Burner single piece, burner and gas hot water equipment

A gas-fired hot water and burner technology, used in burners, gas fuel burners, lighting and heating equipment, etc., can solve the problems of large resistance loss, high noise, and high labor costs, reduce flow resistance loss, reduce heat Intensity and noise, uniform effect of outlet pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

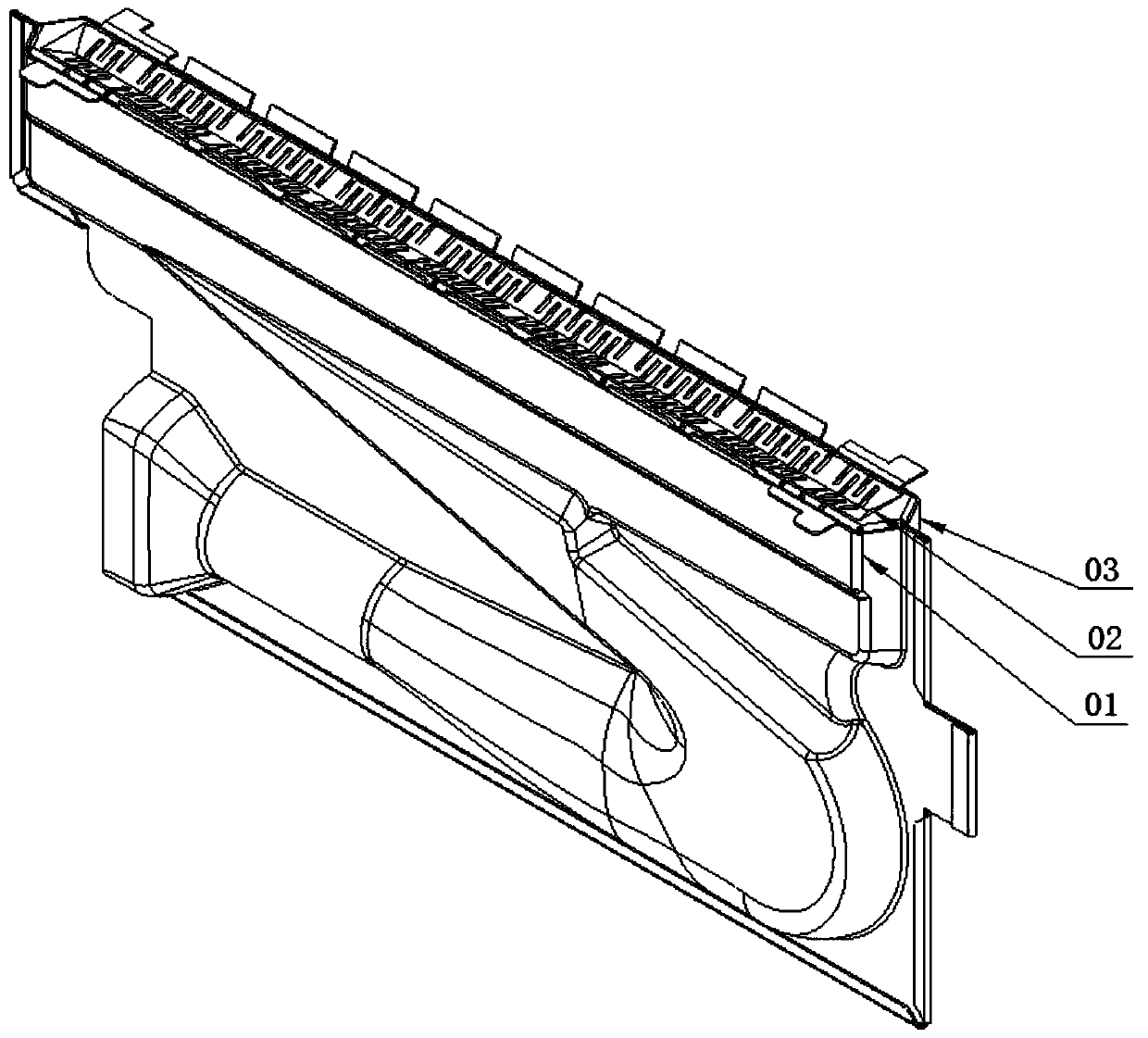

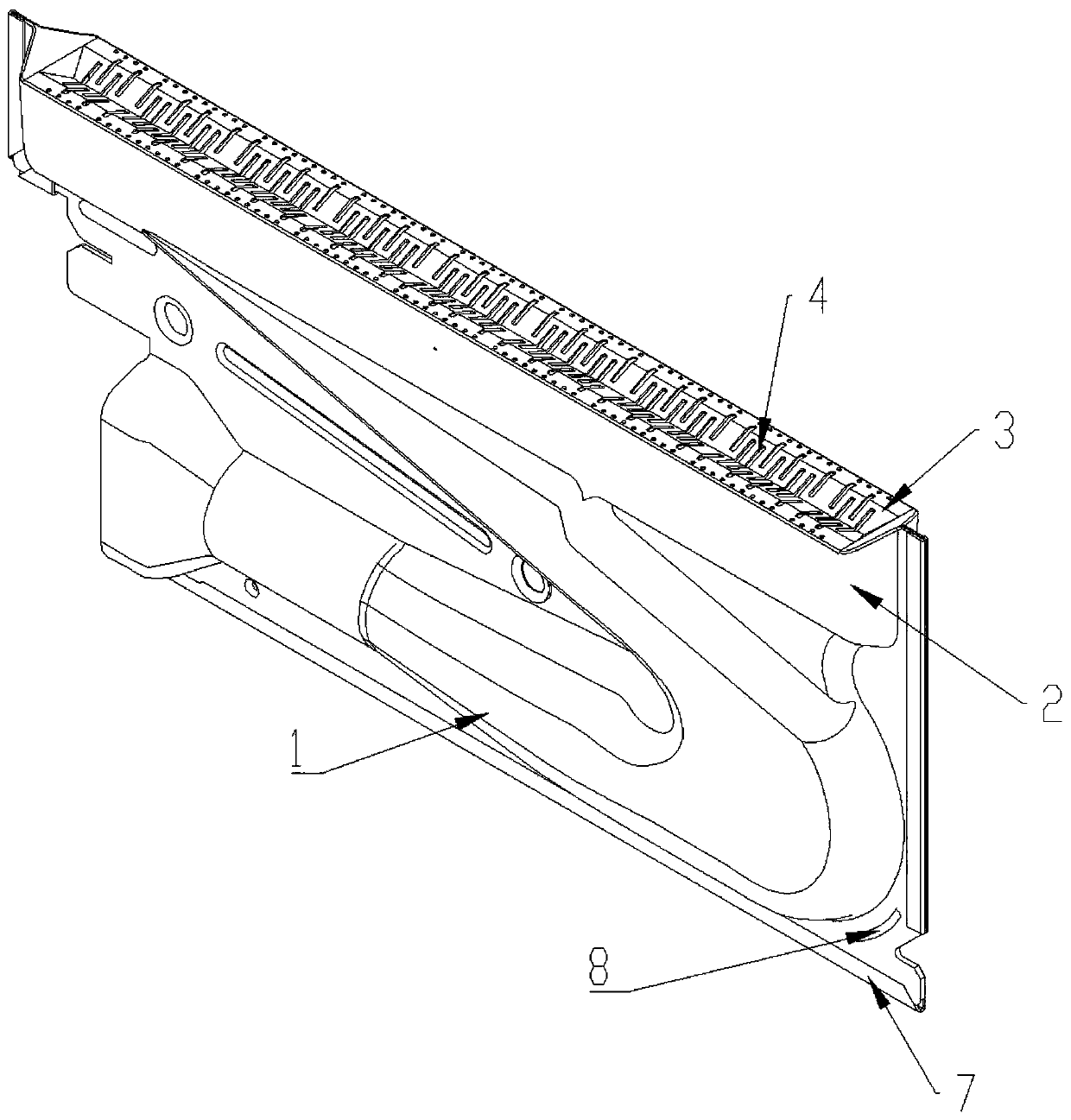

[0037] like Figure 3-Figure 7 As shown, a single piece of burner includes a fire row shell 2 with an ejector tube 1, an upper opening, and a combustion plate 3 arranged on the upper opening, and a strip-shaped fire hole is arranged on the combustion plate 3 4. It is characterized in that at least one row of circular auxiliary fire holes 5 are respectively provided on both sides of the strip-shaped fire holes 4 .

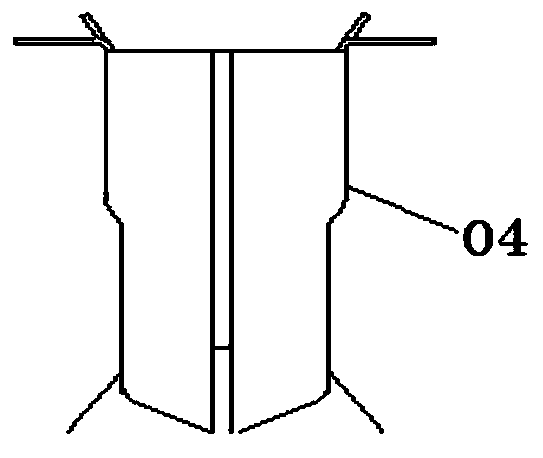

[0038] Wherein, the combustion plate 3 is an integrally formed structure, including a top plate 3-1 and two side plates 3-2 arranged along the length direction of the top plate, and the strip-shaped fire hole 4 and the auxiliary fire hole 5 are arranged on On the top board 3-1, the side boards 3-2 are inclined downward and narrowed inwardly. The width value of the top plate 3-1 is larger than the width value of the existing single-piece top plate 3-1 of the burner, and has different specific values according to different models, and its value range is 9-15mm. Th...

Embodiment 2

[0046] A burner, comprising a single burner, characterized in that the single burner is as described in Embodiment 1.

[0047] The burner provided in this embodiment has all the beneficial effects of the first embodiment. As for the specific structure of the burner, existing known or possible future burner schemes can be adopted, which will not be repeated here.

Embodiment 3

[0049] A gas-fired water heater, comprising a gas-fired water heater body and a burner arranged in the gas-fired water heater body, wherein the burner is as described in Embodiment 2.

[0050] Wherein, the gas hot water equipment is a gas water heater or a gas wall-hung boiler.

[0051] The gas water heating equipment provided in this embodiment has all the beneficial effects of the second embodiment. As for the specific structure of the gas water heater or the gas wall-hung boiler, existing known or future possible solutions can be adopted, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com