Evaporative emission test device and method for automobile parts

A technology for auto parts and evaporative emissions, applied in the field of passenger car evaporative pollutant measurement, can solve problems such as affecting airtightness and deformation of airtight interior walls, and achieve the effect of easy management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

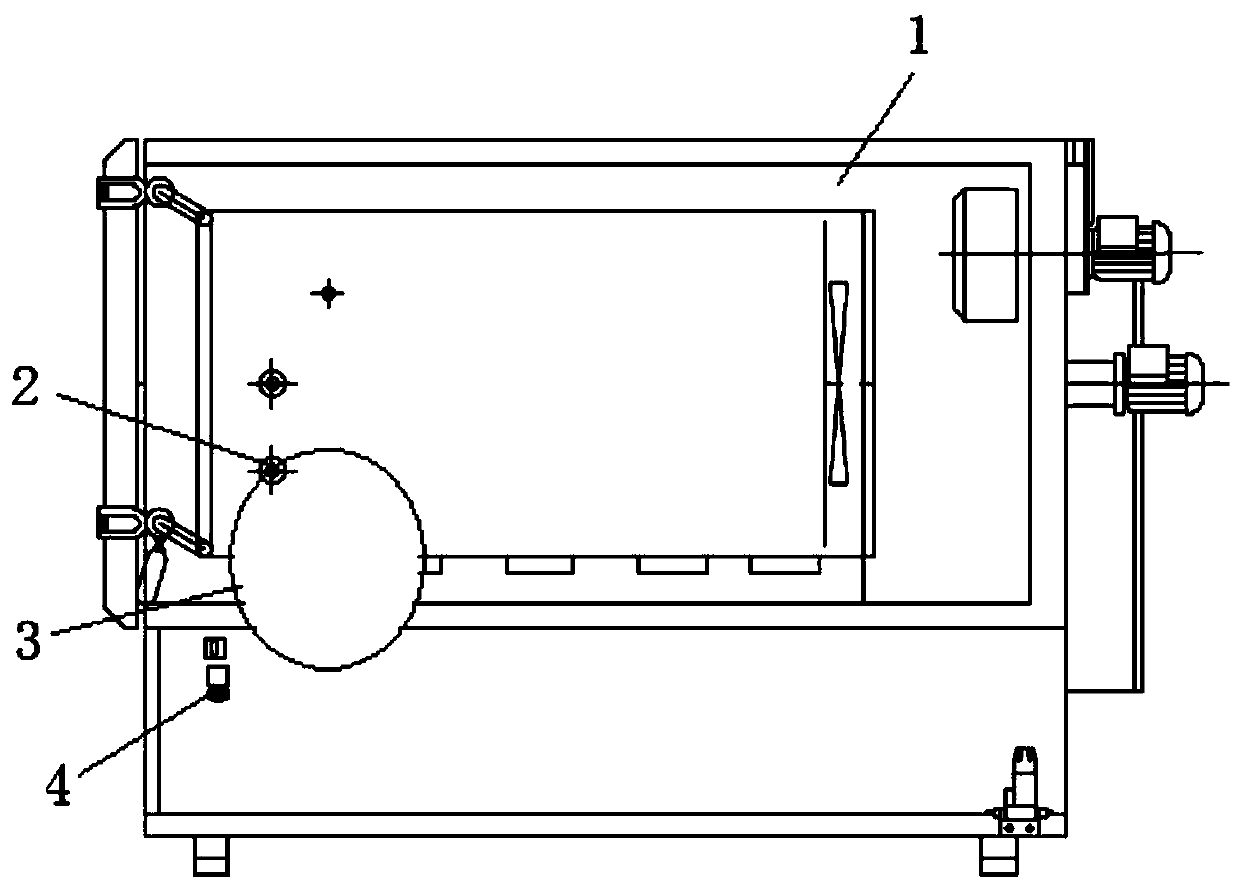

[0021] like figure 1 The evaporative emission test device of the auto parts shown includes a VOC environmental chamber 1 and a hydrogen flame ionization detector (FID). The bulkhead of the VOC environmental chamber 1 is provided with a hydrocarbon sampling port, and the hydrogen flame ionization detector The sampling tube is inserted into the hydrocarbon sampling port until it extends into the VOC environmental chamber 1 . An electromagnetic one-way valve 4 is connected to the exhaust pipe outside the cabin of the VOC environmental chamber 1. The operation mode of the equipment can be switched to the dynamic or static mode through the electromagnetic one-way valve 4. When the VOC test is performed, the electromagnetic one-way valve is opened to be the dynamic mode. , when conducting the evaporative emission experiment, close the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com