Lamination type oxygen generator

An oxygen generator and generator technology, which is applied in the fields of oxygen preparation, oxygen/ozone/oxide/hydroxide, chemical instruments and methods, etc. The column is too high and too long, the scope of application is wide, and the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

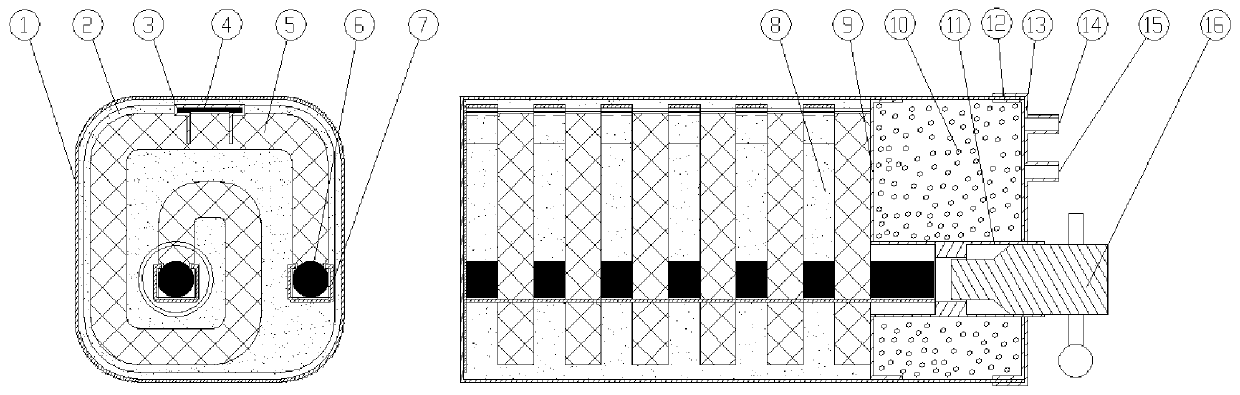

[0040] figure 1 is a cross-sectional view of a generator in two directions, showing an embodiment of a stacked oxygen generator according to the present invention. As shown in the figure, the oxygen generator includes a generator housing 1 and a generator upper cover 13, wherein the generator housing 1 is in the shape of a rectangular cylinder with rounded corners, the bottom is closed, the upper opening is open, and the inner part of the chamber is used as a combustion chamber. chamber and filled with oxygen tablets 5 and heat insulating material 8; the upper cover 13 of the generator is provided with three circular holes, which are respectively used to install the ignition device, the pressure relief valve 14 and the flow regulating valve of the gas outlet 15, and the upper cover 13 of the generator is welded on the generator housing 1. The ignition device is connected with the generator upper cover 13 by welding.

[0041]The oxygen generator also includes an ignition devi...

Embodiment 2

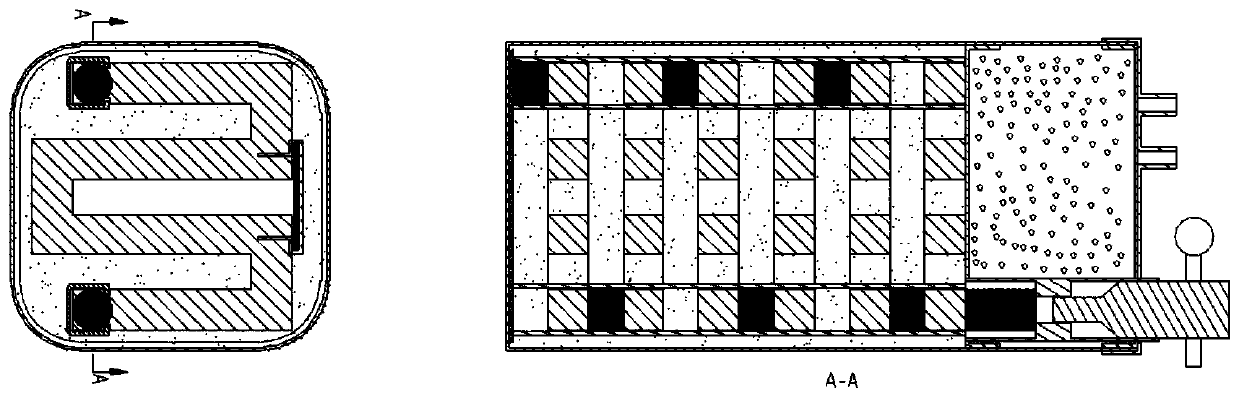

[0056] figure 2 It represents an embodiment of a laminated solid oxygen generator. In this embodiment, the oxygen tablet is an M-shaped flat structure folded from one end to the other end. In the solid oxygen generator made in the above manner, the trigger signal first triggers the igniter, and then ignites the connected grain by the igniter. Sequential, continuous low-flow combustion realizes long-term low-flow oxygen supply, and the generated oxygen is purified and cooled by the filter layer to obtain low-temperature, pure oxygen, which is discharged through the outlet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com