Adhesive sticker wall poster manufacturing method

A manufacturing method and adhesive wall technology, which is applied in papermaking, special paper, adhesives, etc., can solve the problems of reducing work efficiency, increasing labor costs, and being unable to automatically organize, etc., and achieve the effect of convenient implementation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

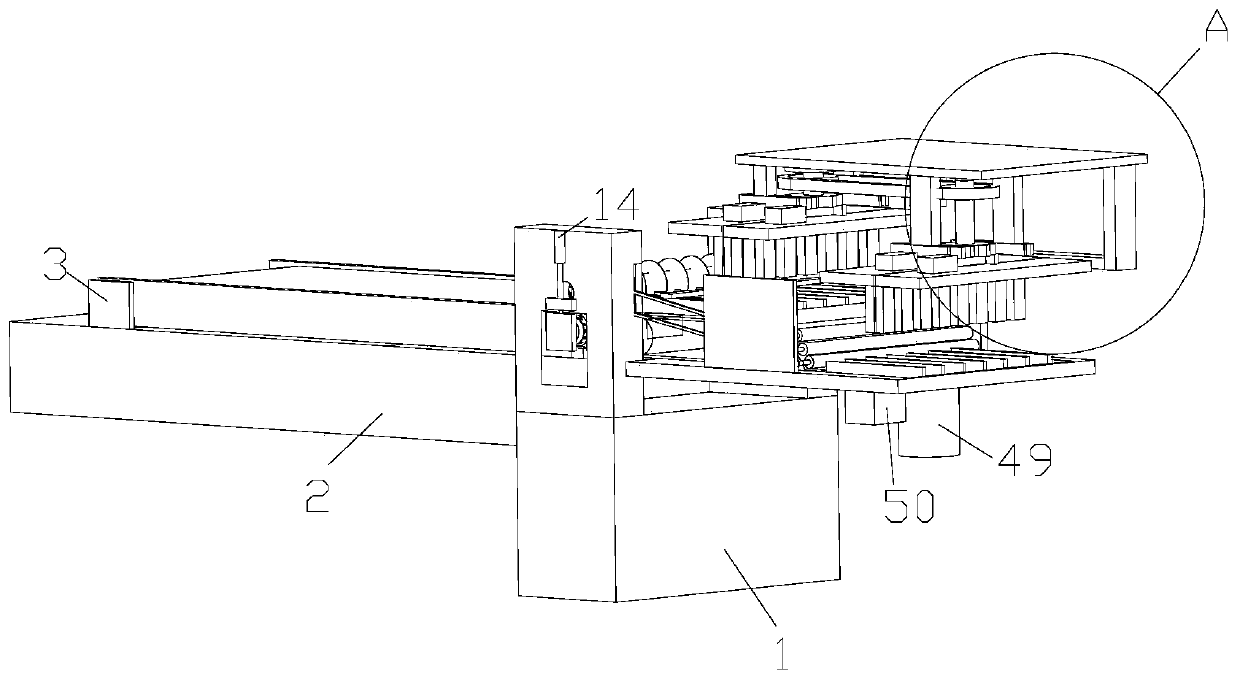

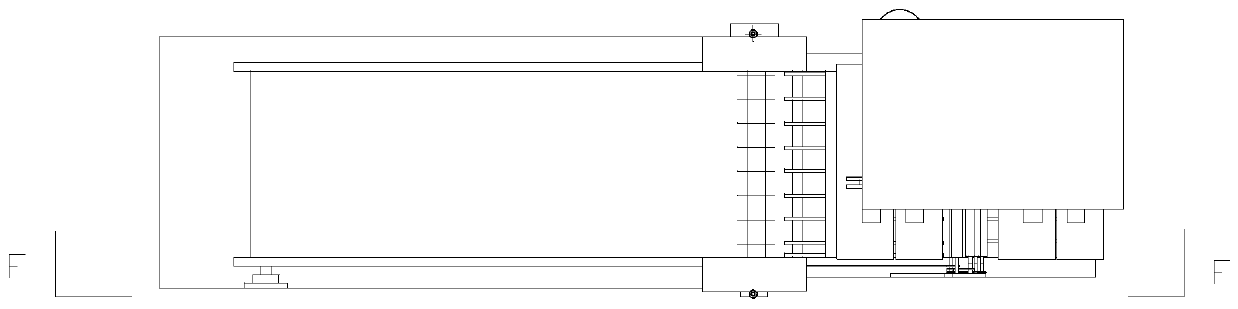

[0035] A method for manufacturing self-adhesive wall stickers, the steps of the processing method can be divided into,

