Burner ring

A burner and fire cover technology, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve problems such as blockage, main fire hole flame separation, and inability to ensure stable combustion, etc., to achieve enhanced flame stabilization, stable flame stability, Achieve self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

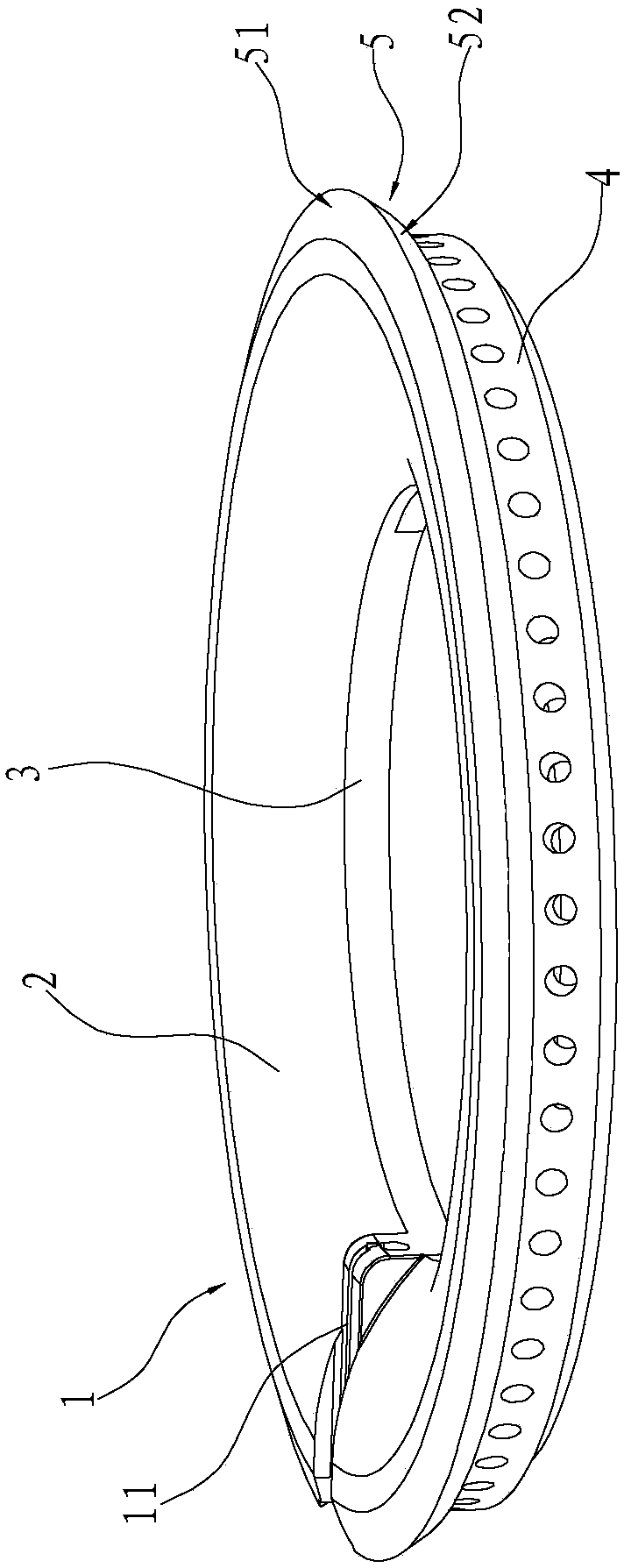

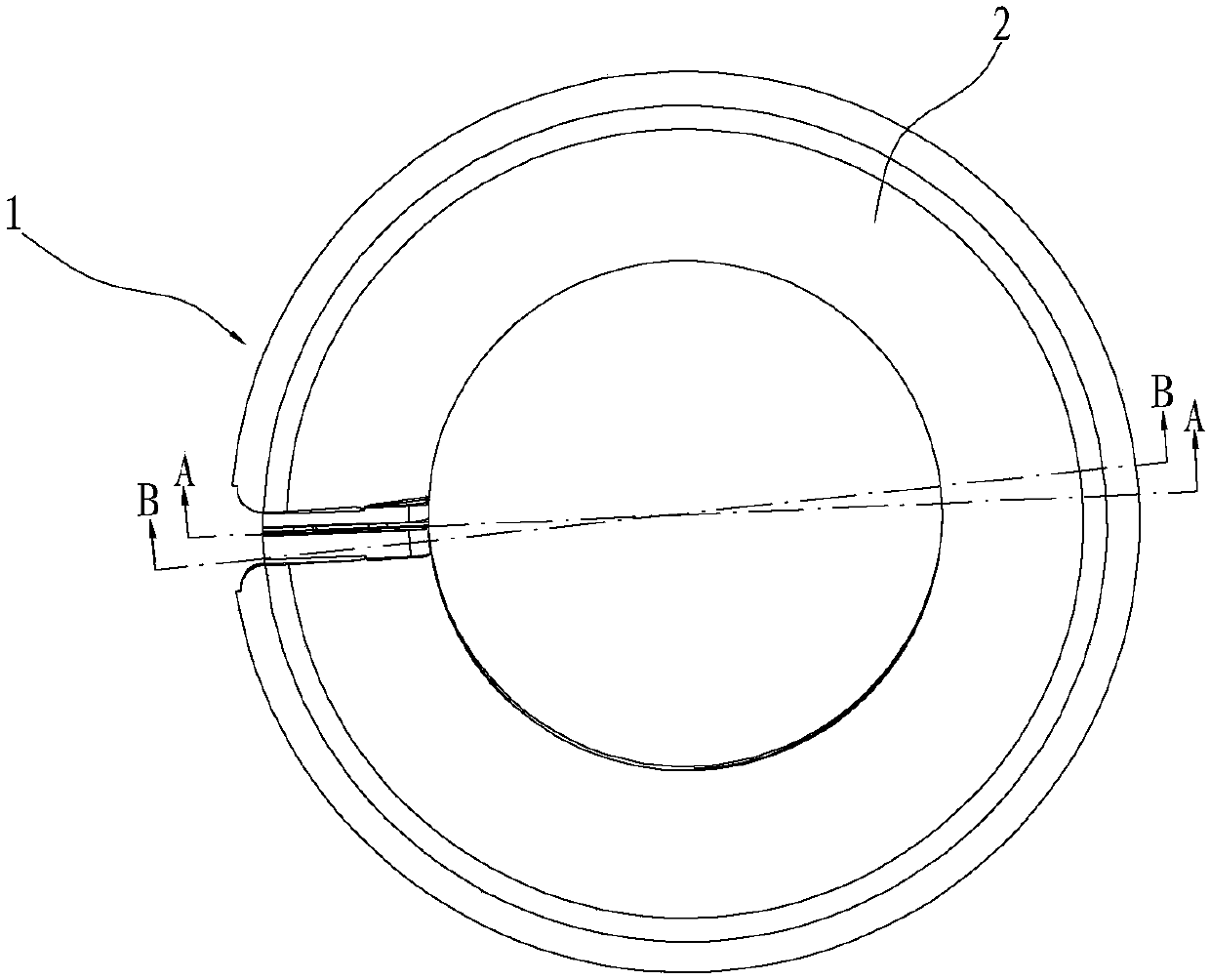

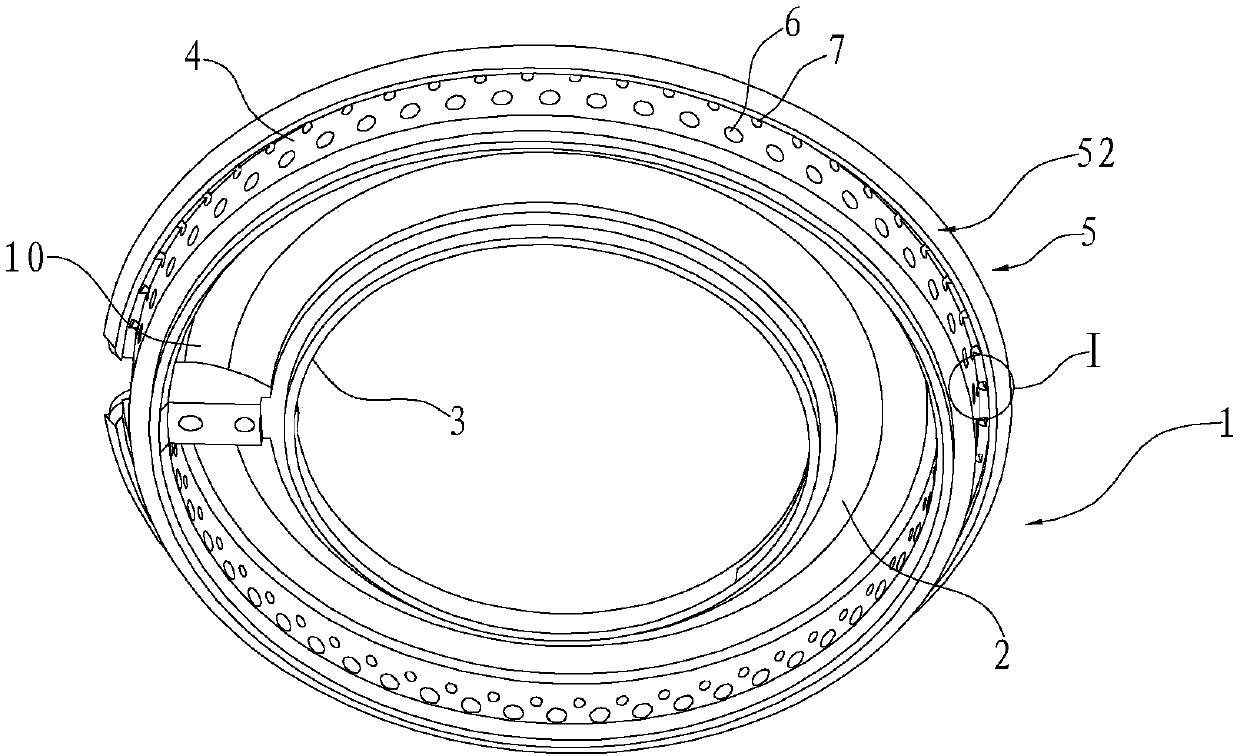

[0029] like Figures 1 to 6 As shown, a burner fire cover includes an annular fire cover body 1, the fire cover body 1 includes an annular top wall 2, inner and outer edges respectively extending vertically downward from the inner and outer edges of the top wall 2. The outer ring walls 3 and 4, wherein, the outer ring wall 4 is respectively provided with a fire outlet