Multifunctional heat pump drying and dehumidifying fresh-keeping equipment

A heat pump drying, multi-functional technology, applied in lighting and heating equipment, drying, dryers and other directions, can solve the problems of inability to purchase, expensive freeze-drying equipment, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

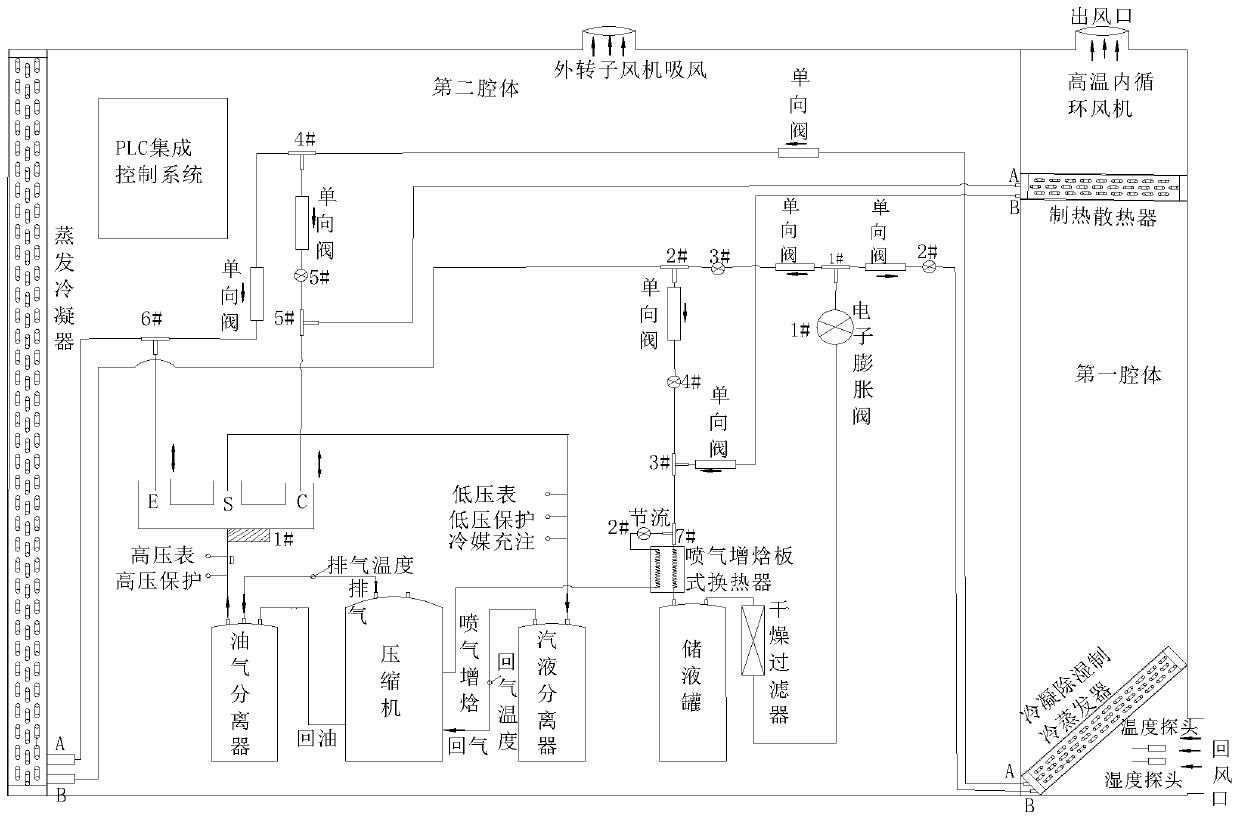

[0052] like figure 1 As shown, the present invention discloses a multifunctional heat pump drying, dehumidification and preservation equipment, comprising: a first cavity and a second cavity;

[0053] The first cavity used to communicate with the drying room to form a closed space is equipped with:

[0054] An evaporator for cold storage, cold constant temperature, and dehumidification, a radiator for heat pump heating, a fan for promoting air flow, and a sensor transmitter for detecting temperature and humidity. Preferably, the fan uses H High-grade high-temperature and high-hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com