Modified polypropylene master batch and preparing method thereof

A polypropylene and master batch technology, applied in the field of modified polypropylene master batch and its preparation, can solve the problems of small elastic modulus and poor breaking properties, and achieve the effects of high elastic modulus, easy breaking and easy forming and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

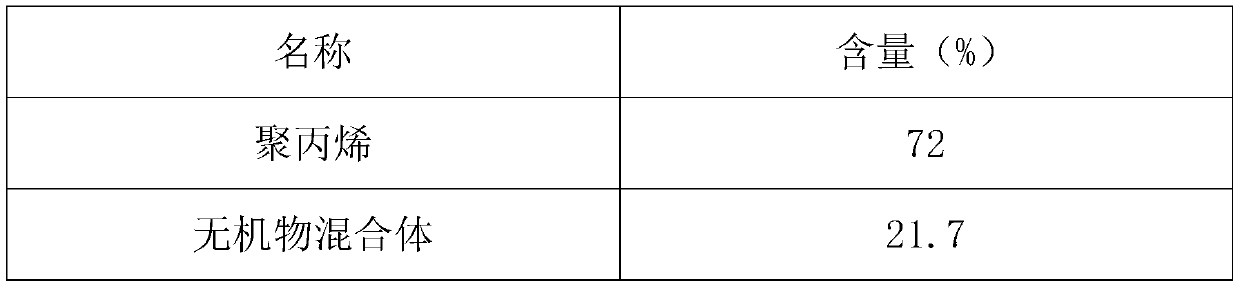

[0030] The invention discloses a modified polypropylene masterbatch, which is composed of the following raw materials according to weight percentage:

[0031] Inorganic mixture 62%, polypropylene 20%, special resin A6%, special resin B5%, PE wax 3%, dispersant 3.5% and stiffening agent 0.5%.

[0032] The invention also discloses a preparation method of a modified polypropylene masterbatch, comprising the following steps:

[0033] Step 1. Add calcium carbonate, talcum powder, titanium dioxide and precipitated Bas04 into a high-speed mixer, mix and surface treat at 100°C-120°C to obtain an inorganic compound;

[0034] Step 2: Add PE wax, dispersant and stiffening agent into a high-speed mixer, and mix and surface-treat with the inorganic mixture prepared in step 1 under the condition of 100°C-120°C to obtain a middle-stage mixture;

[0035] Step 3, adding polypropylene, special resin A and special resin B to a high-speed mixer, and mixing with the intermediate mixture prepared ...

Embodiment 2

[0049] The invention discloses a modified polypropylene masterbatch, which is composed of the following raw materials according to weight percentage:

[0050] Inorganic mixture 61%, polypropylene 18%, special resin A 8%, special resin B 6%, PE wax 4%, dispersant 2.4% and stiffening agent 0.6%.

[0051] The invention also discloses a preparation method of a modified polypropylene masterbatch, comprising the following steps:

[0052] Step 1. Add calcium carbonate, talcum powder, titanium dioxide and precipitated Bas04 into a high-speed mixer, mix and surface treat at 100°C-120°C to obtain an inorganic compound;

[0053] Step 2: Add PE wax, dispersant and stiffening agent into a high-speed mixer, and mix and surface-treat with the inorganic mixture prepared in step 1 under the condition of 100°C-120°C to obtain a middle-stage mixture;

[0054] Step 3, adding polypropylene, special resin A and special resin B to a high-speed mixer, and mixing with the intermediate mixture prepare...

Embodiment 3

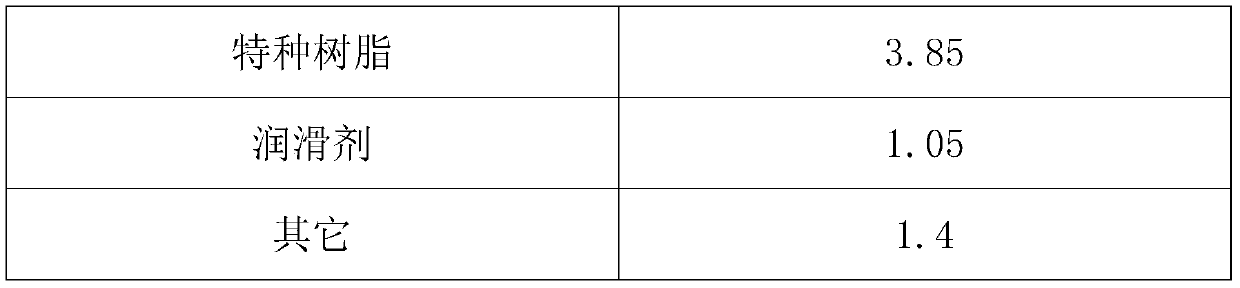

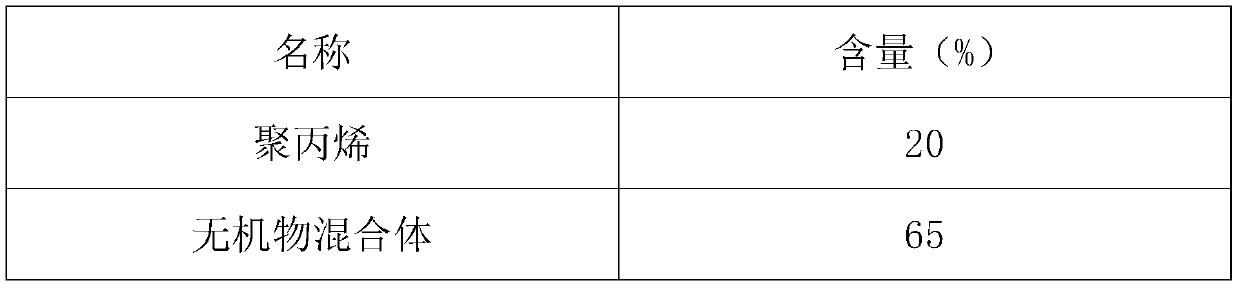

[0067] The invention discloses a modified polypropylene masterbatch, which is composed of the following raw materials according to weight percentage:

[0068] Inorganic mixture 65%, polypropylene 20%, special resin A5%, special resin B4%, PE wax 2%, dispersant 3.4% and stiffening agent 0.6%.

[0069] The invention also discloses a preparation method of a modified polypropylene masterbatch, comprising the following steps:

[0070] Step 1. Add calcium carbonate, talcum powder, titanium dioxide and precipitated Bas04 into a high-speed mixer, mix and surface treat at 100°C-120°C to obtain an inorganic compound;

[0071] Step 2: Add PE wax, dispersant and stiffening agent into a high-speed mixer, and mix and surface-treat with the inorganic mixture prepared in step 1 under the condition of 100°C-120°C to obtain a middle-stage mixture;

[0072] Step 3, adding polypropylene, special resin A and special resin B to a high-speed mixer, and mixing with the intermediate mixture prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com