Sand making machine rotor tailor-welded double-layer positioning template tool and tailor-welded process of sand making machine rotor

A technology for positioning templates and sand making machines, which is used in manufacturing tools, auxiliary devices, welding equipment, etc., can solve the problems of inconvenient use, slow positioning speed, low positioning accuracy, etc. The effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below through specific embodiments.

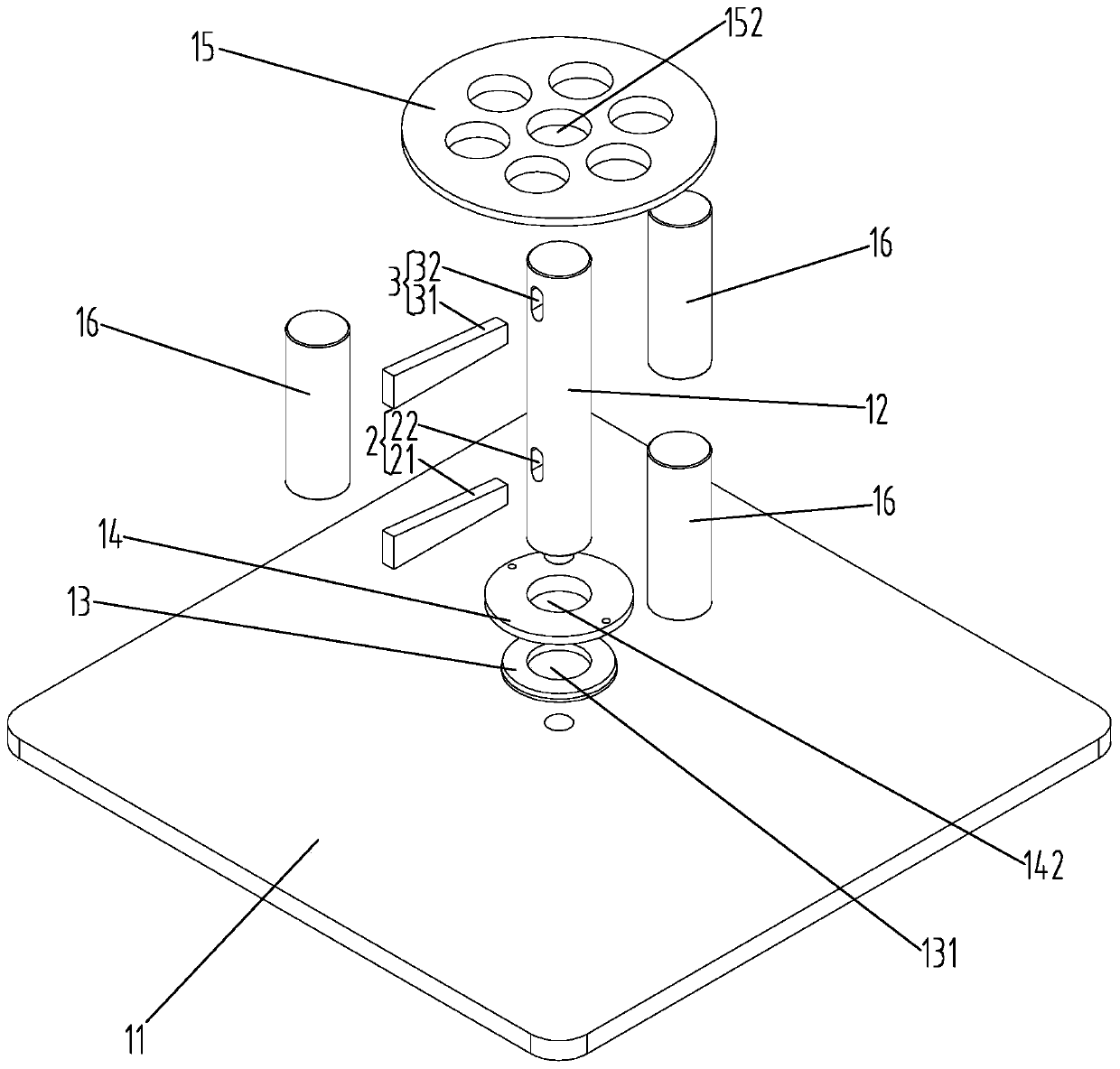

