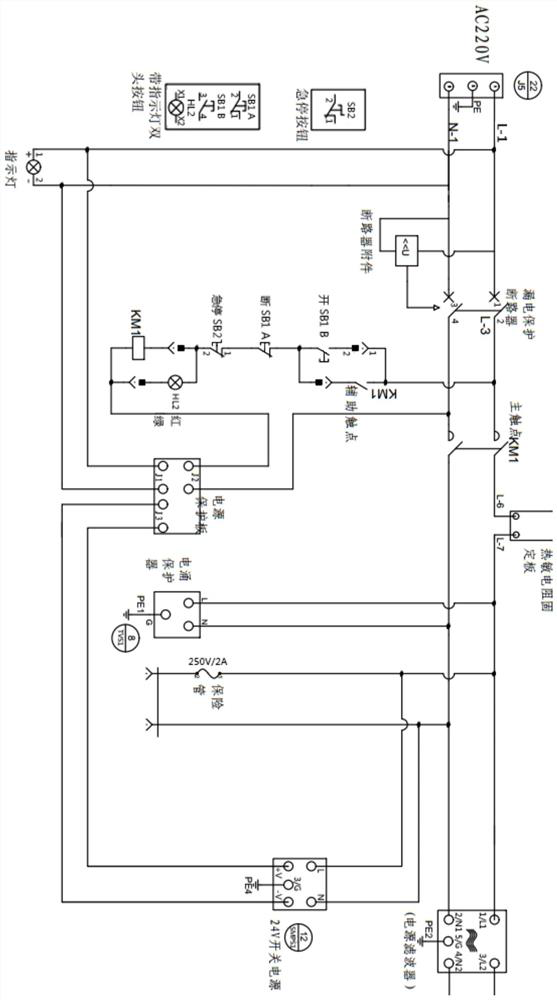

[0084] see image 3 , the control method corresponding to the device power supply protection circuit in the embodiment of the present application, including:

[0085] 301. Connect the incoming power to the pre-stage circuit for processing to generate a comparison voltage;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com