Monorail girder and monorail transportation system

A monorail and track beam technology, which is applied to tracks, roads, buildings, etc., can solve problems such as the impact of performance indicators, unstable driving of power bogies, and reduced fatigue resistance, so as to achieve better lateral stiffness performance and improve system integration. , The effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The scheme will be described below in conjunction with the accompanying drawings and specific implementation methods.

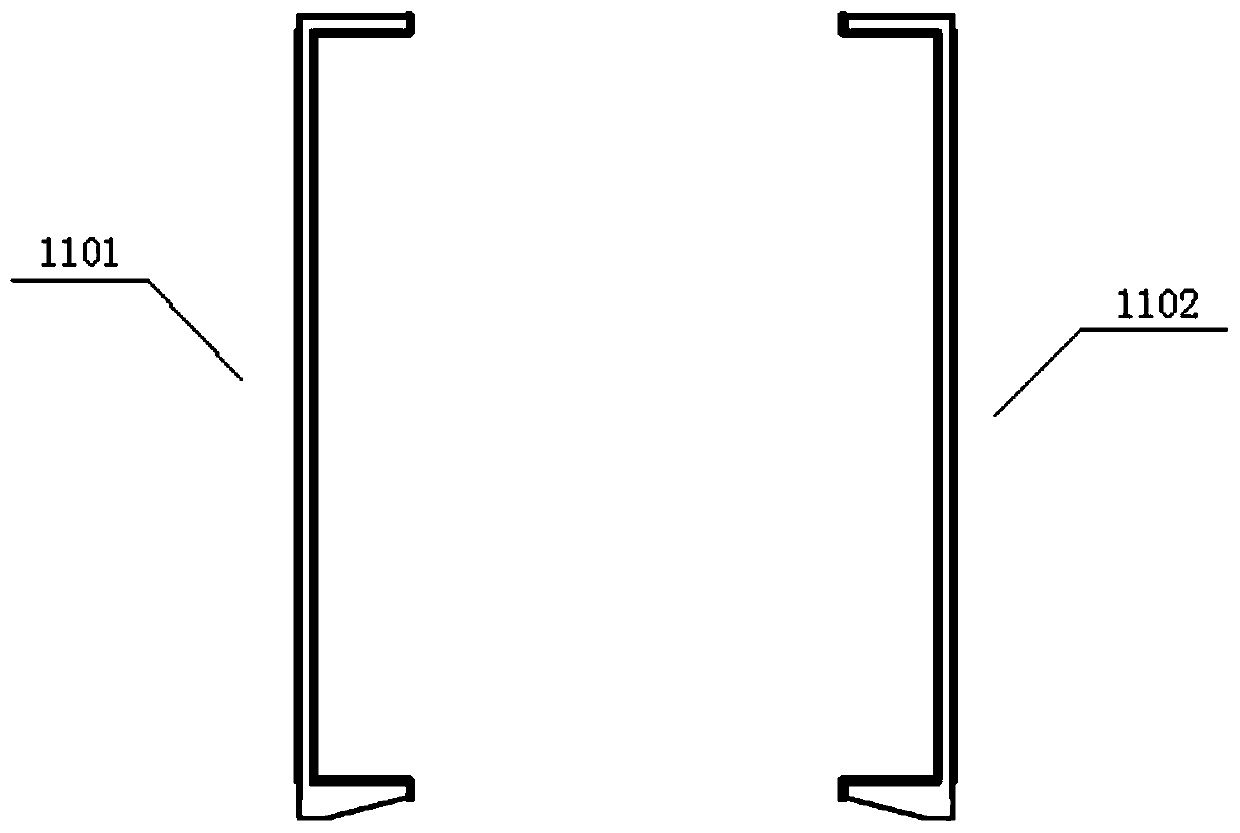

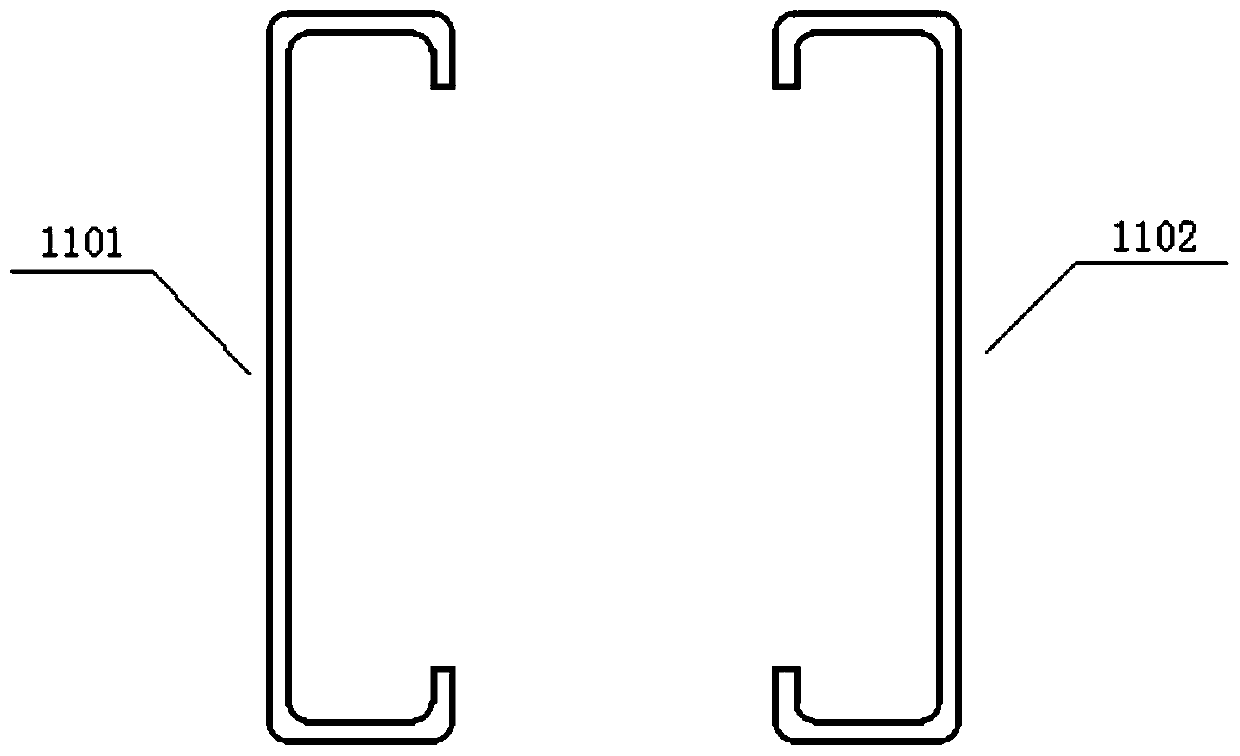

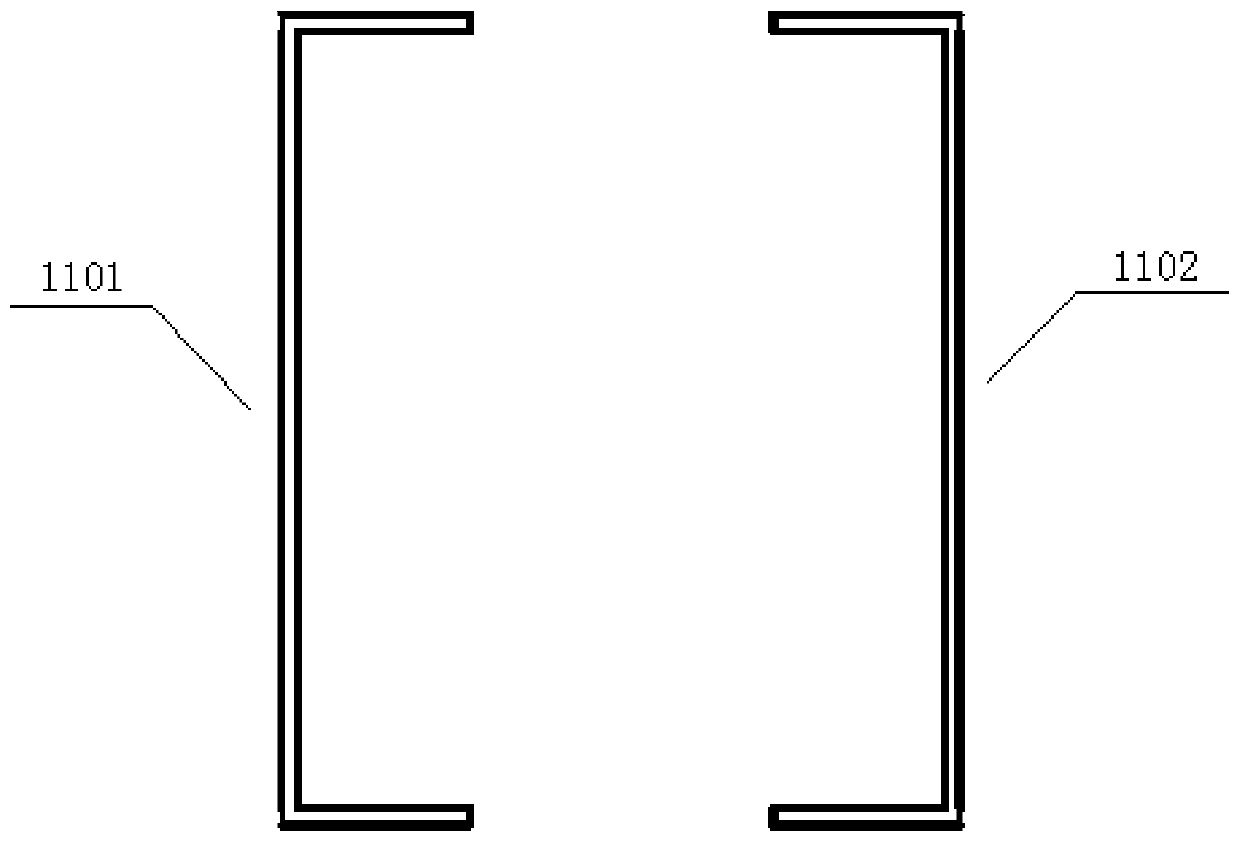

[0037] Please refer to the accompanying drawings, the present application provides a monorail beam, including several track beam units 100; the track beam unit 100 includes at least one assembly and several third bodies 1103, and the assembly includes a mirror-symmetric arrangement of the first A main body 1101 and a second main body 1102, the first main body 1101 and the second main body 1102 are profile structures; the third main body 1103 is a continuous structural member with openings on one side; several third main bodies 1103 are connected to the inner side of the assembly or / and Outside; the assembly is preset to have at least one opening direction that is the same as the opening direction of the third body 1103;

[0038] When several third bodies 1103 are connected to the inner side of the assembly, the continuous space in several third bodies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com