Intelligent surgical postoperative disinfection device

A sterilization device and surgical technique, applied in the directions of sterilization, surgery, medical science, etc., can solve the problems of unintelligent energy saving, low sterilization effect of soaking sterilization method, poor working efficiency, etc., and achieve reasonable structural design, intelligent control, energy saving and high efficiency , the effect of facilitating the collection of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

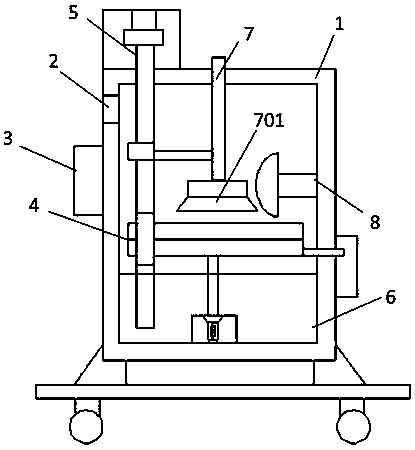

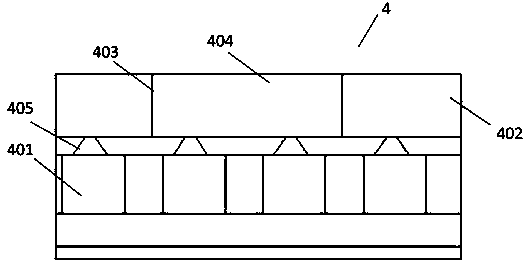

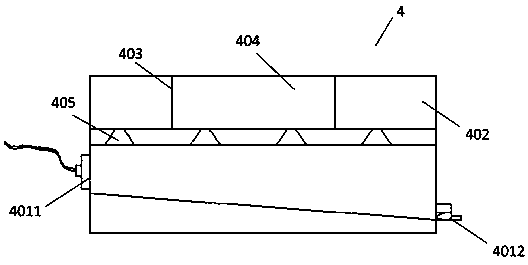

[0022] An intelligent postoperative disinfection device for surgical operations, comprising a housing 1, a placement opening 2 and a controller 3 arranged on the front face of the housing 1, characterized in that the disinfection device also includes a disinfection tray 4 connected to the disinfection tray 4 The lifting device 5, the soaking pool 6, the spraying equipment 7 and the drying device 8, the controller 3 can control the disinfection tray 4 to eject from the placement opening 2, the disinfection tray 4 is double-layered, with several The lower layer composed of ventilation ducts 401 arranged parallel to each other and the placement layer 402 correspondingly arranged on the ventilation duct 401, the placement layer 402 is provided with a partition 403, the partition 403 and the four sides of the placement layer 402 The surrounding walls together form a surgical instrument placement space 404, and the placement layer 402 is also provided with a number of circular throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com