Robot casting production line capacity optimization method

A casting production line and optimization method technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as falling into local optimal solutions, and achieve the effects of reducing enterprise logistics costs, optimizing production capacity, and reducing product inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

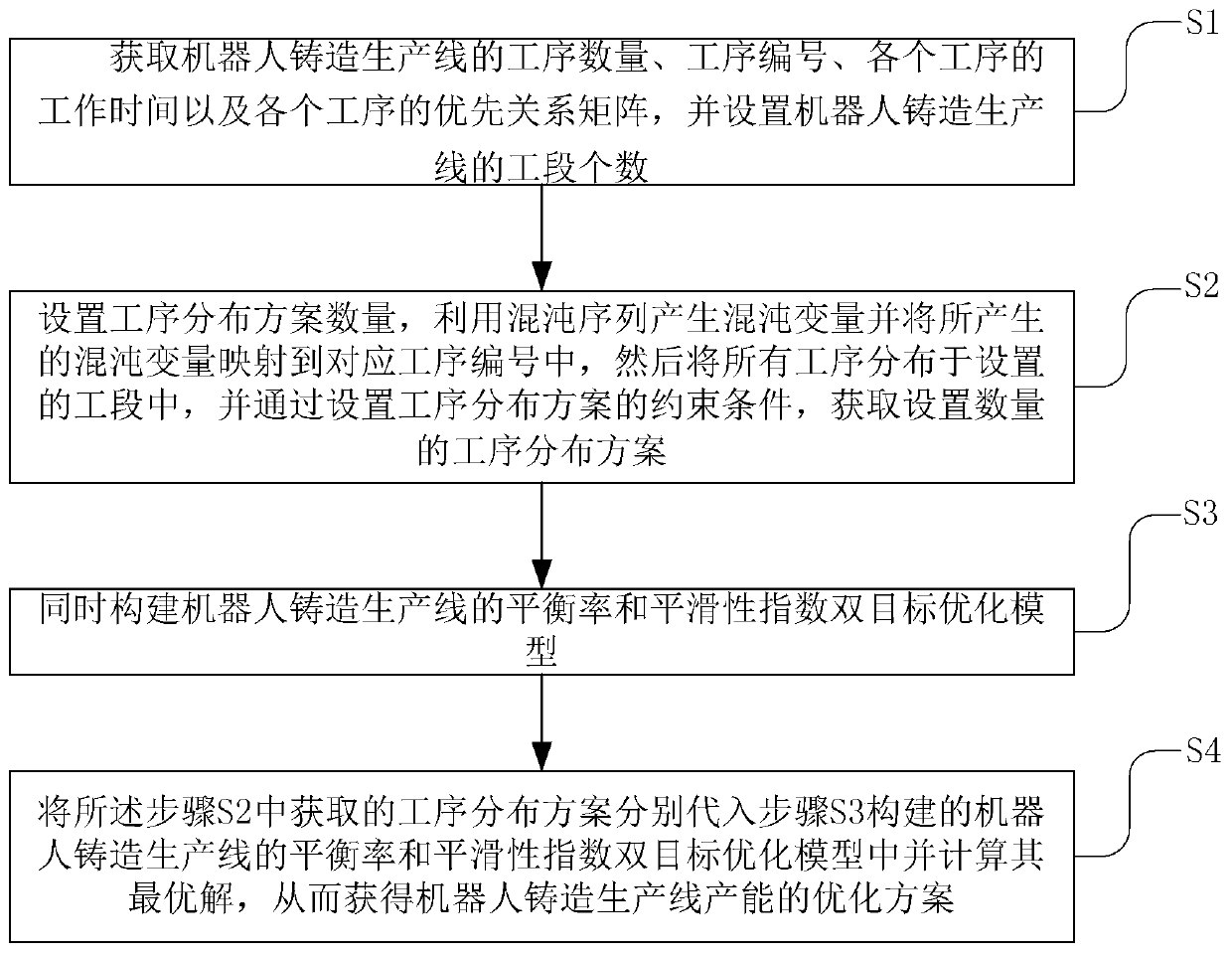

[0059] see figure 1 , figure 1 It is a structural block diagram of an embodiment of the first method for optimizing the production capacity of a robot foundry production line provided by the present invention.

