Threading cable centering device, S-shaped mechanical arm and application method of S-shaped mechanical arm

A technology for centering device and cable, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high precision requirements for wire hole processing, shortened cable life cycle, cable wear, etc. The effect of reduced precision requirements, reduced drive force, easy removal and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

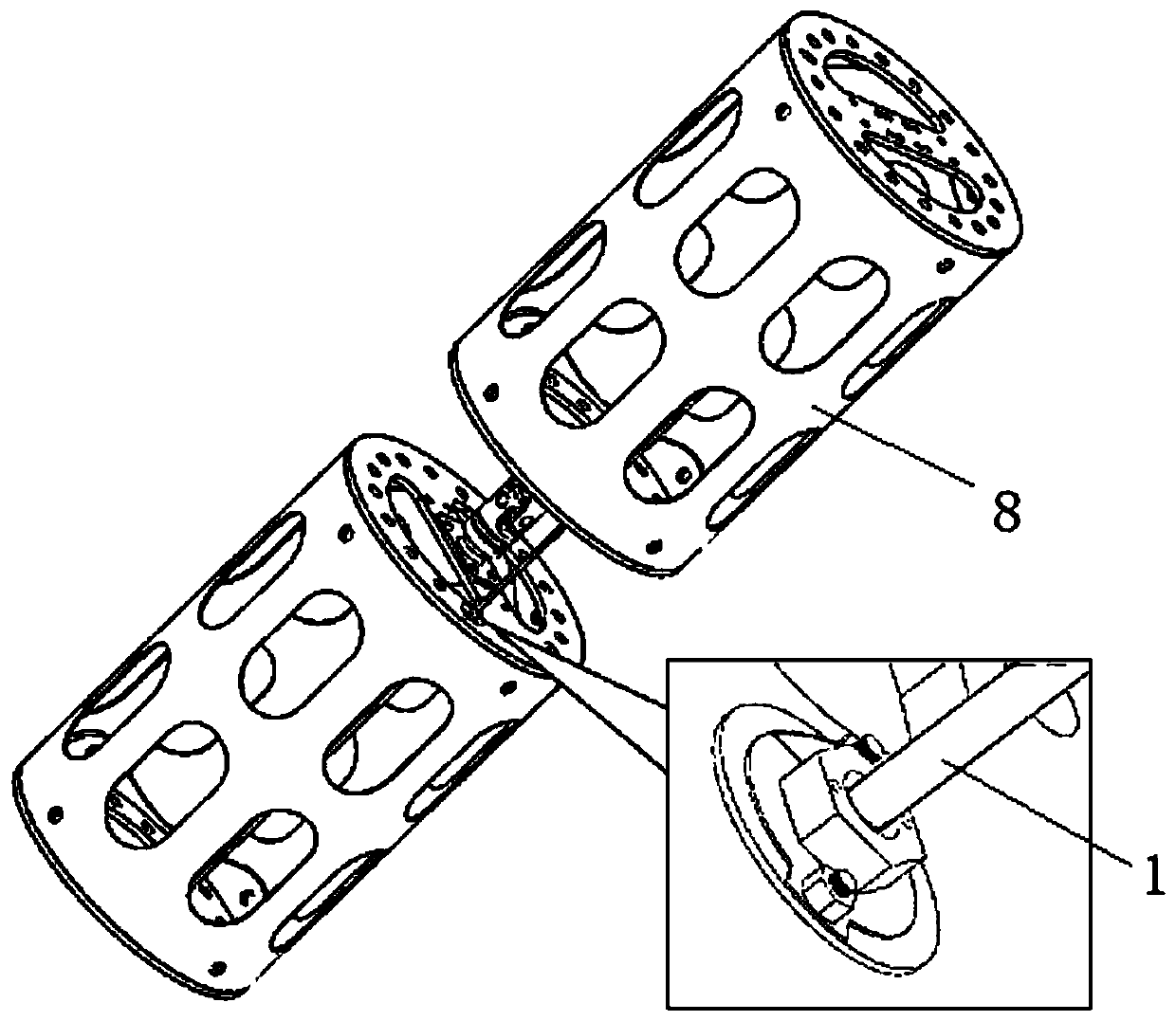

[0064] The snake-arm robot is a super-redundant robotic arm driven by cables. The main structure includes linear guides, drive packages, bases, snake arms, cables, universal joints and end effectors. The base is fixed on the drive package, and all the driving of the snake arm robot is done by stretching the cables in the drive package, wherein each snake arm is driven by 3 cables evenly distributed at 120°.