hole 6 and a flame stabilization hole 7 at intervals along the circumferential direction. In this embodiment, the burner fire cover is an outer ring fire cover, the holes of the fire outlet hole 6 and the flame stabilization hole 7 are inclined upward from the inside to the outside, and the hole channel of the fire outlet hole 6 and the hole channel of the flame stabilization hole 7 are parallel to each other. set up.

[0030] Further, the above-mentioned flame stabilization hole 7 is located above the fire outlet hole 6, and the flame stabilization hole 7 and the fire outlet hole 6 are arranged at intervals, so...

Embodiment 2

[0037] like Figures 7 to 9 As shown, what is different from Embodiment 1 is that in this embodiment, the inner side of the flame stabilizing eaves 5 is provided with a baffle wall 8 that can laterally separate the inner cavity of the flame stabilizing groove 50 along the circumferential direction. The adjacent baffle walls 8 The gaps therebetween form second diffuser chambers 9 , and each second diffuser chamber 9 corresponds to the flame stabilization holes 7 one-to-one. By arranging the second diffuser chamber 9, the airflow flowing out of the flame stabilization hole 7 can be diffused and reduced in speed, thereby further enhancing its flame stabilization effect. In this embodiment, the above-mentioned baffle wall 8 is arranged between the outer ring wall 4 and the flame stabilizing eaves 5 , that is, one end of the baffle wall 8 is fixed to the outer ring wall 4 , and the other end is fixed to the flame stabilizing eaves 5 .

[0038] Further, the above-mentioned baffle w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com