Deep hole drilling method for tiny thin-wall components

A technology for thin-walled parts and deep hole drilling, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc. Problems such as eccentric drill bit breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

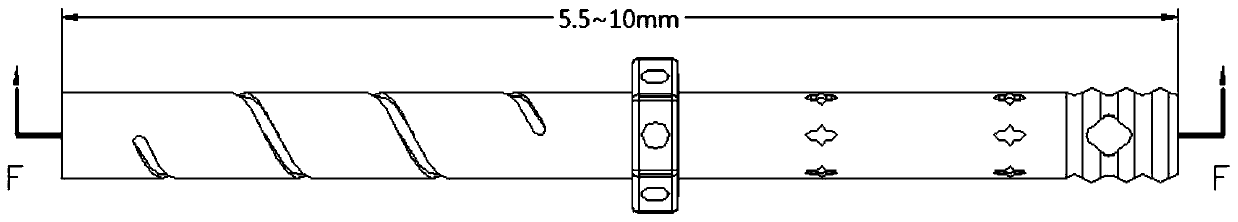

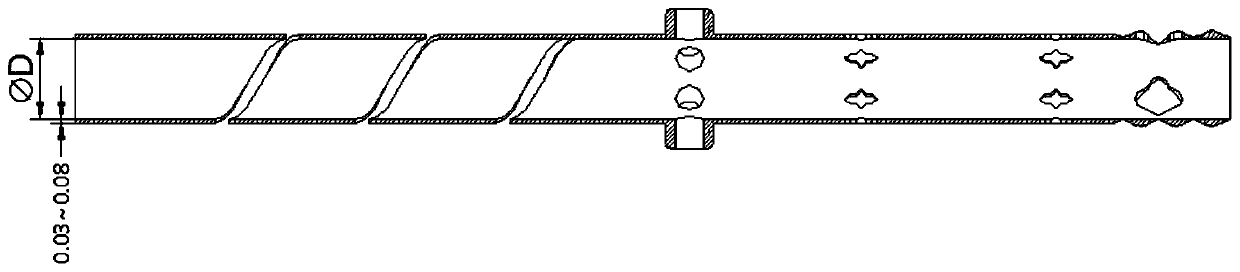

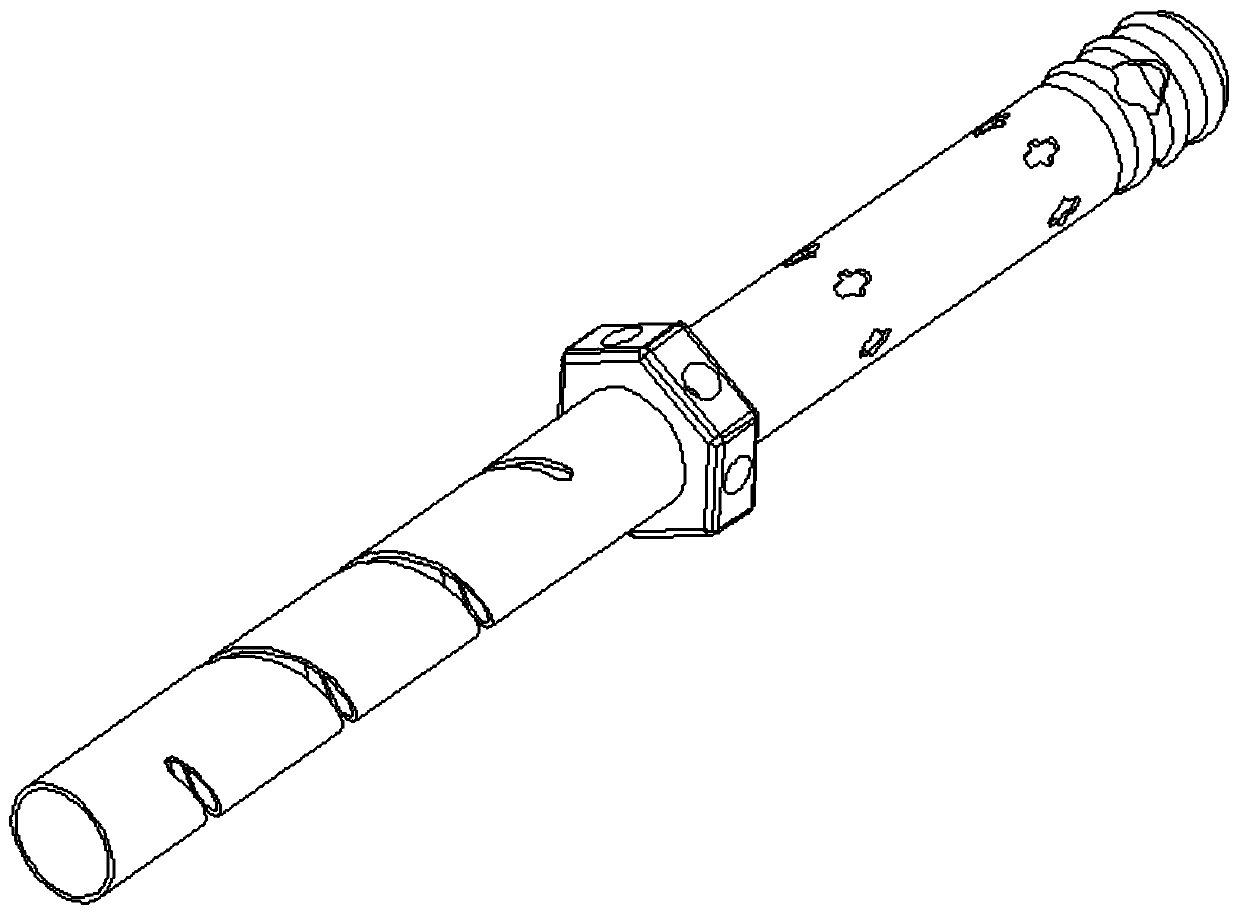

[0027] like figure 1 , figure 2 and image 3 As shown, the tiny thin-walled parts targeted by the present invention have long line diameter ratios, thin walls, and complex structures.

[0028] The present invention adopts following technical scheme: the deep hole drilling method that tiny thin-walled parts are used, it is characterized in that, comprises following 3 steps.

[0029] like Figure 7 As shown, step SS1: use the spot drill to center the product, set the drilling depth and reserve the machining allowance for the next drill bit; as a preferred embodiment, all the steps in the step SS1 The above-mentioned setting of the drilling depth specifically includes: the single feed rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com