Low-nitrogen oxide combustor

A low-nitrogen oxide, burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problem of insignificant NOx emission effect, and achieve stable combustion performance, lower combustion temperature, and lower NOx emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

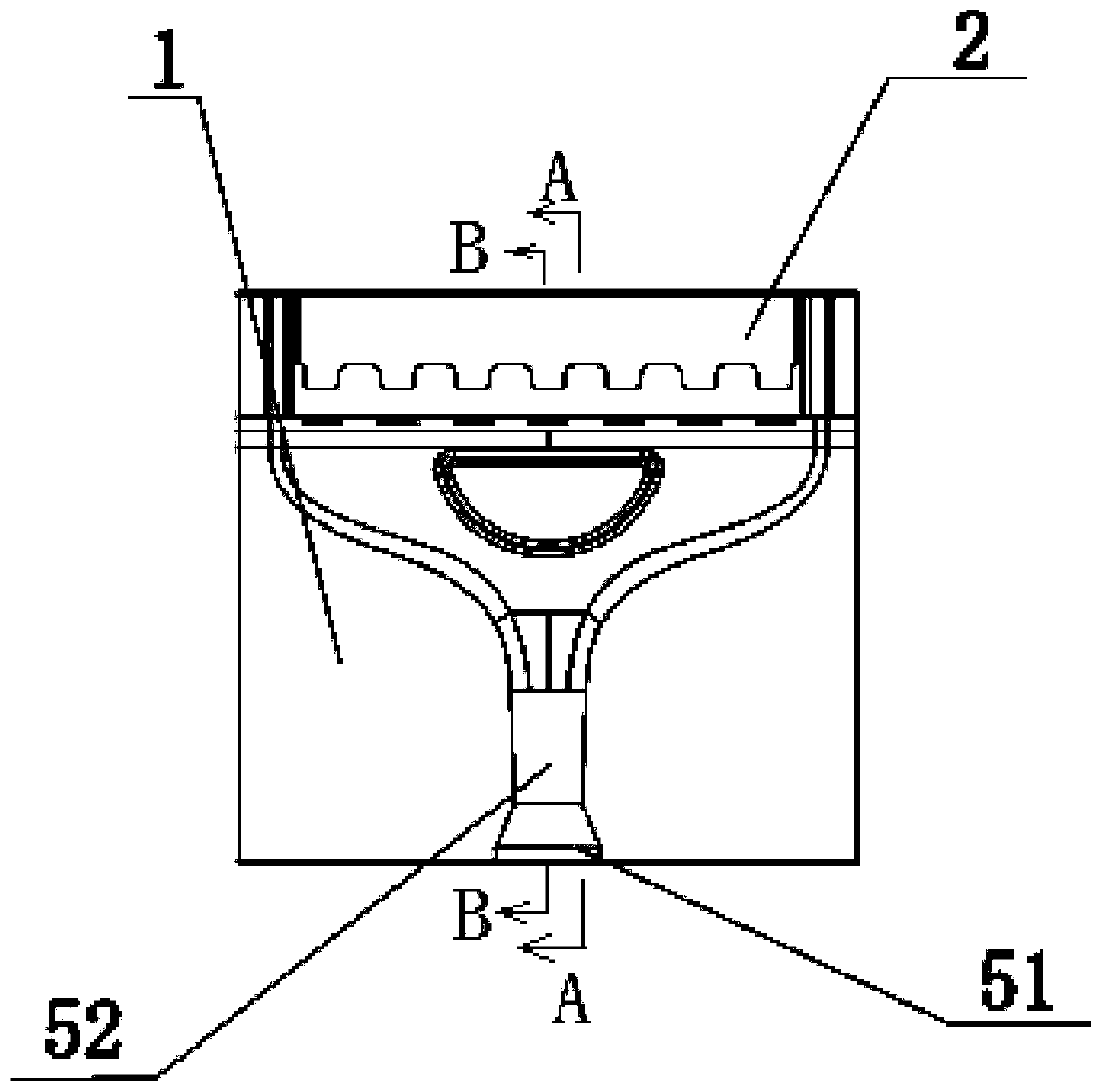

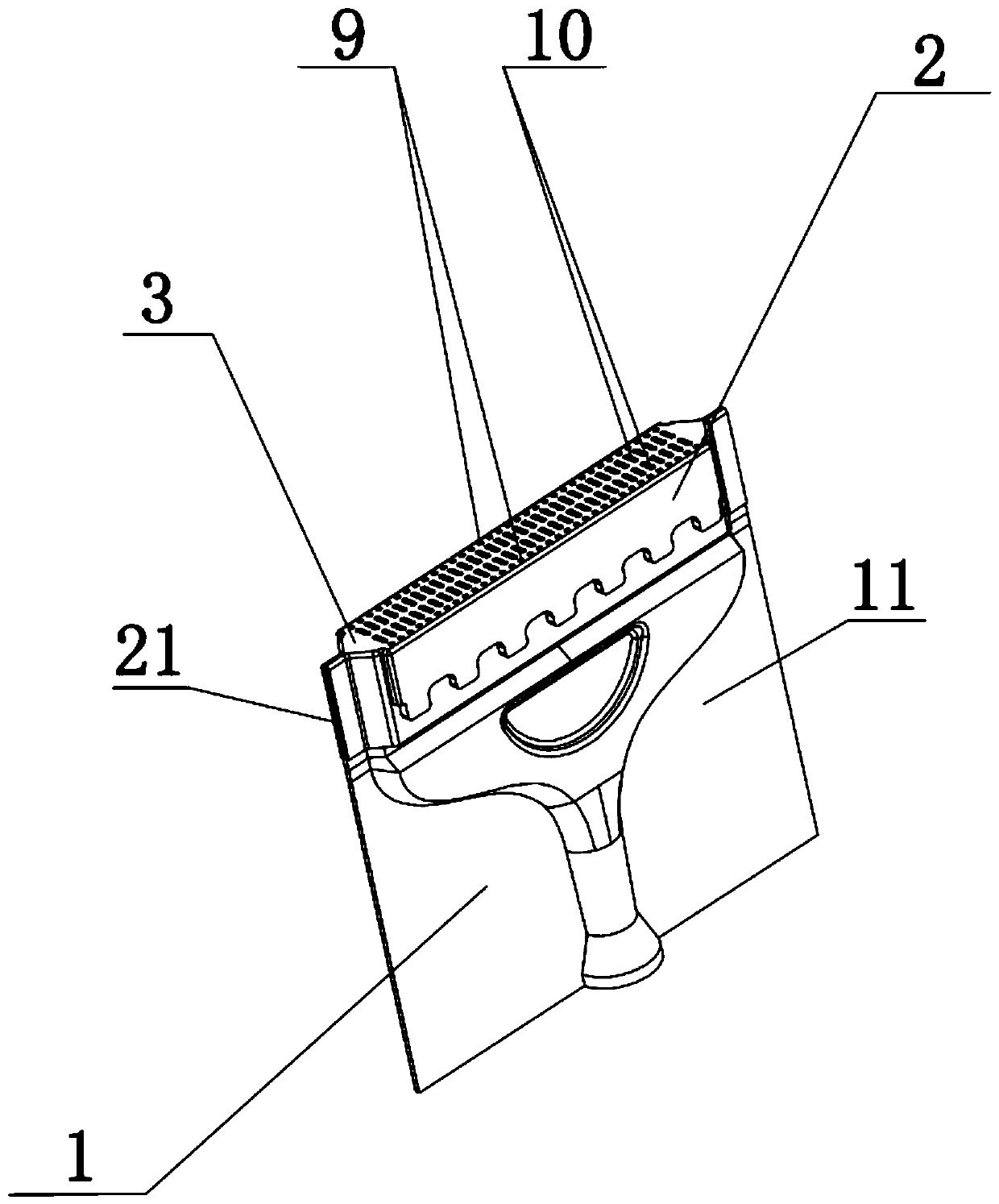

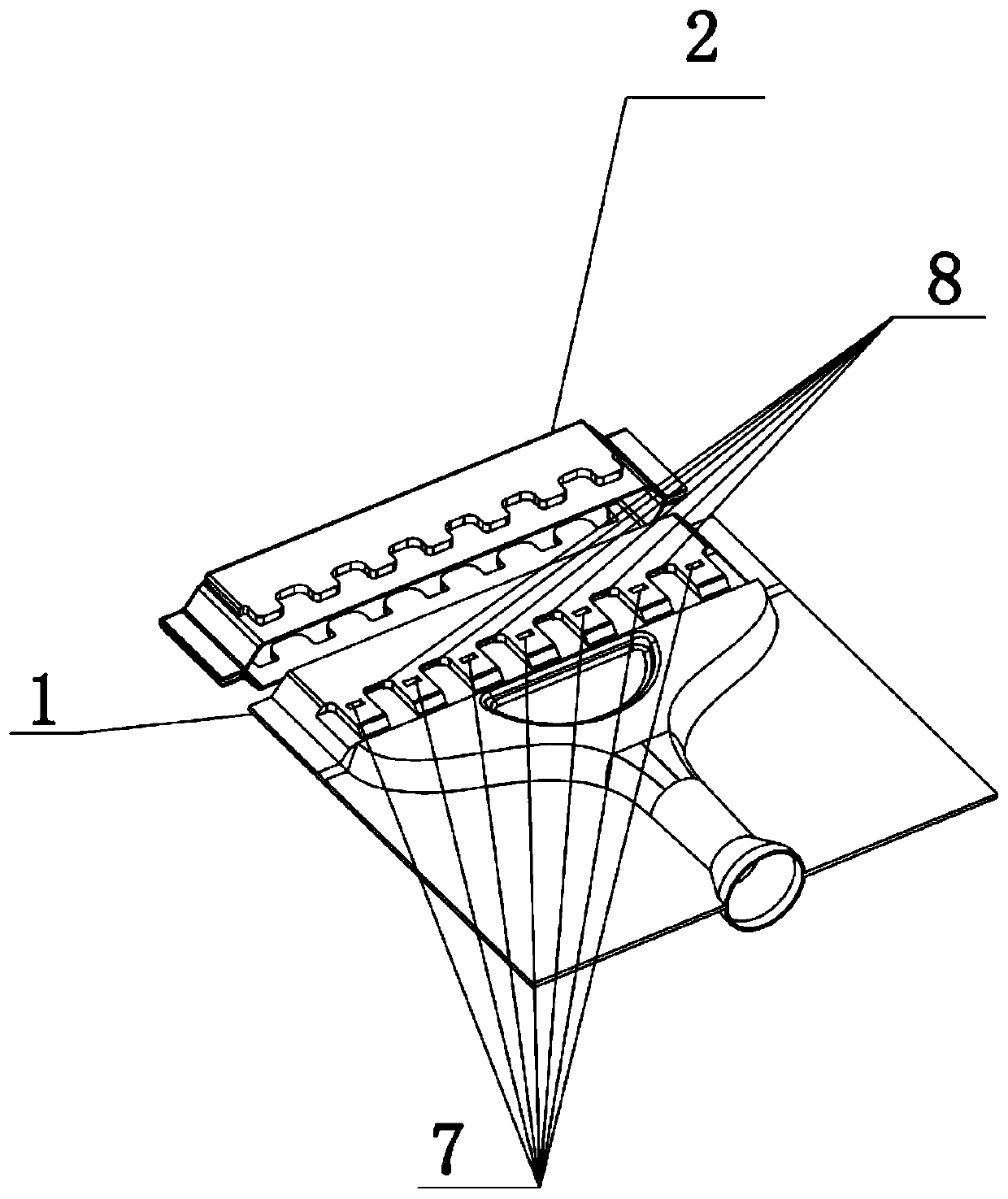

[0029] Such as Figure 1 to Figure 8As shown, a low nitrogen oxide burner includes an inner shell 1 and an outer shell 2 installed outside the inner shell 1, one end of the outer shell 2 is provided with a fire hole plate 3, and a dense flame is formed between the outer shell 2 and the inner shell 1 Channel 4; the inner shell 1 is formed with a premixed channel 5 and a thin flame channel 6 which