Slot turning device for part machining

A technology of parts processing and equipment, applied in the field of lathe equipment for parts processing, can solve the problems of difficult feeding structure, and achieve the effect of slowing down the impact force and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

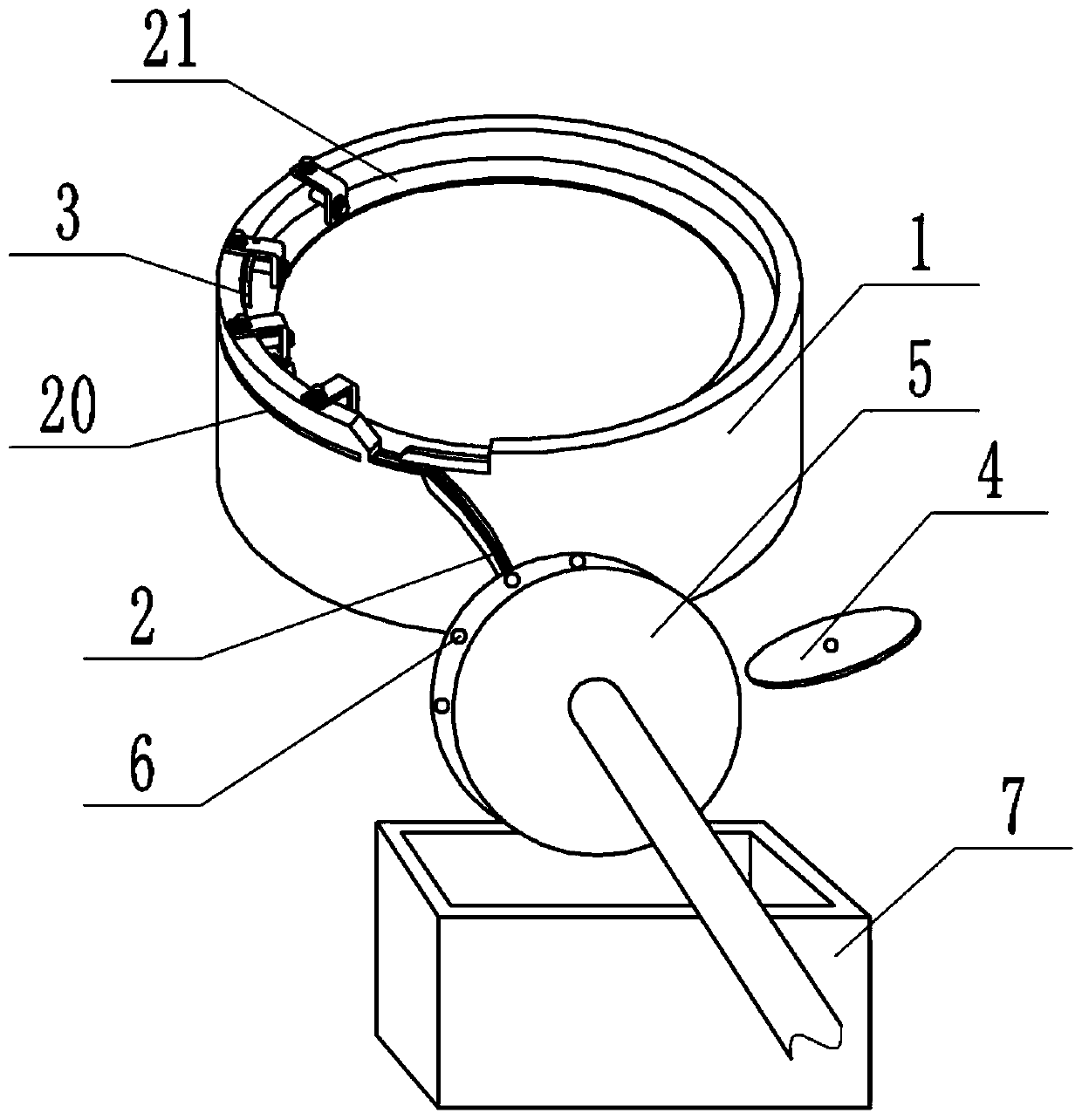

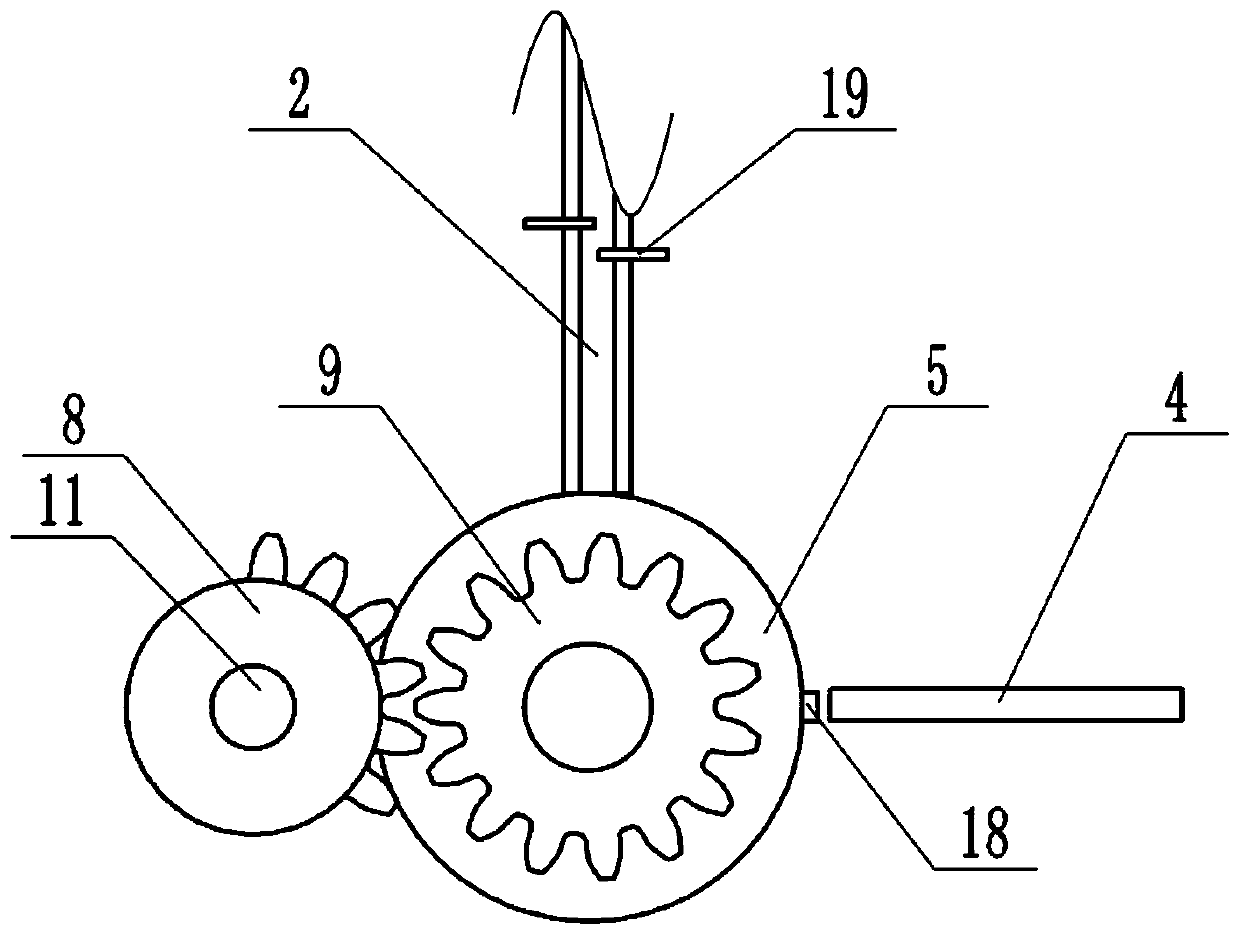

[0033] Such as figure 1 with figure 2 As shown, the lathe equipment for parts processing includes a lathe. The lathe is provided with a feeding structure and a lathe structure. The feeding structure includes a vibrating plate 1 installed on the lathe and a feed rail 2 fixed on the lathe. The vibrating plate 1. A vibrator is fixed at the lower end, the model of the vibrator is: MVE, and the vibrator is connected to an external power supply. The vibrating plate 1 is provided with a guide piece 21 in the shape of a bolt rising, and the side wall of the vibrating plate 1 is located above the guide plate 21 and is provided with a sorting groove 20. The end of the guide piece 21 close to the sorting groove 20 is inclined downward. A straightening wire 3 for correcting the screw is fixed on the top, and a screen opening is also arranged on the deflector 21. The straightening wire 3 is located on one side of the screen opening, and the other side of the screen opening communicates w...