[0036] a. Unwinding, through the unwinding equipment, the self-adhesive wall sticker base paper rolled into a roll is unfolded and transported to the next process smoothly;

[0037] b. Printing, printing the pattern or text on the base paper of the self-adhesive wall sticker through the printing machine and using the printing plate as a template;

[0038] c. Glazing, apply a layer of varnish on the self-adhesive wall sticker base paper;

[0039] d. Bronzing;

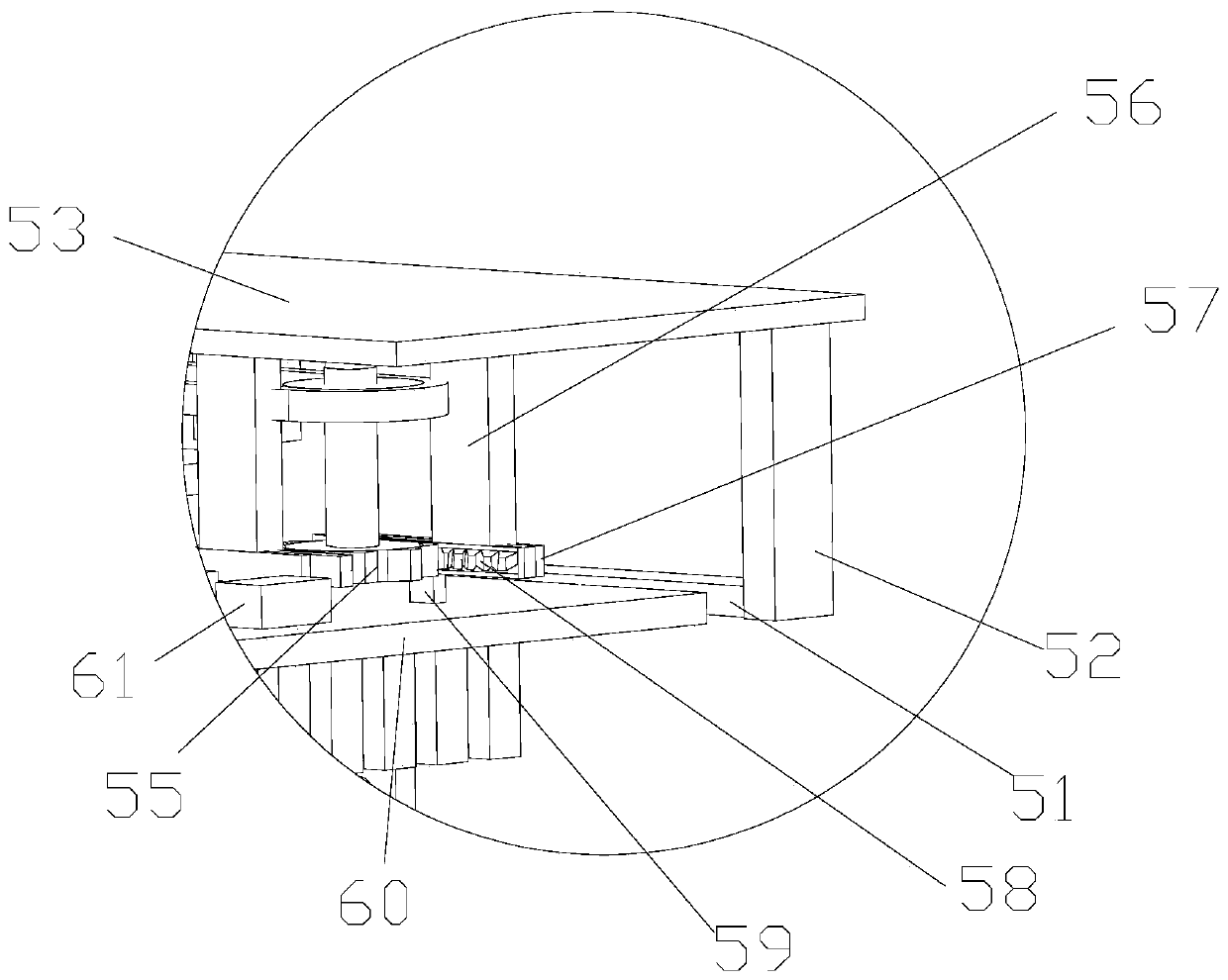

[0040] e. Die cutting, cutting the continuous self-adhesive label base paper into semi-finished products of predetermined length through a cutting machine.

[0041] f. Cut into strips, use the self-adhesive strip cutter to cut the cut semi-finished products into strips.

[0042] The material of the wall sticker base paper includes pulp, modified wood powder, polyvinyl alcohol, nano-alumina, bleachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com