[0060] A method for optimizing the production capacity of a robot casting production line, the method comprising the following steps:

[0061] S1. Obtain the number of processes, process numbers, working hours of each process, and priority relationship matrix of each process in the robot casting production line, and set the number of sections in the robot casting production line;

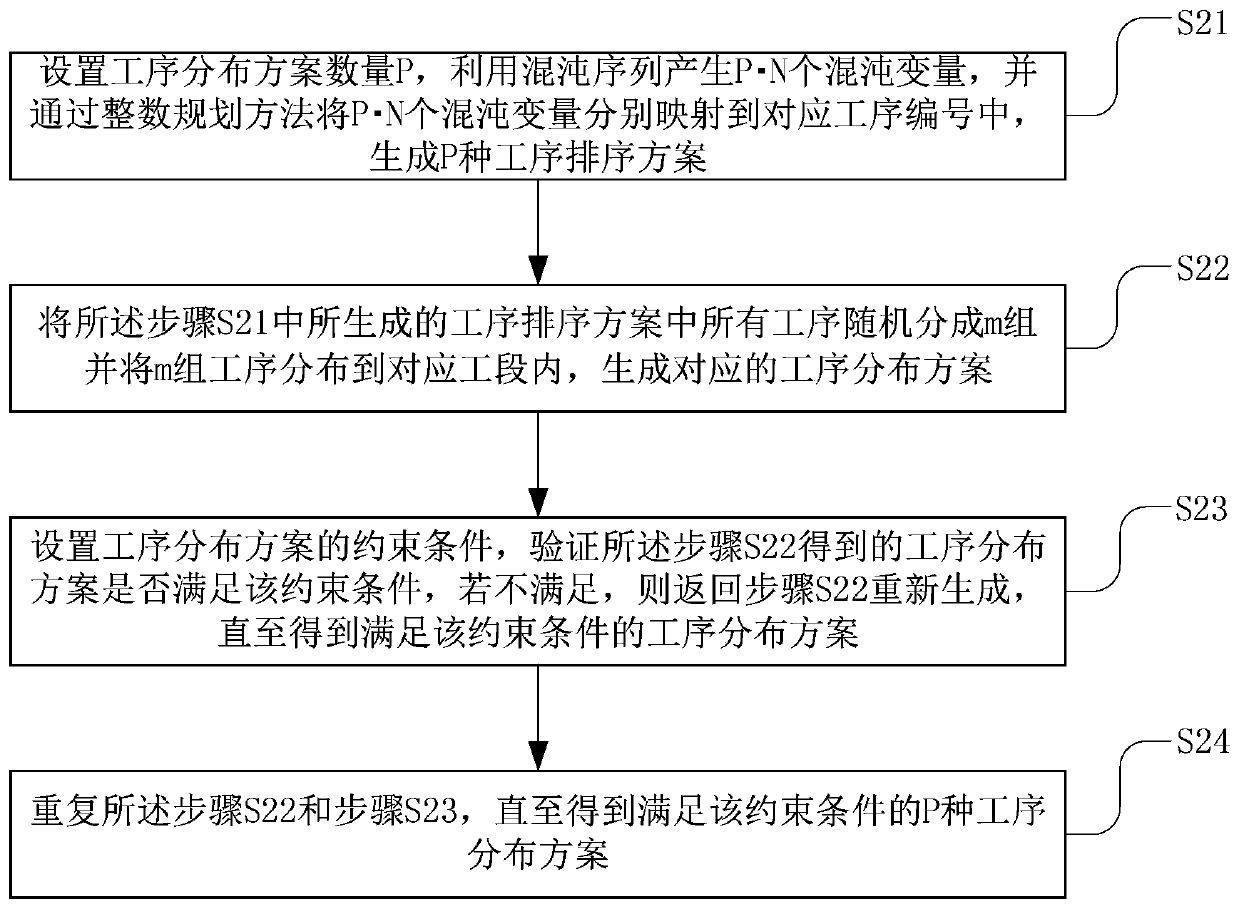

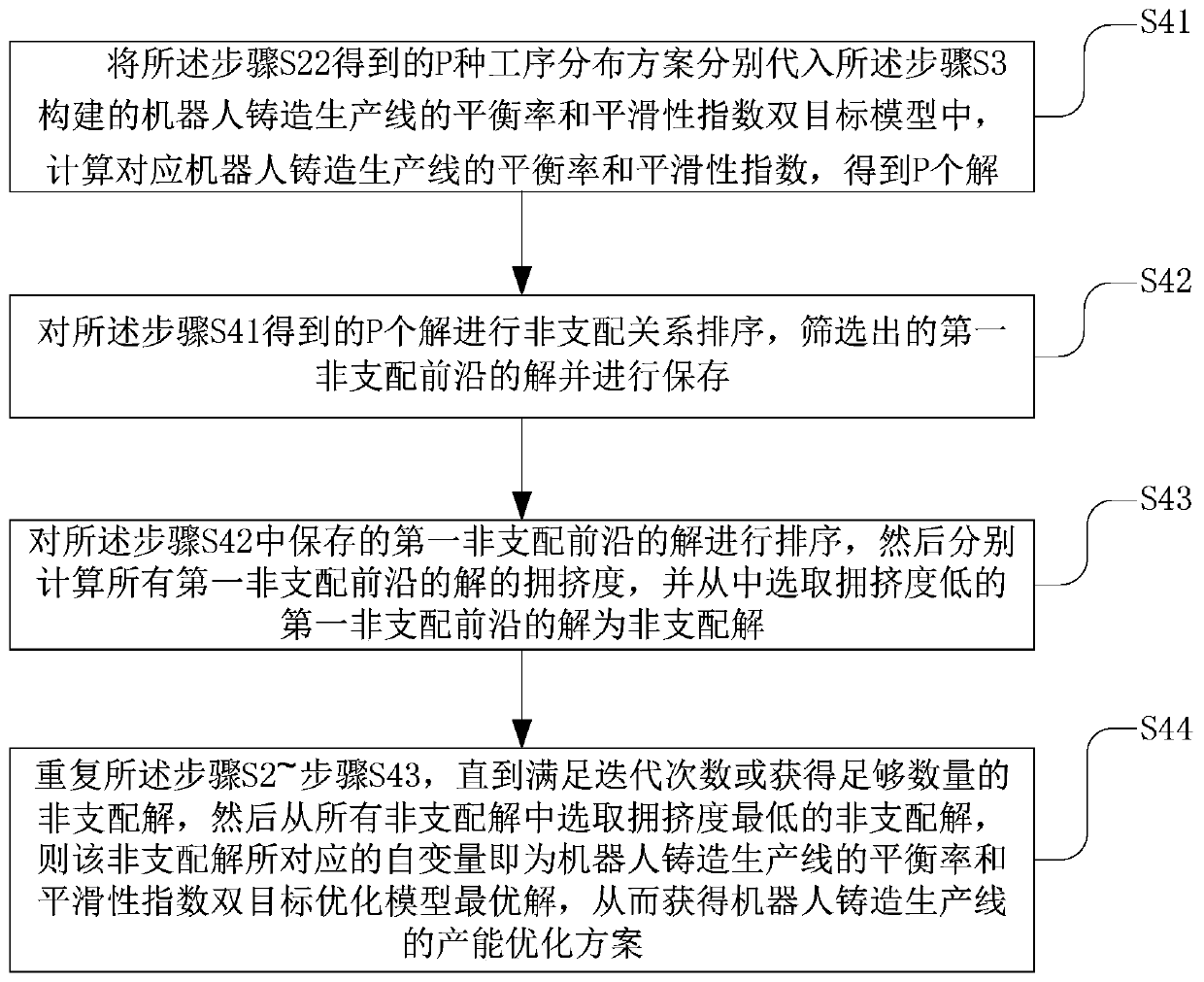

[0062] S2. Set the number of process distribution schemes, use the chaotic sequence to generate chaotic variables and map the generated chaotic variables to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com