Tailor welding device applied to box girder

A technology of box girders and beams, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult to ensure the cross-sectional shape of box girders, difficult correction of plates, and thermal deformation of welding, etc., so as to reduce tooling preparation time , Guaranteed cross-sectional shape and axial deformation, and the effect of reducing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

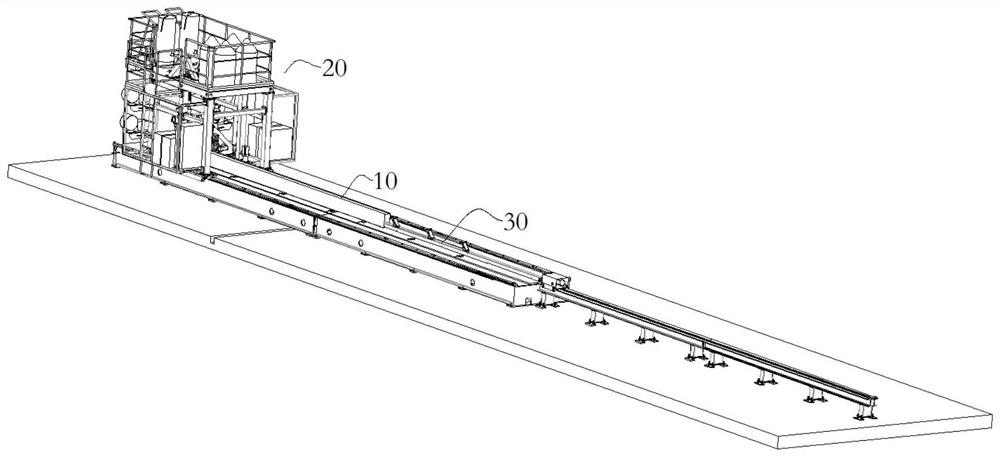

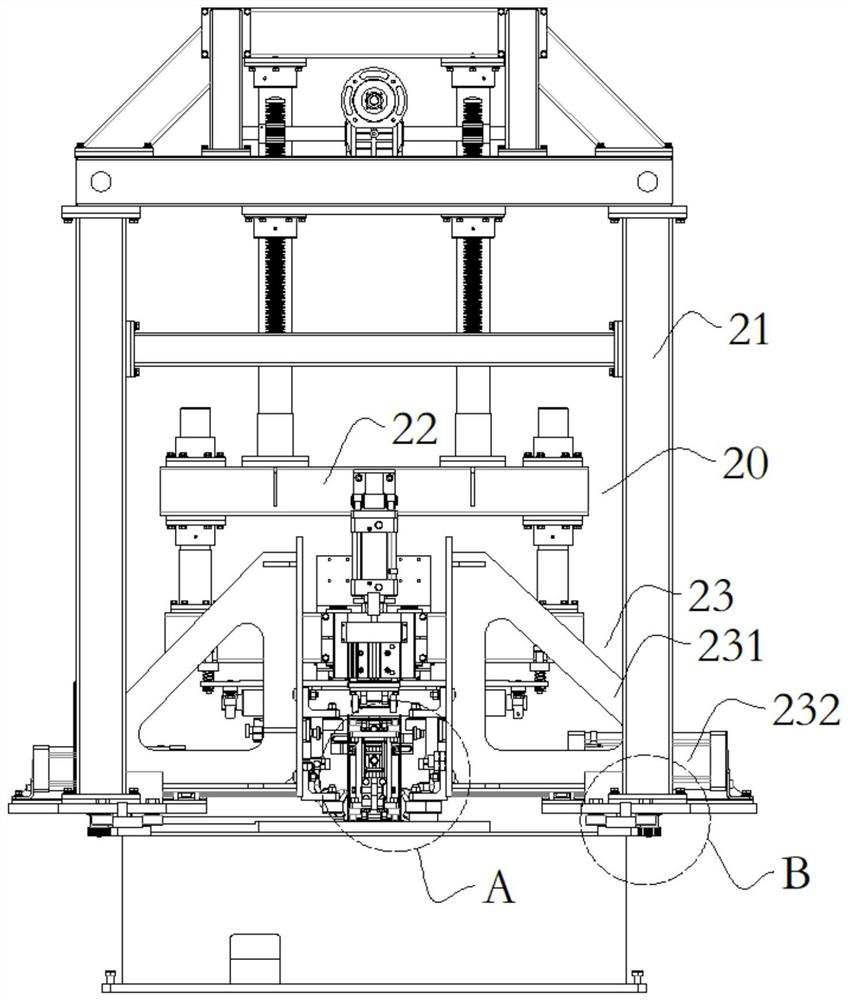

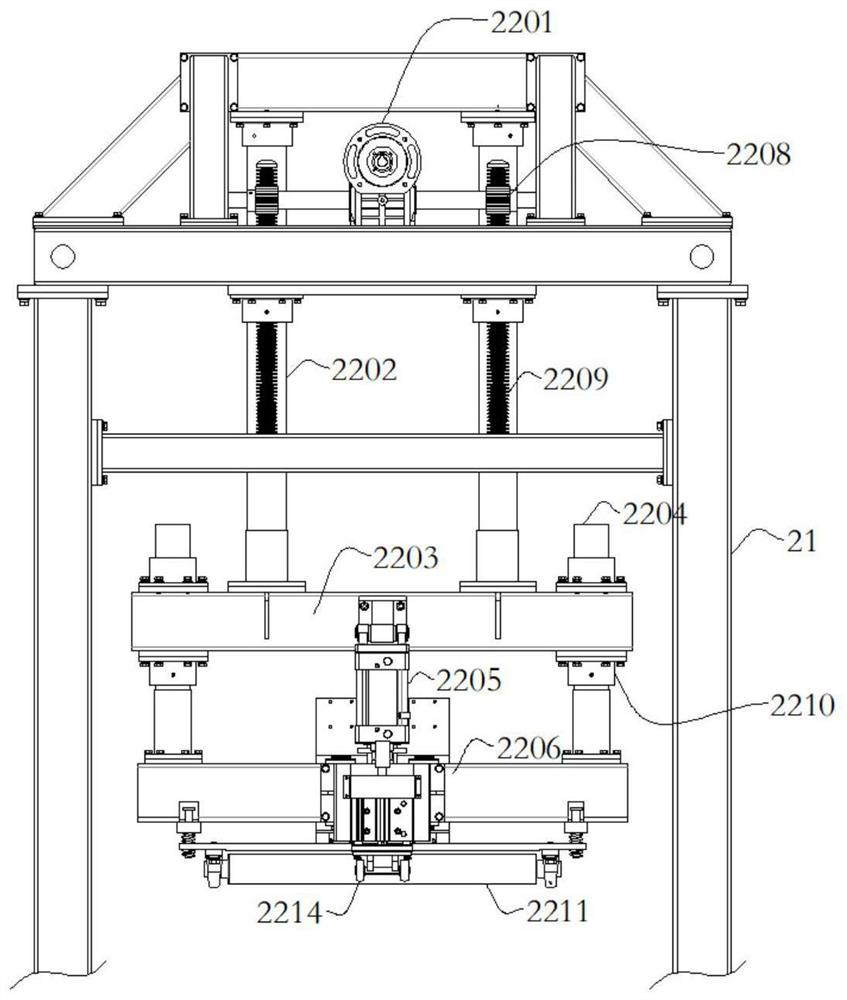

[0035] Such as figure 1 , figure 2 , Figure 8 , Figure 9 As shown, a tailor welding device applied to box girders includes: an external pressing system 20 for pressing each plate of box girder 10 during tailor welding and an external pressing system 20 for making each plate of box girder 10 The inner cavity molding system 30 formed by the parts, the external pressing system 20 includes the gantry 21 and the pressing mechanism 22 arranged on the gantry 21 and a pair of left and right sides of the box girder 10 Clamping mechanism 23, the pressing mechanism 22 is arranged on the top of the box beam 10; the cavity forming system 30 includes a workpiece inner tube 31, a traction frame 32 and a traction mechanism 33, and the workpiece inner tube 31 is arranged on the box beam The inner cavity of the box beam 10 is formed in the inner cavity of the box beam 10, and the position of the workpiece inner tube 31 corresponds to the position of the pressing mechanism 22 of the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com