Embodiment 2

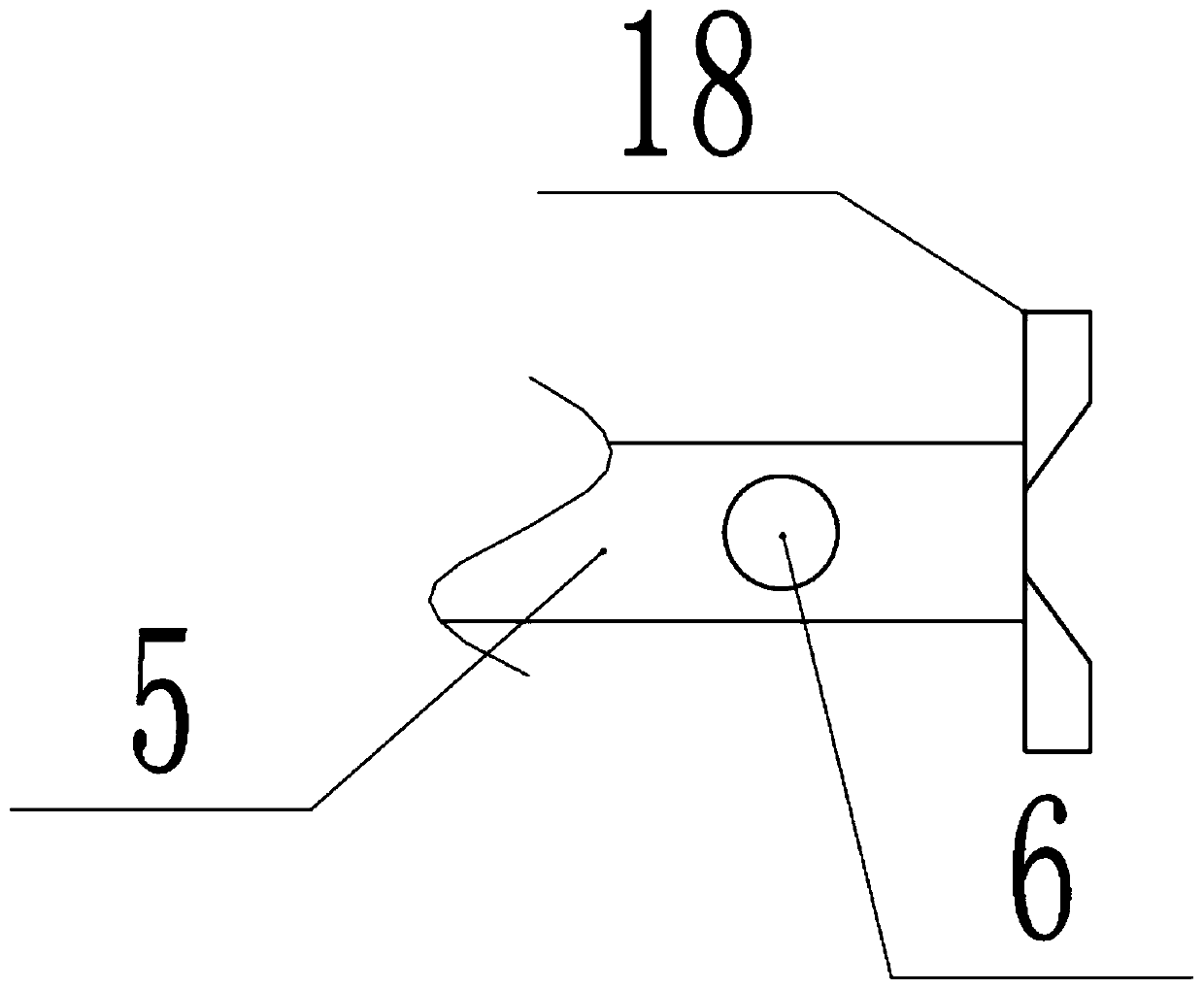

[0041] combine Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, the vehicle tank structure also includes a dust collection box 12 and a dust collection cover, one end of the dust collection cover communicates with the dust collection box 12, and the other end of the dust collection cover is fixed on the block 18 , the opening of the dust cover faces the milling cutter 4. Cam 10 is also fixed on rotating shaft 11, and cam 10 outer wall is provided with cam groove, and connecting rod 14 is slidably connected in the cam groove, and piston 13 is slidably connected in dust collection box 12, and connecting rod 14 runs through and stretches in the dust collection box 12 and And the piston 13 is fixed.

[0042] The dust collecting box 12 is provided with an air inlet and an air outlet, and an air inlet check valve is installed in the air inlet. An air outlet one-way valve is installed in the air outlet, when the air pressure in the dust collection box 12 rises,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com