Luminescent cement mortar and preparation method thereof as well as luminescent concrete and preparation method of luminescent concrete

A technology of luminous cement and concrete, which is applied in the field of luminous concrete and its preparation, luminous cement mortar and its preparation, and can solve the problem that light cannot penetrate the surface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

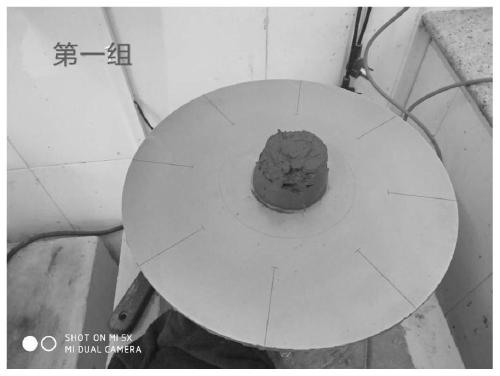

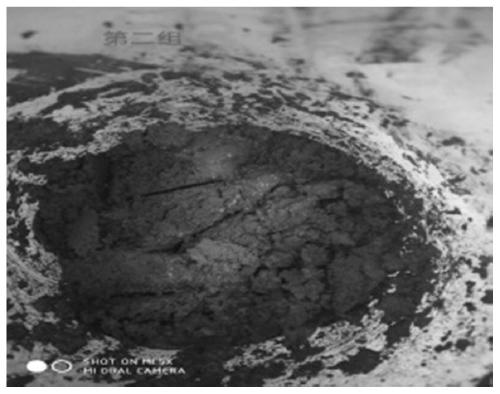

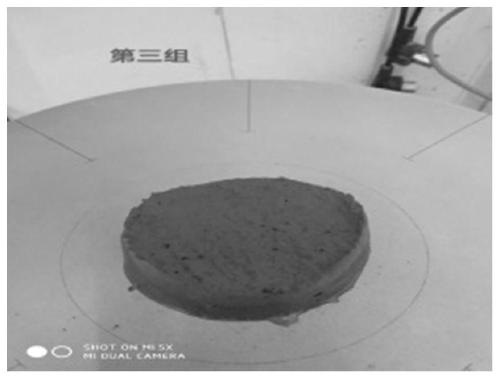

Image

Examples

preparation example Construction

[0051] The preparation method of the above-mentioned luminous cement mortar comprises the following steps:

[0052] In terms of parts by mass, take 0.8-1.2 parts of cement, 0.8-1.2 parts of luminescent channel materials, 0.0001-0.0005 parts of cellulose ether, 0.01-0.04 parts of redispersible latex powder, 0.023-0.028 parts of long-lasting luminescent materials, 0.01- 0.018 parts of water reducer and 0.3-0.40 parts of water.

[0053] Mix cement, cellulose ether, redispersible latex powder, and long-lasting luminescent material into a mixed powder after dry mixing;

[0054] Mix water reducer and water to form a mixed liquid;

[0055] Pour the mixed powder into the mixed liquid, and after stirring, it is called luminous cement paste;

[0056] Put the luminous channel material into the luminous cement slurry during the mixing process, and then continue to stir to form the luminous water mortar;

[0057] After putting in, continue to stir into luminous cement mortar;

[0058] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com