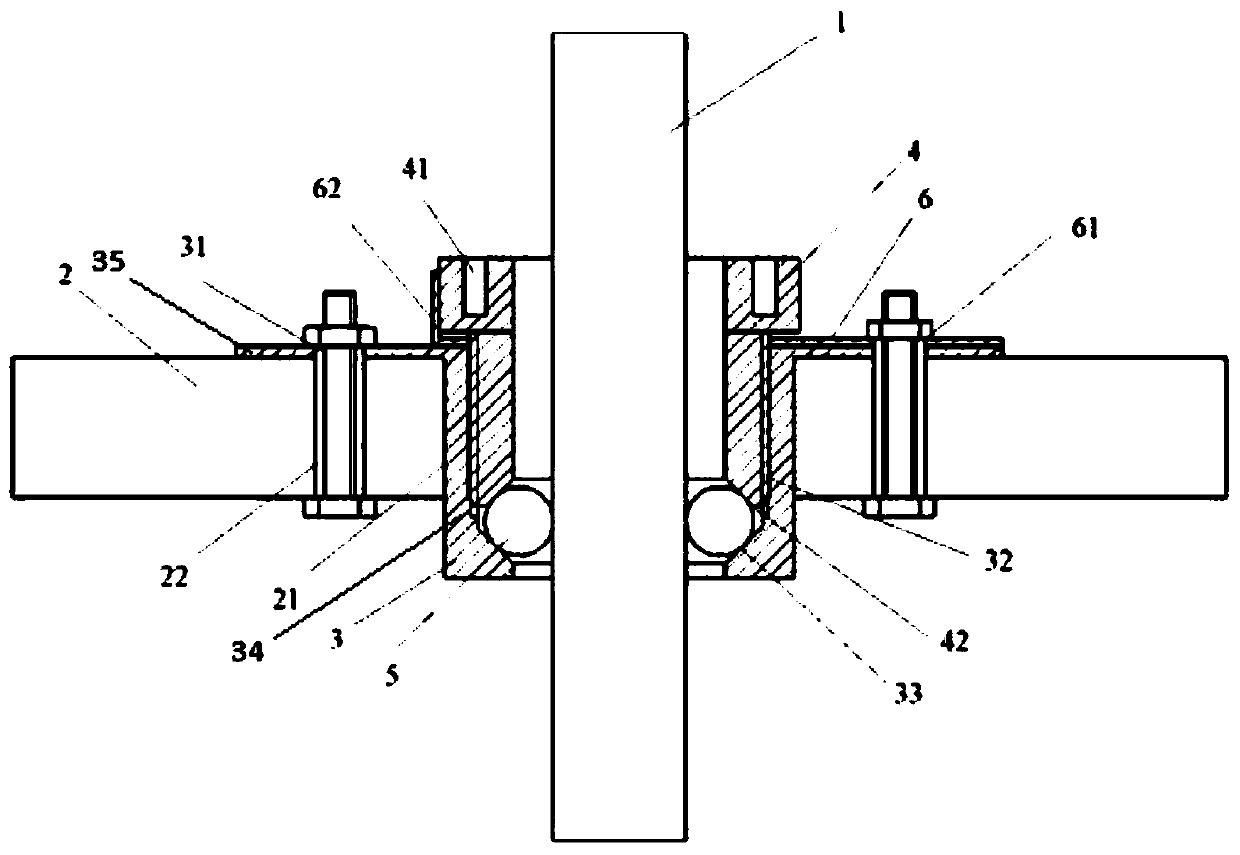

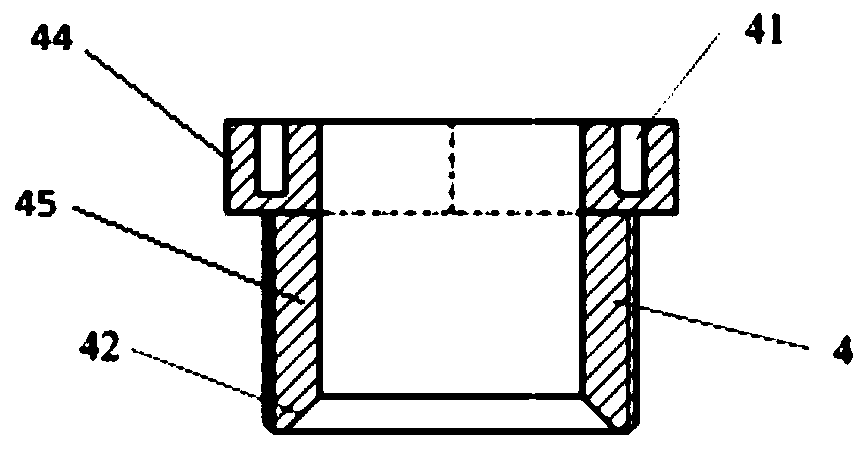

[0065] The present invention provides a via hole cable centering device for a wire-driven robot (snake-shaped arm robot). figure 1 For some two segments 8 of the line-driven snake-arm robot, the effect diagram of the installation of the device, figure 2 It is a partial cross-sectional view of the structure of the device. The complete device includes a fixing structure 3 , an adjusting structure 4 , a ball 5 and an anti-loosening washer structure 6 . Also in figure 1 Among them, the cable 1 is the cable to be passed through the cable hole 21 , and the cable hole 21 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com