Knife sharpening reciprocating mechanism of shredding machine

A technology of reciprocating mechanism and wire cutting machine, which is applied in the direction of grinding frame, grinding bed, grinding slide plate, etc. It can solve the problem that the linear motor cannot be continuously driven, and achieves the advantages of simple structure, easy maintenance and increased service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

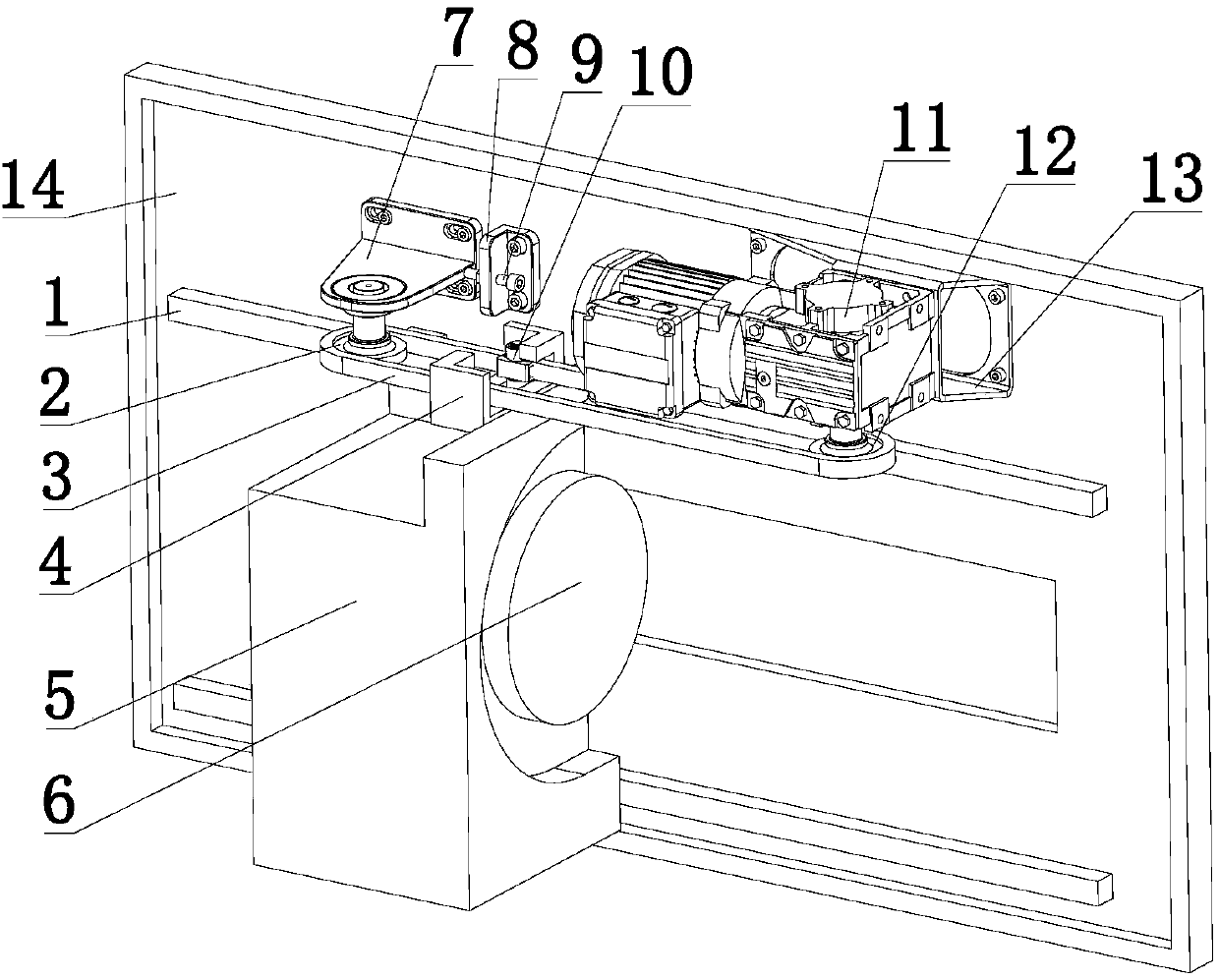

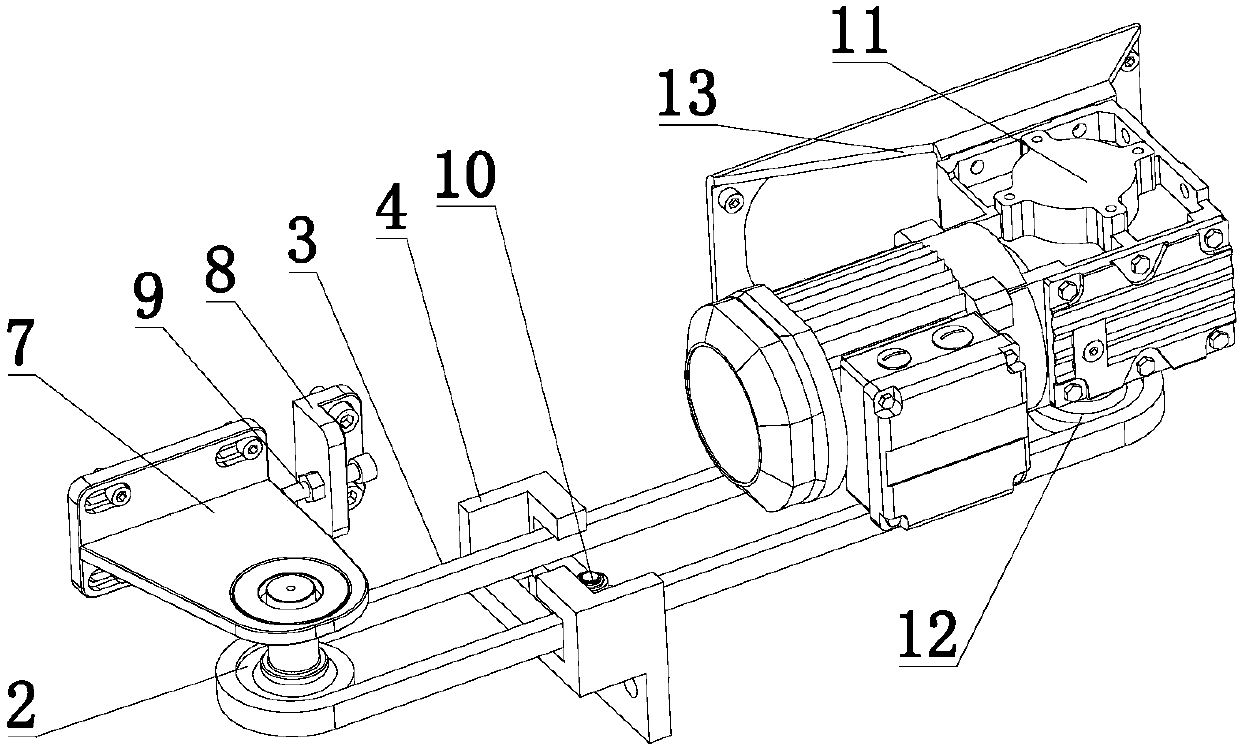

[0044] Such as Figure 1 to Figure 2 As shown, the adjustment device of a sharpening reciprocating mechanism of a shredder described in this embodiment, the adjustment device is movably installed on the sharpening bottom plate 14, the driven wheel 2 is connected with the adjustment device, and the adjustment device moves to drive the slave The driving wheel 2 adjusts the distance between the driven wheel 2 and the driving wheel 12 .

[0045] Specifically, the adjustment device includes a driving seat 8 and a driven seat 7, the driving seat 8 is connected to the knife sharpening base plate 14, and the driven seat 7 is movably installed on the knife sharpening base plate 14, and the driving seat 8 is provided with The retractable ejector rod 9, the ejector rod 9 promotes the driven seat 7 to move on the sharpening base plate 14.

[0046] In detail, the driven seat 7 is provided with a long hole, and is movably connected to the knife sharpening base plate 14 through the bolts pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com