A Tailored Welding Method for Large Diameter Steel Pipe Sheets

A large-diameter, steel pipe technology, applied in the field of large-diameter steel pipe tailor welding, can solve the problems of affecting the quality of welds, complicated splicing operations, easy to produce vertical welds, etc., to improve weld quality, reduce vertical welds, reduce The effect of welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

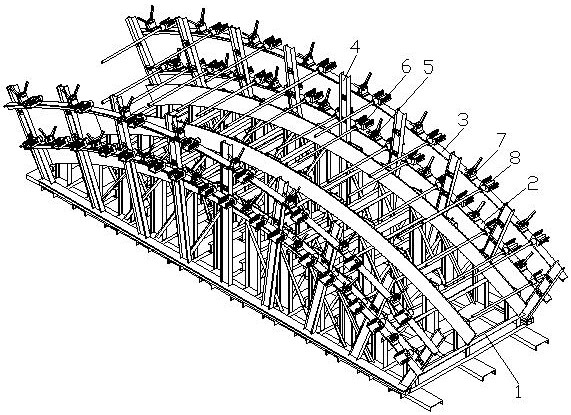

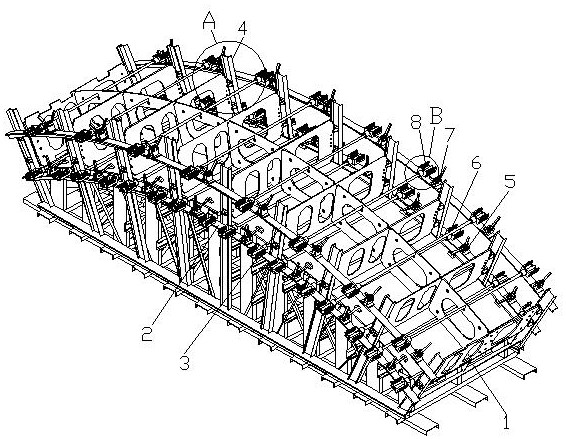

[0041] see Figure 1-Figure 5 , a method for tailor-welding large-diameter steel pipe pieces, comprising the following steps:

[0042] a. Press and fit the inner web on the arched surface of the base 1 of the large-diameter steel pipe piece tailor-welding tool through the inner web presser 5;

[0043] b. The longitudinal partitions are fixed by the longitudinal partition positioning member 4, and the longitudinal partitions are welded to the inner web, and a plurality of longitudinal partitions are fixed in sequence;

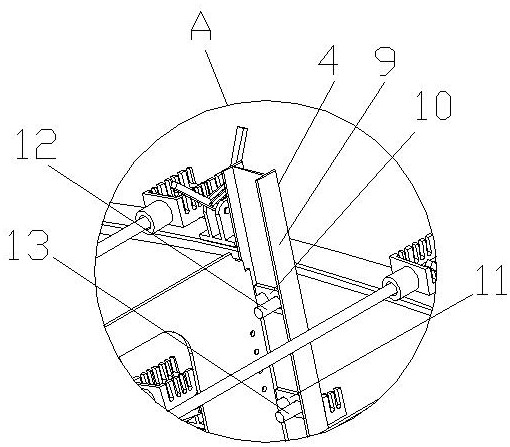

[0044] c. Hoist the horizontal partition, insert the horizontal partition between the two longitudinal partitions, pull the positioning rod 14 to snap the positioning bolt 15 into the fixing slot 18 of the positioning groove 16, and after the positioning bolts 15 on both sides are fixed in place, complete The fixing of the transverse partition, and then welding the transverse partition with the inner web and the adjacent longitudinal partition;

[0045] d. Acc...

Embodiment 2

[0048] see Figure 1-Figure 5 , a method for tailor-welding large-diameter steel pipe pieces, comprising the following steps:

[0049] a. Press and fit the inner web on the arched surface of the base 1 of the large-diameter steel pipe piece tailor-welding tool through the inner web presser 5;

[0050] b. The longitudinal partitions are fixed by the longitudinal partition positioning member 4, and the longitudinal partitions are welded to the inner web, and a plurality of longitudinal partitions are fixed in sequence;

[0051] c. Hoist the horizontal partition, insert the horizontal partition between the two longitudinal partitions, pull the positioning rod 14 to snap the positioning bolt 15 into the fixing slot 18 of the positioning groove 16, and after the positioning bolts 15 on both sides are fixed in place, complete The fixing of the transverse partition, and then welding the transverse partition with the inner web and the adjacent longitudinal partition;

[0052] d. Acc...

Embodiment 3

[0056] see Figure 1-Figure 5 , a method for tailor-welding large-diameter steel pipe pieces, comprising the following steps:

[0057] a. Press and fit the inner web on the arched surface of the base 1 of the large-diameter steel pipe piece tailor-welding tool through the inner web presser 5;

[0058] b. The longitudinal partitions are fixed by the longitudinal partition positioning member 4, and the longitudinal partitions are welded to the inner web, and a plurality of longitudinal partitions are fixed in sequence;

[0059] c. Hoist the horizontal partition, insert the horizontal partition between the two longitudinal partitions, pull the positioning rod 14 to snap the positioning bolt 15 into the fixing slot 18 of the positioning groove 16, and after the positioning bolts 15 on both sides are fixed in place, complete The fixing of the transverse partition, and then welding the transverse partition with the inner web and the adjacent longitudinal partition;

[0060] d. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com