High temperature fermentation machine

A technology for high-temperature fermentation and fermented products, which is applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc. Complete and other problems, to avoid poor contact, uniform heating, and not easy to burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

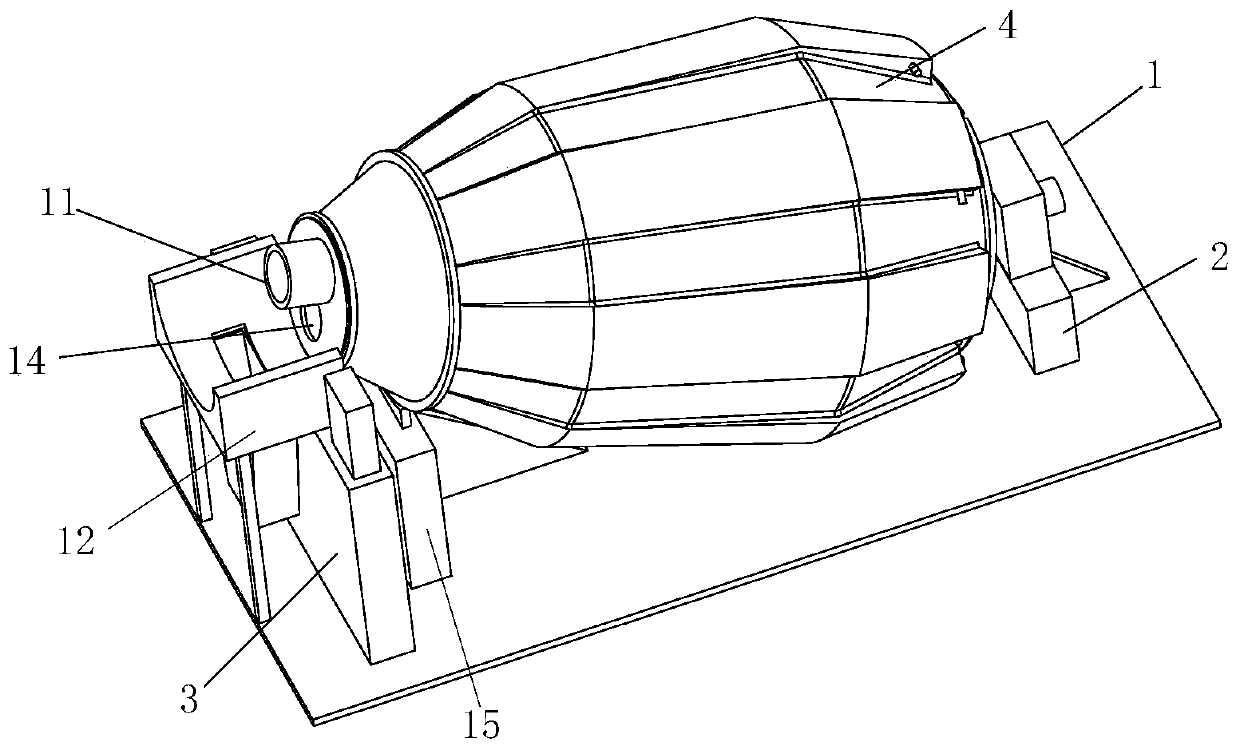

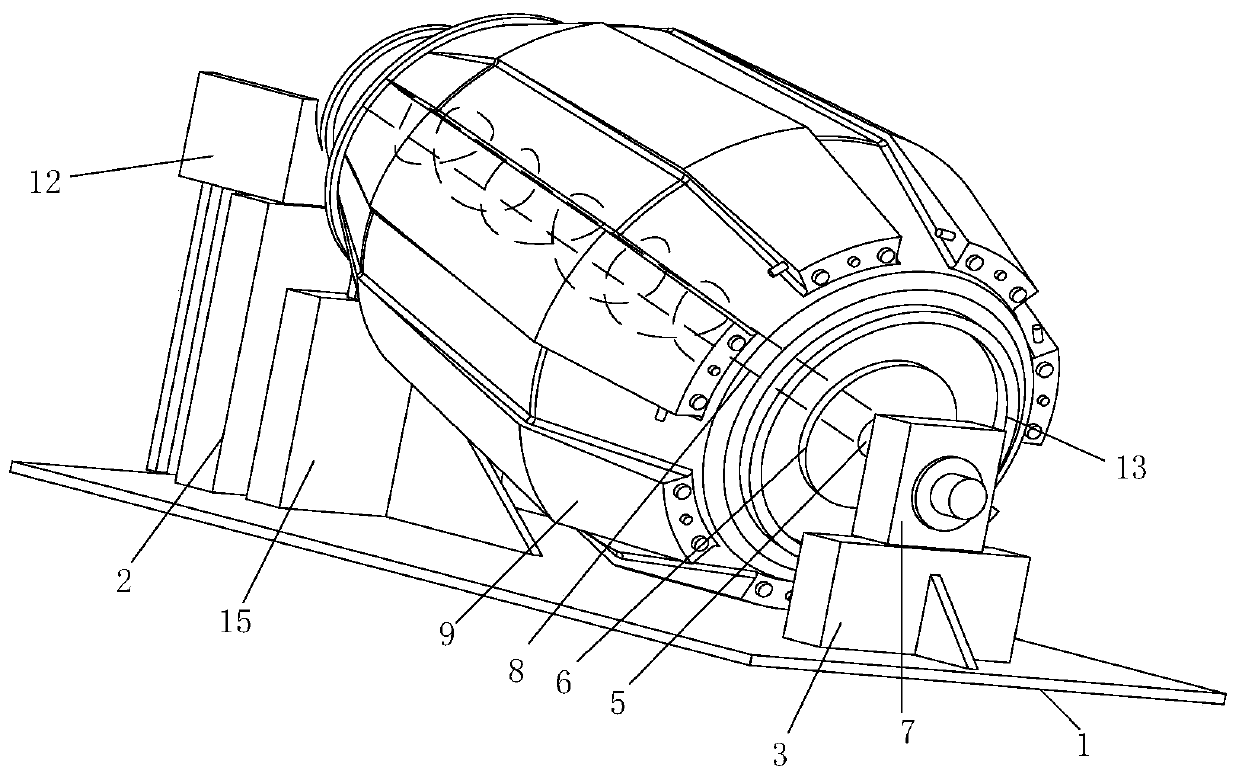

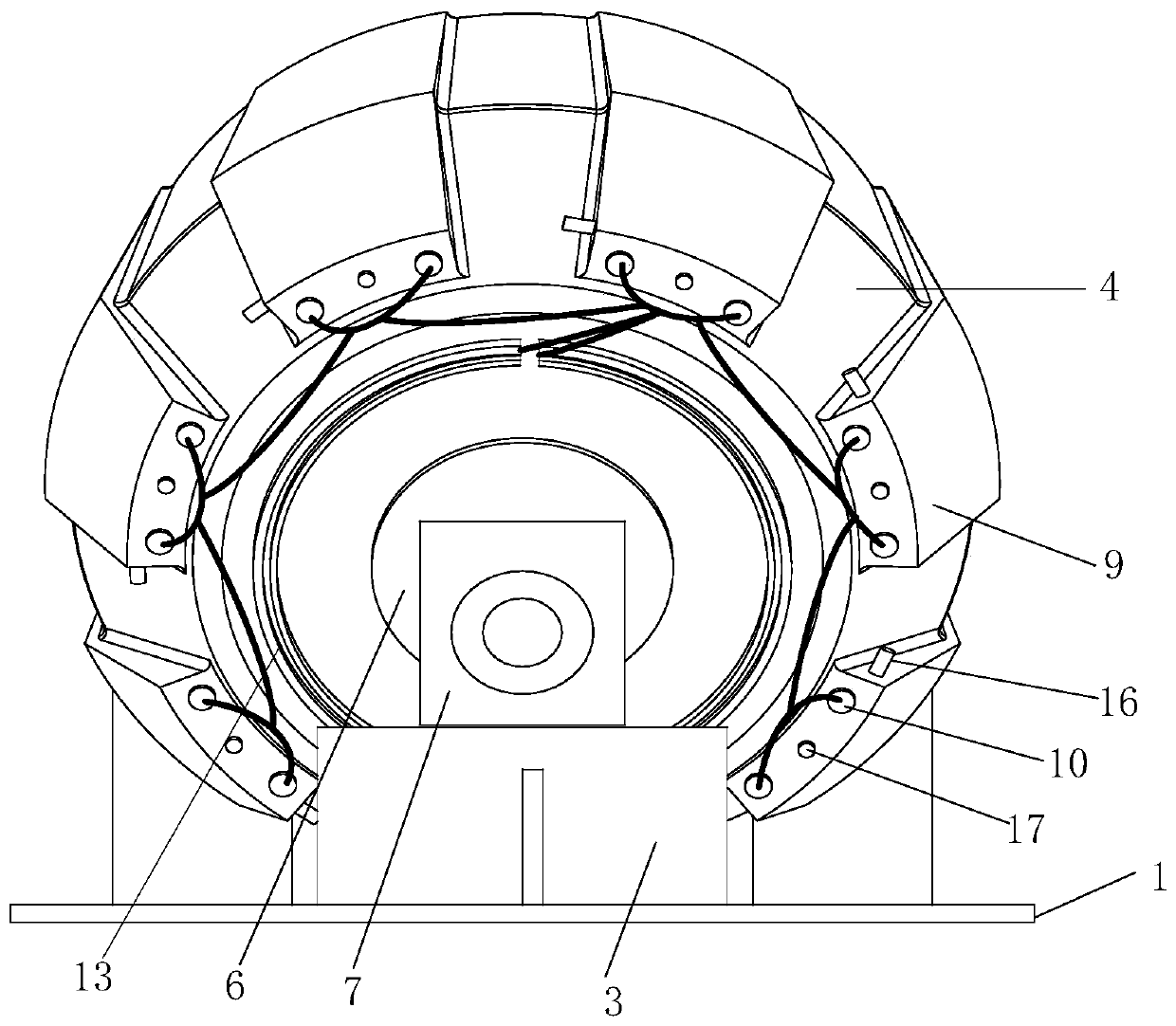

[0054] Such as Figure 1 to Figure 5 As shown, the invention provides a kind of high-temperature fermenter, comprising:

[0055] The bottom plate 1, the two ends of the bottom plate 1 are respectively provided with a first bracket 2 and a second bracket 3, and the first bracket 2 is higher than the second bracket 3;

[0056] Barrel 4, one end of barrel 4 is rotatably connected to the first support 2, and the other end of barrel 4 is rotatably connected to second support 3; one end of barrel 4 is provided with a feed port 11 and a discharge port 14;

[0057] Stirring device, located in the barrel body 4, for stirring the fermented product;

[0058] The heating device is arranged on the side wall of the barrel body 4, and is used to heat the fermented product in the barrel body 4;

[0059] The driving device is connected to the other end of the barrel body 4 and is used to drive the barrel body 4 and the stirring device to rotate respectively.

[0060] In this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com