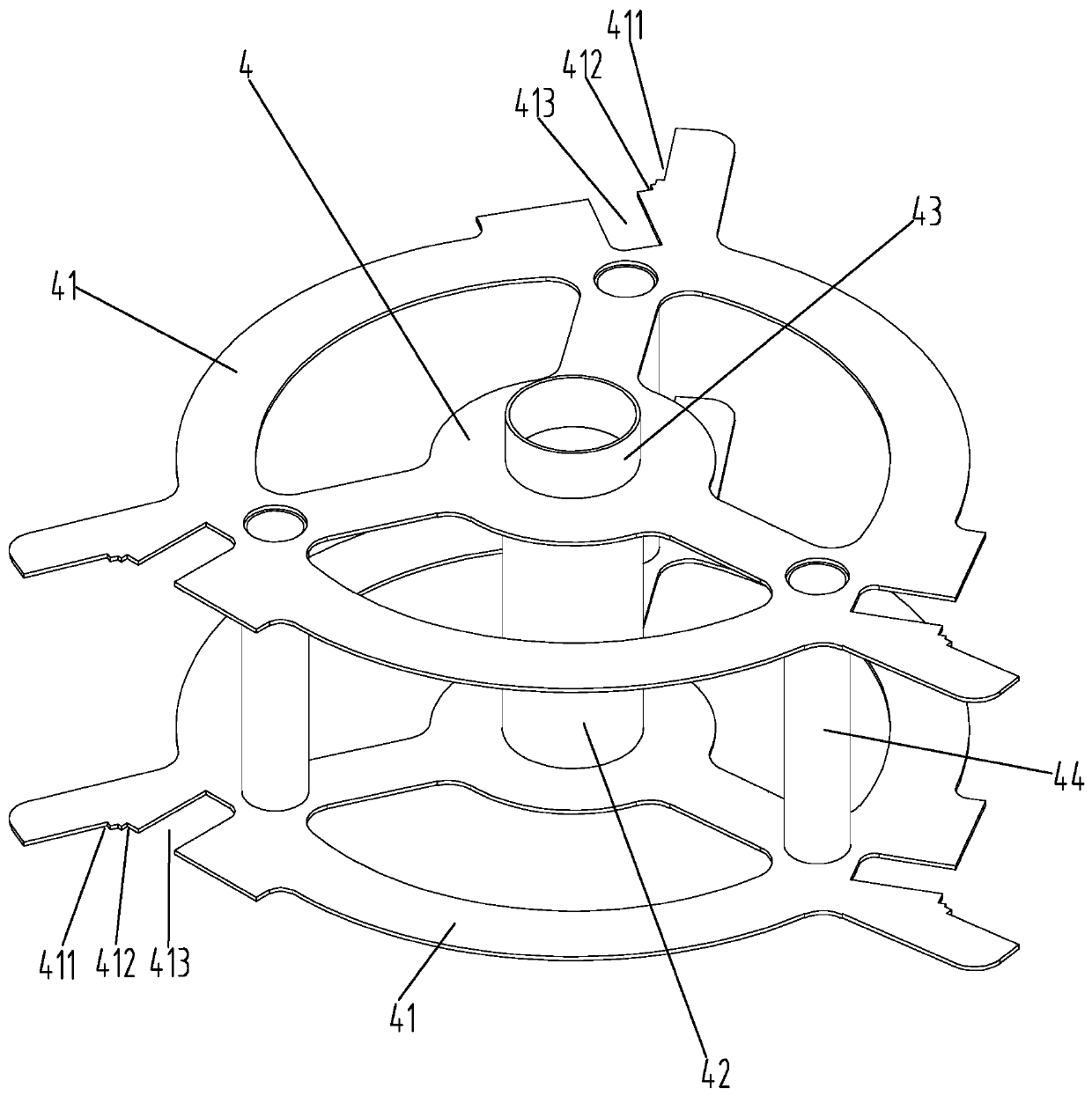

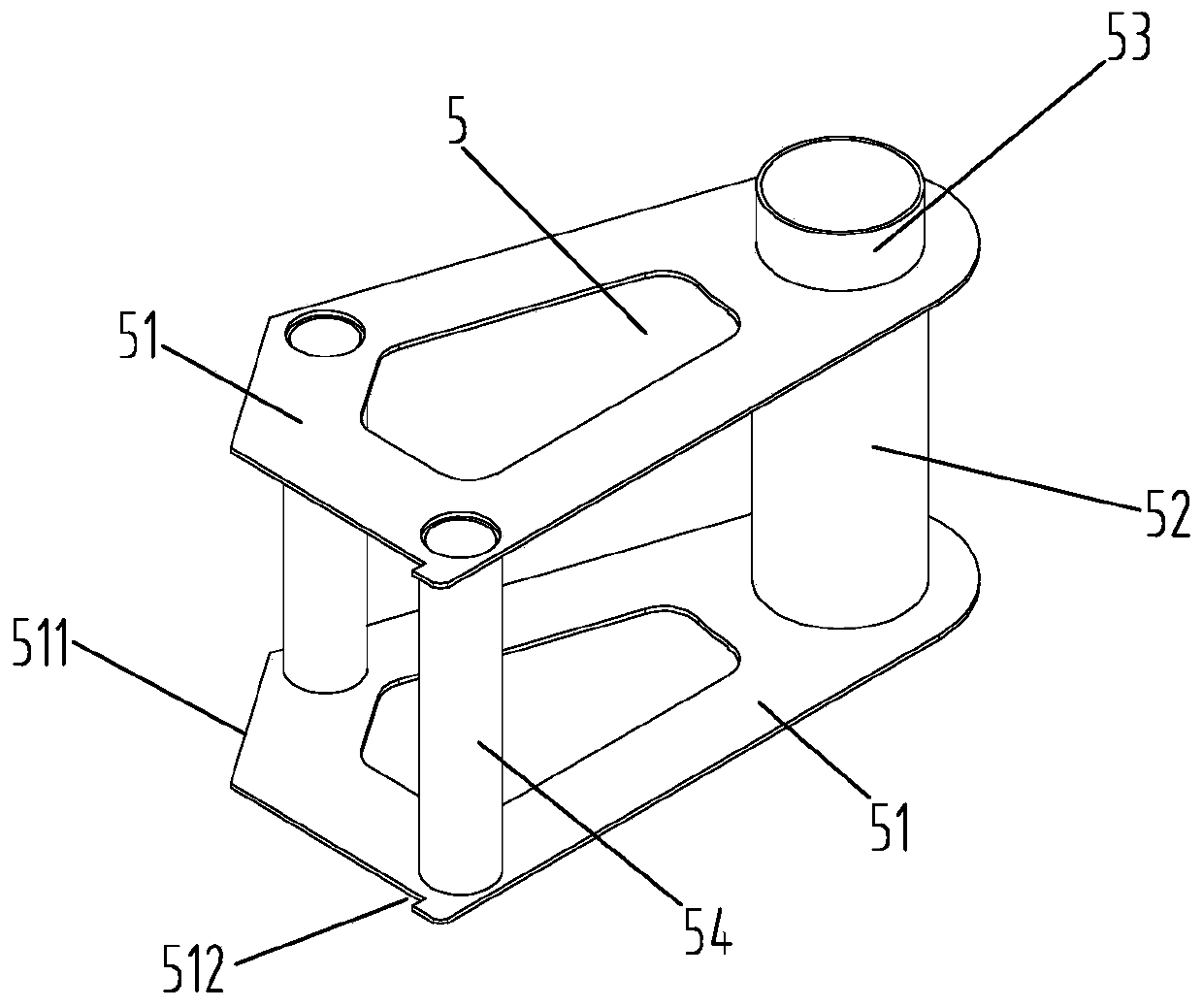

[0052] Such as Figure 1 to Figure 13 As shown, a sand making machine rotor tailor-welded double-layer positioning sample tooling according to the present invention includes a bottom plate 11, on which a main shaft 12 is detachably arranged, and on which a main shaft 12 is sleeved for positioning the rotor. The positioning plate 13 at the bottom of the base 71, the positioning gland 14 for positioning and pressing the top of the base 71 and the end cover 15 for positioning and pressing the upper end plate 72 of the rotor, the lower end plate 73 of the rotor can be A plurality of pads 16 for supporting the upper end plate 72 are placed separately, and the first wedge mechanism 2 for clamping the positioning gland 14 and the first wedge mechanism 2 for clamping the positioning gland 14 are also provided on the spindle 12 . The second wedge mechanism 3 of the end cover 15, the first posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com