Ship coating defect knowledge acquisition method based on PCA-rough set

A knowledge acquisition, rough set technology, applied in jetting devices, special data processing applications, instruments, etc., can solve the problems of data doping noise and interference terms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

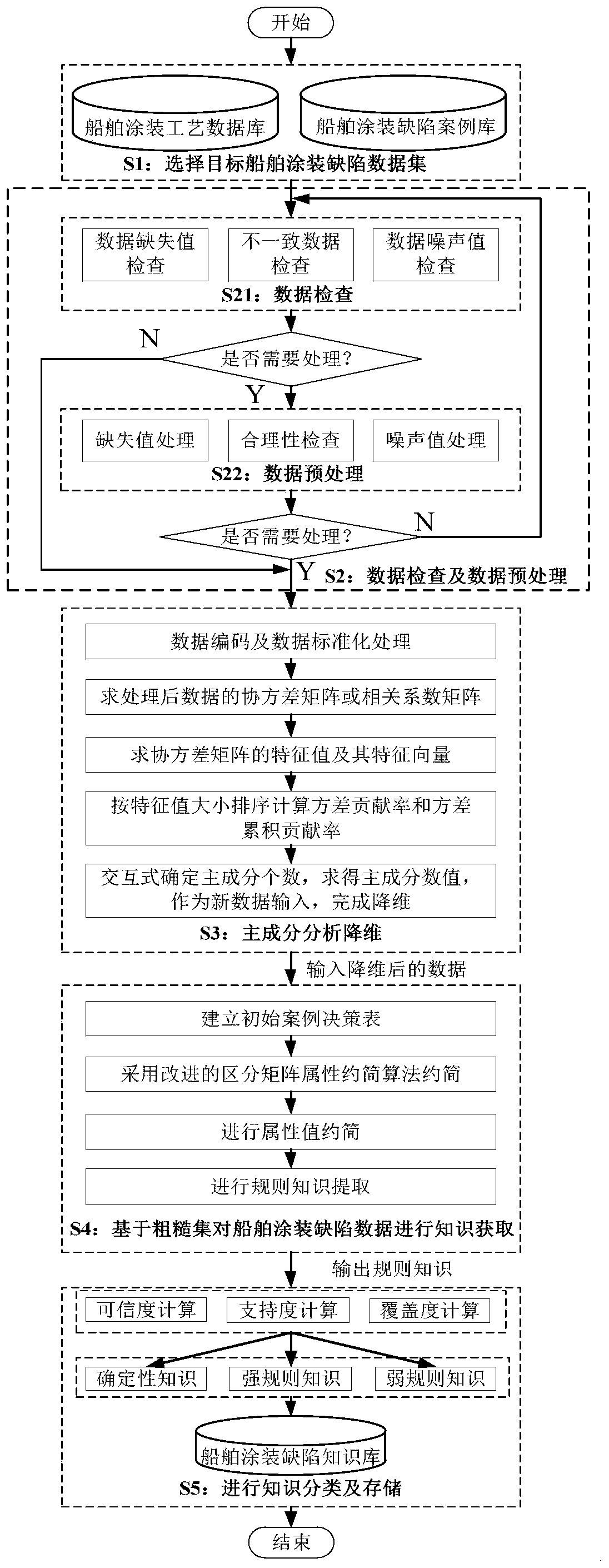

[0040] Such as figure 1 The method for acquiring knowledge of ship coating defects based on PCA-rough sets includes the following steps:

[0041] S1: Select the target dataset:

[0042] The target data set is selected from the ship coating process database and the ship coating defect case library. The target data set includes attribute information, parameter information and environmental information. Among them, the attribute information includes painting area, painting area, surface roughness, Rust level, coating method, coating equipment, etc.; parameter information includes paint viscosity, aerodynamic force, spray distance, paint transfer rate, etc.; environmental information includes air velocity, relative humidity, air temperature, etc.

[0043] S2: Data inspection and data preprocessing:

[0044] Check and preprocess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com