communicate with each other, and the inner shell 1 is provided with a thick flame premixed gas inlet 7 which communicates with the premixed channel 5 and the thick flame channel 4, and the inner shell 1 A secondary air inlet 8 through which outside air enters into the light flame passage 6 is arranged on the top; a number of thick fire holes 9 connected to the thick flame passage 4 and a number of light fire holes 10 connected to the light flame passage 6 are arranged on the fire orifice plate 3; The premix channel 5 is vertically upward and forms a "T" shape with the fire orifice plat...

Embodiment 2

[0040] The difference from Example 1 is that, as Figure 8 As shown, one end of the shell 2 can also replace the fire hole plate 3 by installing a fire hole core 14. The fire hole core 14 is a structure formed by a number of stainless steel plates arranged at intervals. A gas channel is formed between several stainless steel plates and formed at the top Light fire hole 10, the top of thick flame passage 4 forms thick fire hole 9.

[0041] working principle:

[0042] The gas is injected into the injection section 51 of the premixing channel 5 at a certain pressure, and the air outside the burner is drawn into the premixing channel 5 and fully mixed in the mixing section 52 to become a premixed gas of gas and air, such as Figure 5 As shown, the premixed gas is divided into three gas paths, of which the left and right two gas paths enter the left and right thick flame passages 4 through the thick flame premixed gas inlet 7, and then burn in the thick flame hole 9 to form a thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com