Method for measuring thickness of slag layer for fly ash fusion treatment

A technology of thickness measurement and slag layer, applied in the field of thickness measurement, can solve problems such as misreading, and achieve the effect of improving accuracy and reliable interpretation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

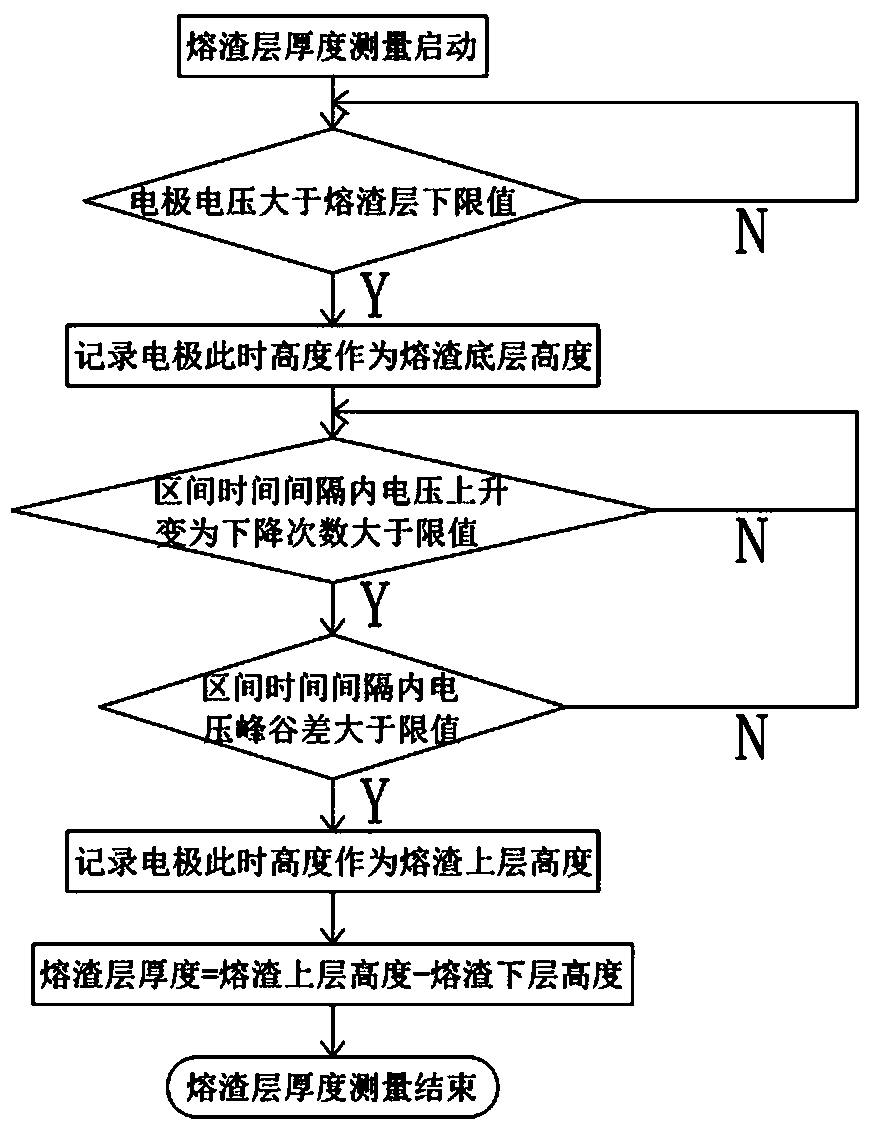

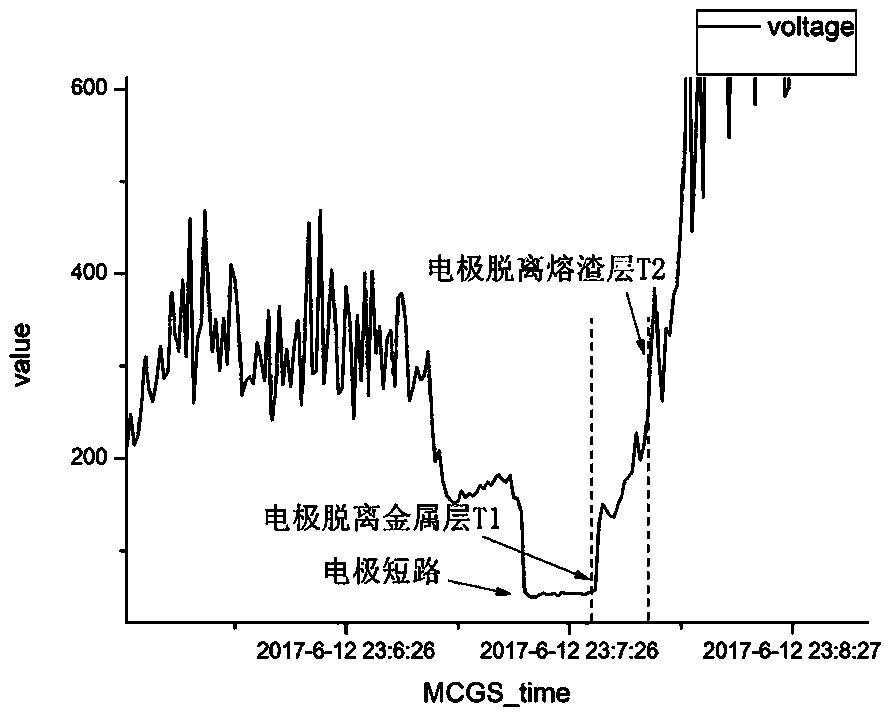

[0025] Such as figure 1 As shown, a method for measuring the thickness of a slag layer for fly ash melting treatment of the present invention comprises the following steps:

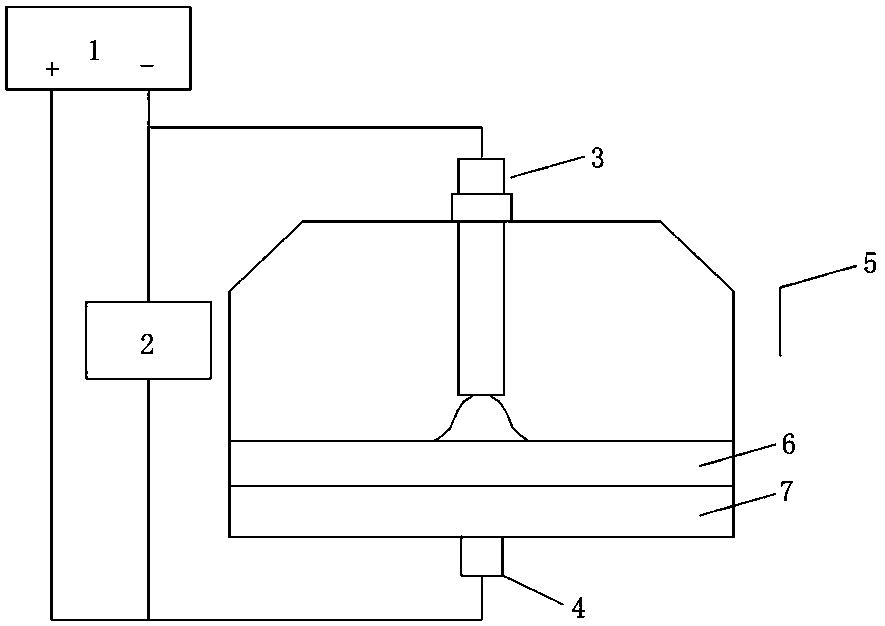

[0026] Step 1: Build an arc voltage measurement device; the arc voltage measurement device includes a DC power supply 1, a voltage measurement unit 2, a cathode electrode 3, an anode electrode 4, a furnace body 5, a slag layer 6 and a metal layer 7, and the upper end of the cathode electrode is connected to the DC power supply The lower end of the anode electrode is connected to the positive electrode of the DC power supply, and the two ends of the voltage measurement unit are respectively connected to the upper end of the cathode electrode and the lower end of the anode electrode....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com