Engine galvanic pile and hydrogen pipe component assembling production line

A technology for assembling production lines and hydrogen pipes, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as poor continuity, reduced assembly efficiency, and heavy engine parts, so as to improve production and assembly efficiency, reduce the transfer process, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention by those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and drawings.

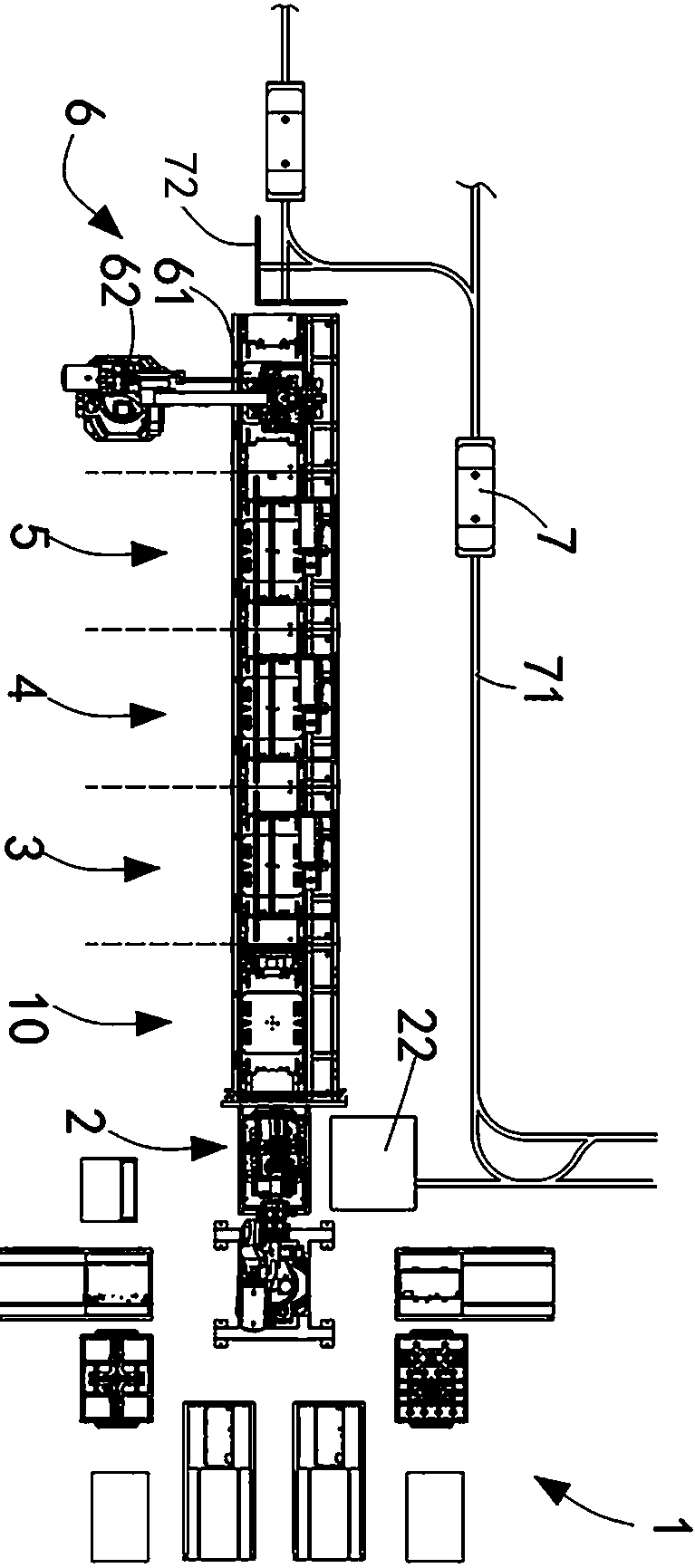

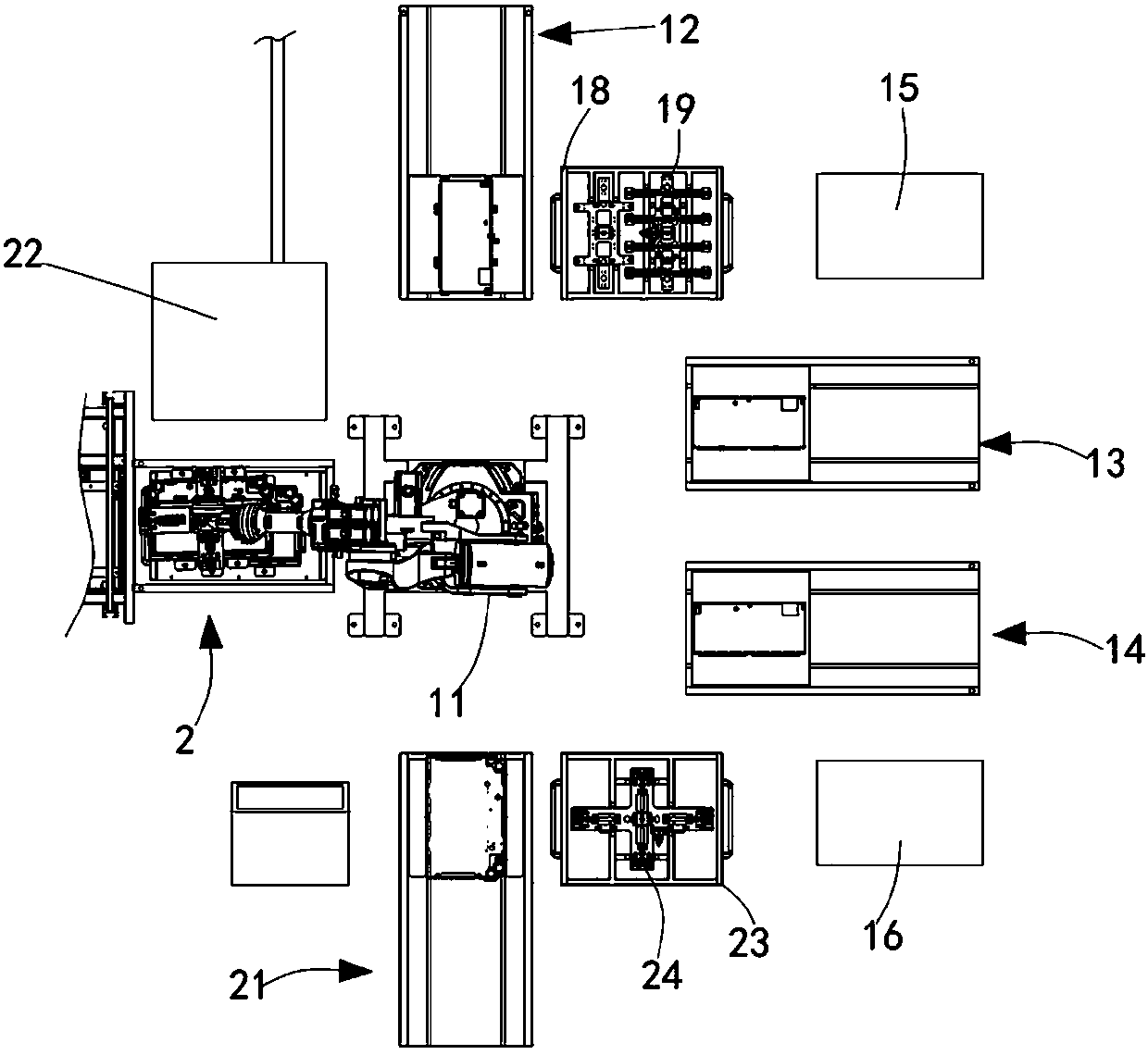

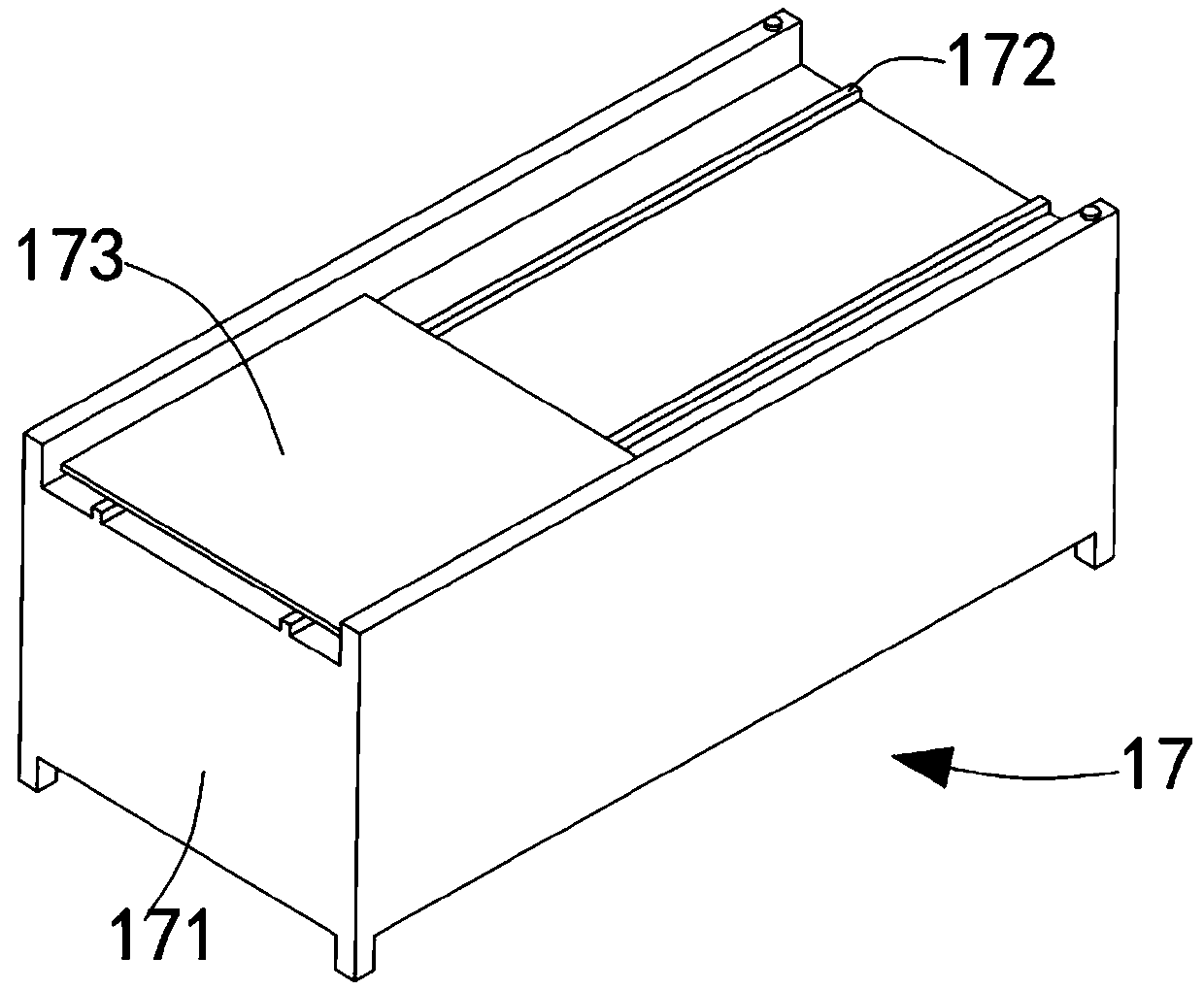

[0025] Reference Figure 1 to Figure 7 , The present invention provides an engine stack and hydrogen tube assembly assembly production line including a stack assembly workstation 1 for assembling the stack, a cylinder block workstation 2 for connecting the stack and the engine block, and the hydrogen tube assembly The intake pipe assembly workstation 3 for the assembly connection of the intake pipe and the engine block, the outlet pipe assembly workstation 4 for the assembly connection of the outlet pipe of the hydrogen pipe assembly and the engine block, and the air tightness test for checking the air tightness of the hydrogen pipe assembly Workstation 5, a discharging workstation 6 for discharging the assembled engine block, and multiple AGV vehicles 7 for tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com