A method of tool holder optimization based on ahp-gray relational analysis algorithm

A technology of gray relational analysis and tool fixtures, applied in the field of tool fixtures, can solve problems such as heavy workload, selection of tools, tool holders and fixtures, error-prone, etc., and achieve the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

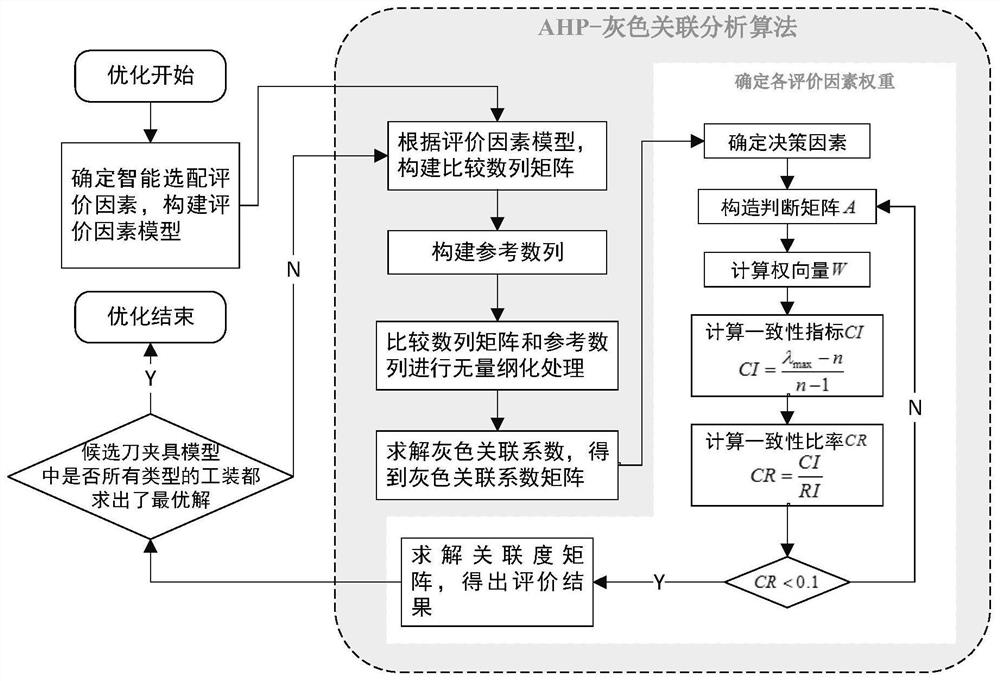

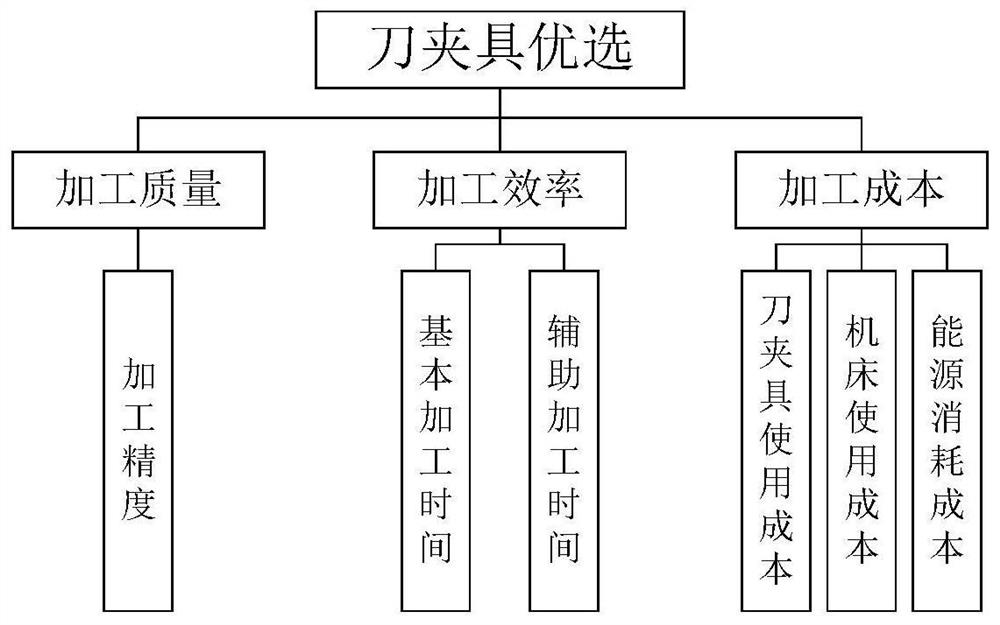

[0054] refer to figure 1 Shown, a kind of tool holder optimal method based on AHP-gray correlation analysis algorithm is characterized in that, comprises the following steps:

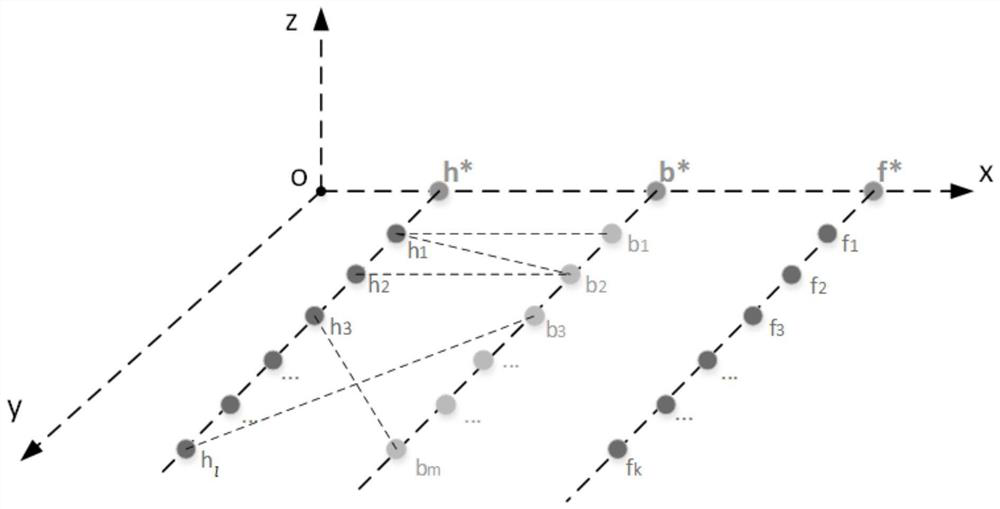

[0055] Step 1: Obtain the set of candidate tool holders T={H B F} that meets the processing task; where, H is the tool set, H={H 1 h 2 …H i …H l},H i Indicates the i-th tool type set in the tool set H; B is the tool holder set, B={B 1 B 2 …B i …B m}, B i Indicates the i-th type set of tool holders in the tool holder set B; F is the set of fixtures, F={F 1 f 2 …F i …F k}, F i Indicates the i-th fixture type set in the fixture set F.

[0056] Step 2: The tools, tool holders and fixtures are collectively referred to as tooling, and the optimal tooling corresponding to each tooling type in the tool set H, tool bar set B and fixture set F is respectively solved by using the AHP-gray correlation analysis algorithm; After optimizing each type of tooling in set H, tool bar set B and fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com