Lead-free component interconnection welding spot thermoelectric coupling simulation method

A technology of thermoelectric coupling and simulation method, which can be used in design optimization/simulation, instrumentation, measurement of electricity, etc., and can solve the problem of high time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

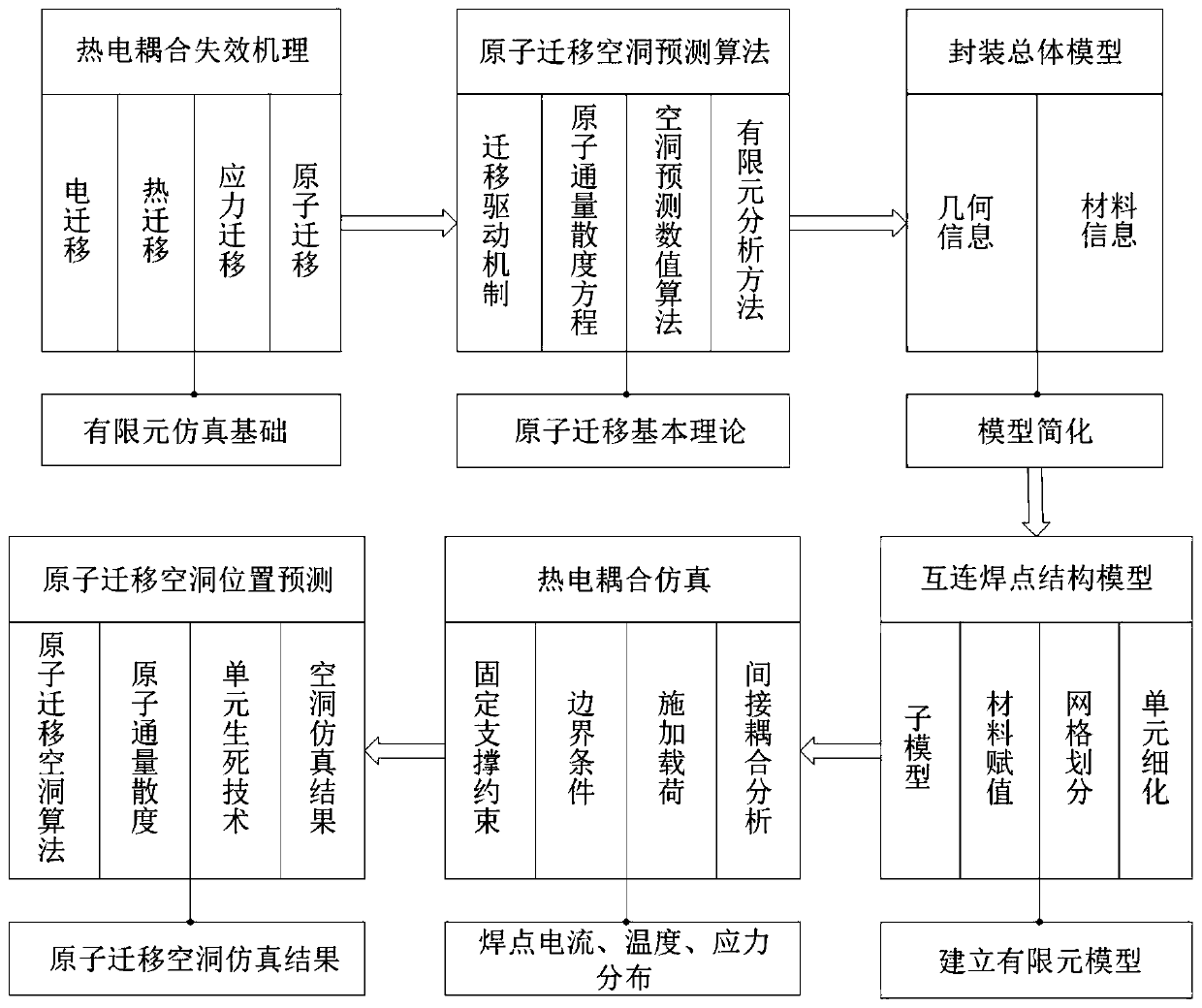

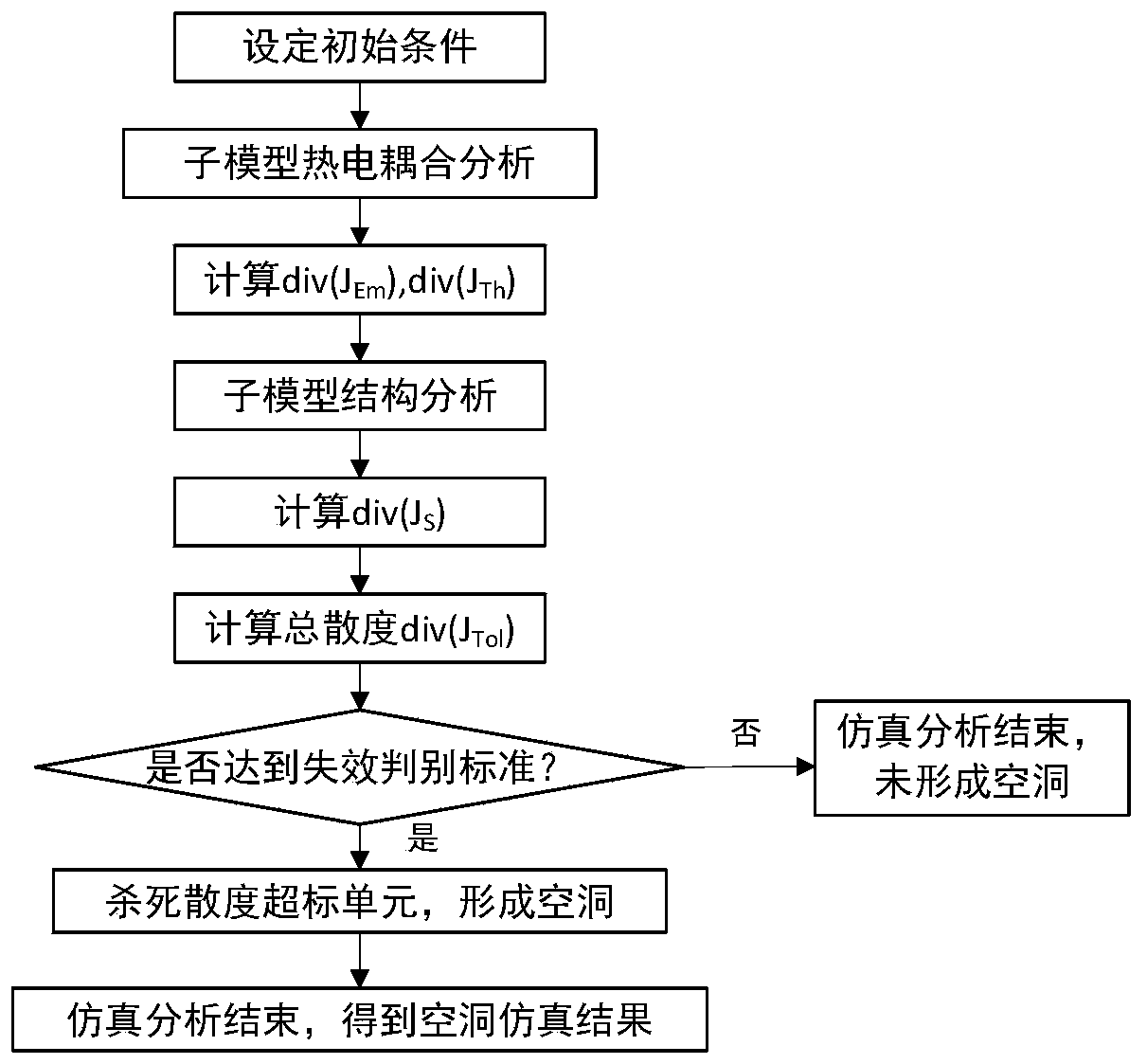

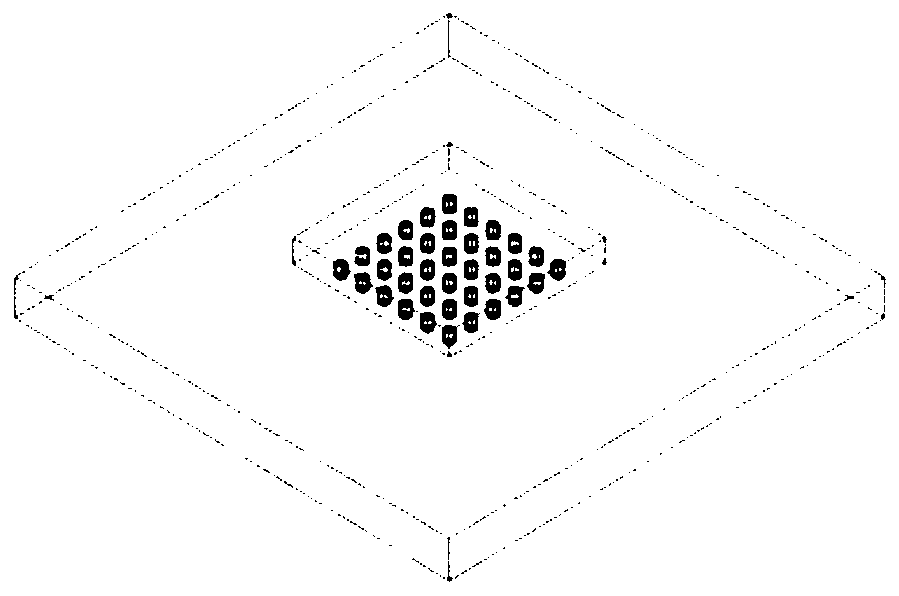

[0036] The method for thermoelectric coupling simulation of interconnect solder joints of lead-free components of the present invention will be further described in detail below in conjunction with the accompanying drawings, and the specific steps are as follows:

[0037] Step 1: Failure mechanism analysis of lead-free component interconnection solder joint thermoelectric coupling

[0038] Under the coupling effect of thermal field and electric field, the main failure mechanism of interconnection solder joints is atomic migration driven by electromigration, thermal migration and stress migration. Due to the current blocking effect, the high current density generates Joule heat in the interconnection solder joints, thereby forming a large temperature gradient, which drives the metal atoms to undergo thermal migration; Perform stress migration. Therefore, the failure of lead-free interconnect solder joints under thermoelectric coupling conditions is actually a common result of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com