A product detection device for metal forming and its use method

A detection device, metal forming technology, applied in the direction of measuring device, mechanical measuring device, mechanical device, etc., can solve the problems that affect the quality and efficiency of detection, the flange block, the upper sleeve and the lower sleeve cannot be fixed and moved, etc., to achieve Multi-angle detection improves the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

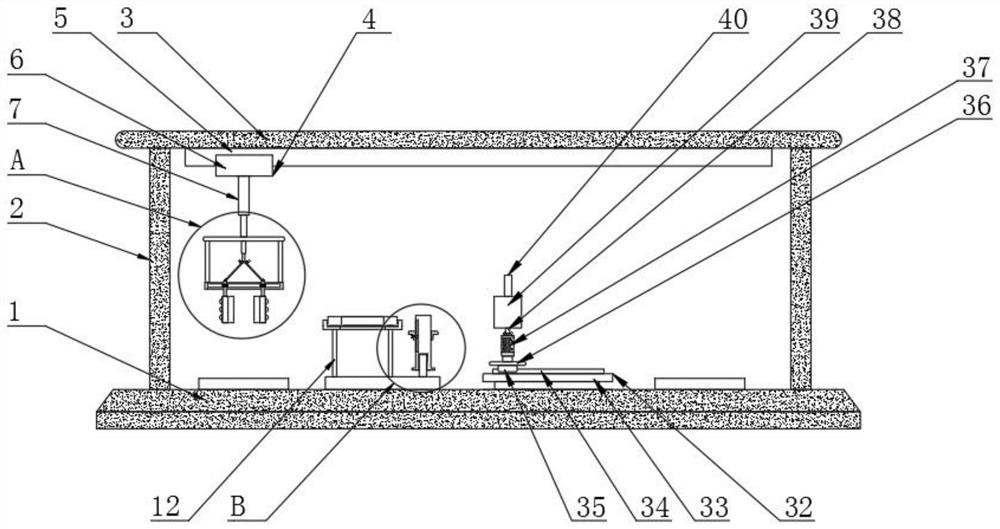

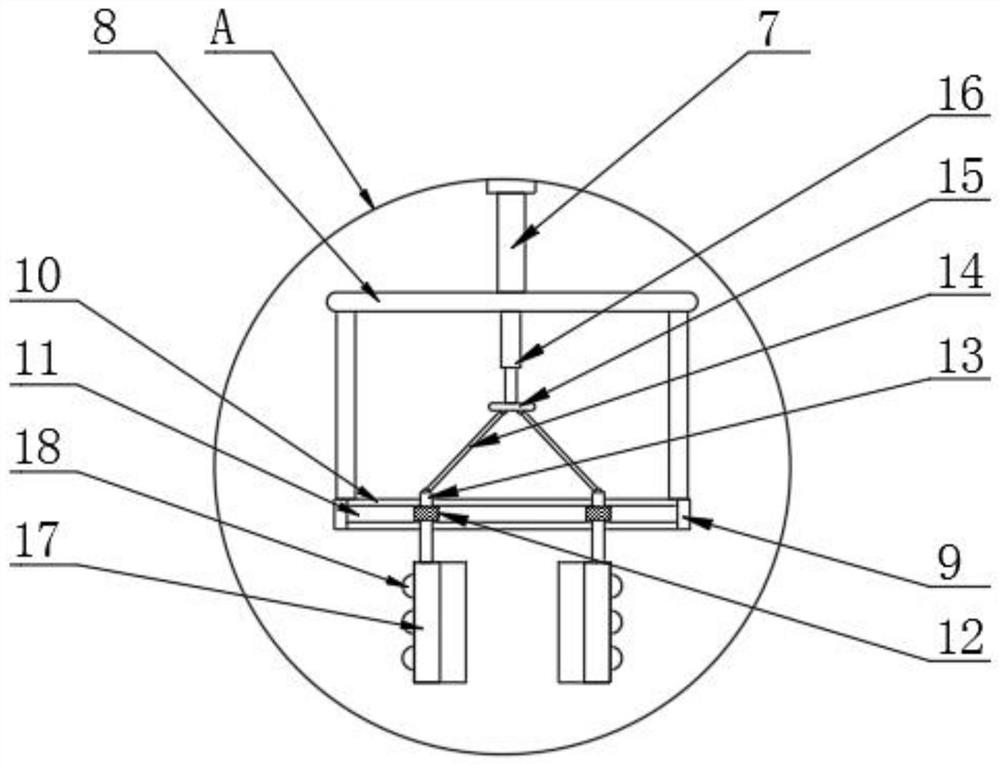

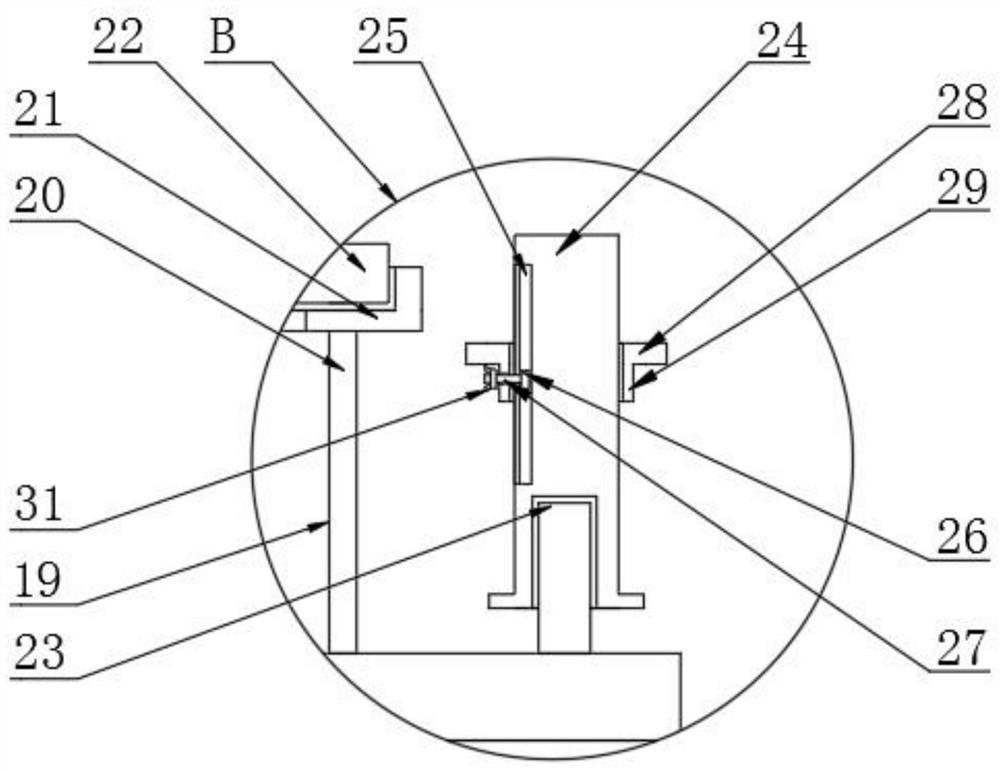

[0036] The specific embodiment is as follows: the flange block, the upper sleeve and the lower sleeve are placed on the placing plate 36, the electric telescopic rod 16 is opened, and the electric telescopic rod 16 drives the top rod 13 to move horizontally through the two push rods 14, and the top rod 13 drives the horizontal movement. The sliding block 12 slides inside the chute 11, and the balls provided increase the sliding speed of the sliding block 12. Then, the two sliding blocks 12 drive the two clamping rings 17 to move relatively or in opposite directions through the bottom rod, and then the hydraulic rod 7 is opened. Drive the positioning plate 9 to move up and down. When clamping the flange block, the distance between the two clamping rings 17 can be enlarged, and then the two clamping rings 17 clamp the flange block inside. After the distance between the upper sleeve and the lower sleeve is reduced, it extends into the upper sleeve or the lower sleeve, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com