Italian ice cream and making method thereof

An ice cream, Italian-style technology, applied in the fields of frozen desserts, food science, applications, etc., can solve the problems that consumers do not like, the creaminess and sweetness are enhanced, and achieve the effect of enhancing the value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

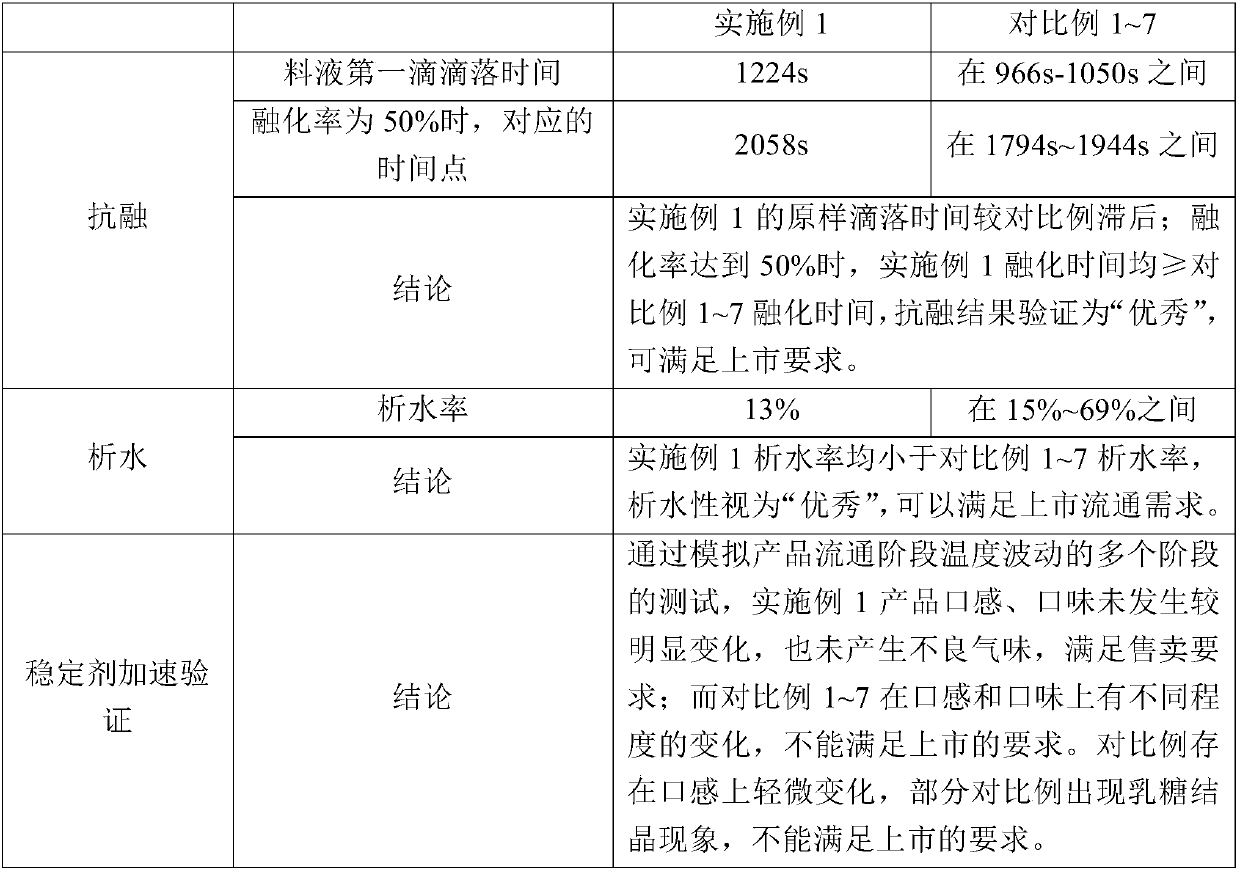

Examples

Embodiment 1

[0029] Embodiment 1 A kind of Italian ice cream

[0030] 1. Preparation of raw materials:

[0031] Based on the total weight percentage of raw materials as 100%, according to 8% white sugar, 8% skimmed milk powder, 15% glucose syrup, 2% polydextrose, 3% isomaltooligosaccharide, 7% anhydrous cream, 5% coconut oil, 2% whey protein powder, 1% maltodextrin, 0.25% locust bean gum, 0.2% mono- and diglyceride fatty acid lipids, the balance is water, and each raw material is weighed.

[0032] 2. Preparation of gelato

[0033] 1) Ingredients: mixing the above raw materials to obtain a mixture;

[0034] 2) Homogenization: Homogenize the above mixture at 72°C and 15MPa to obtain the base material;

[0035] 3) Sterilization: Sterilize the base material at 85°C for 30s;

[0036] 4) Cooling: cooling the sterilized base material to 5°C;

[0037] 5) Congealing: Congeal the cooled base material through a freezer, the discharge temperature is -6°C, and the expansion rate is controlled at 2...

Embodiment 2

[0042] Embodiment 2 A kind of Italian ice cream

[0043] 1. Preparation of raw materials:

[0044] Based on the total weight percentage of raw materials as 100%, according to 6% white sugar, 10% skimmed milk powder, 15% glucose syrup, 1% polydextrose, 4% isomaltooligosaccharide, 10% coconut oil, 2% whey protein powder , 1% maltodextrin, 0.1% locust bean gum, 0.3% mono- and diglyceride fatty acid lipids, the balance being water, and weighing each raw material.

[0045] 2. Preparation of gelato

[0046] 1) Ingredients: mixing the above raw materials to obtain a mixture;

[0047] 2) Homogenization: Homogenize the above mixture at 70°C and 18MPa to obtain the base material;

[0048] 3) Sterilization: Sterilize the base material at 80°C for 30s;

[0049] 4) Cooling: cooling the sterilized base material to 2°C;

[0050] 5) Congealing: Congeal the cooled base material through a freezer, the discharge temperature is -5°C, and the expansion rate is controlled at 20%;

[0051] 6) ...

Embodiment 3

[0055] Embodiment 3 A kind of Italian ice cream

[0056] 1. Preparation of raw materials

[0057] Based on the total weight percentage of raw materials as 100%, according to 12% white sugar, 8% whole milk powder, 2% skimmed milk powder, 10% maltose syrup, 3% polydextrose, 1% maltooligosaccharide, 8% anhydrous butter , 3% whey protein powder, 1% maltodextrin, 0.3% locust bean gum, 0.1% mono- and diglyceride fatty acid lipids, and the balance is water, and each raw material is weighed.

[0058] 2. Preparation of gelato

[0059] 1) Ingredients: mixing the above raw materials to obtain a mixture;

[0060] 2) Homogenization: Homogenize the above mixture at 75°C and 13MPa to obtain the base material;

[0061] 3) Sterilization: sterilize the base material at 90°C for 30s;

[0062] 4) Cooling: cooling the sterilized base material to 10°C;

[0063] 5) Congealing: Congeal the cooled base material through a freezer, the discharge temperature is -6.5°C, and the expansion rate is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com