Eddy current retarder coil resistance test system and test method thereof

A technology of eddy current retarder and coil resistance, which is applied in the direction of measuring resistance/reactance/impedance, instruments, measuring devices, etc. It can solve problems such as resistance calibration and test results that cannot be automatically recorded, so as to improve consistency and improve product quality. Inspect the efficiency and solve the effect of the influence of the coil resistance measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further detailed below in conjunction with the accompanying drawings:

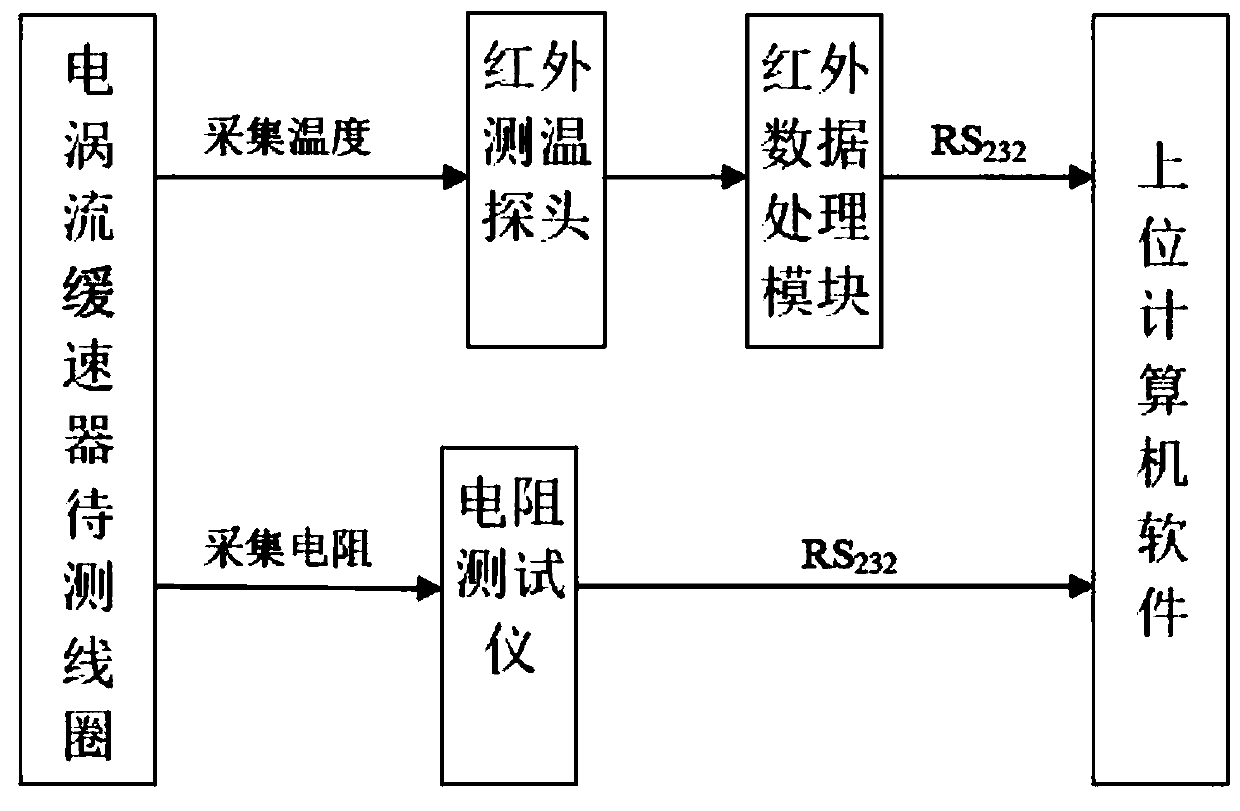

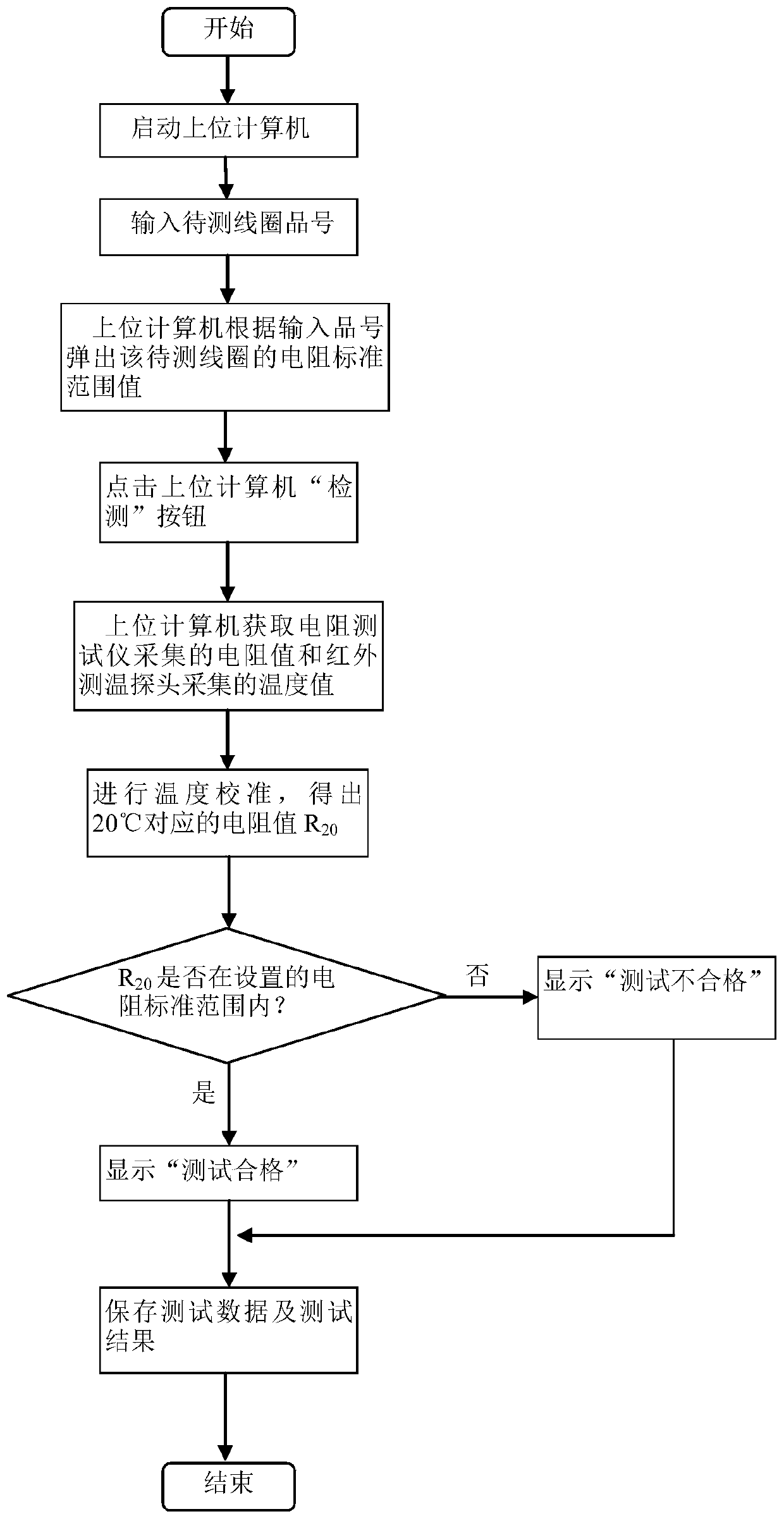

[0027] See figure 1 As shown, the eddy current retarder coil resistance test system includes a host computer, a resistance tester, an infrared temperature probe, an infrared data processing module, and a coil to be tested. The resistance tester measures the resistance value of the coil to be tested, and sends the measured resistance value through the serial port RS 232 Transmitted to the host computer; the infrared temperature probe senses the surface temperature of the coil to be measured through infrared rays, and the induced temperature signal is converted into temperature data by the infrared data processing module, and then passes through the serial port RS 232 Transfer to the host computer. The upper computer performs temperature calibration on the measured resistance value, and then compares and analyzes the resistance standard range value set, judges and displays th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com