Fabricated integrated large plate

An integrated and integrated technology, applied in building components, buildings, building structures, etc., can solve the problems of weakened strength of composite wall panels, complicated grouting process, and no technical solutions for opening or opening. Improve the construction efficiency and construction quality, simplify the assembly process, and simplify the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

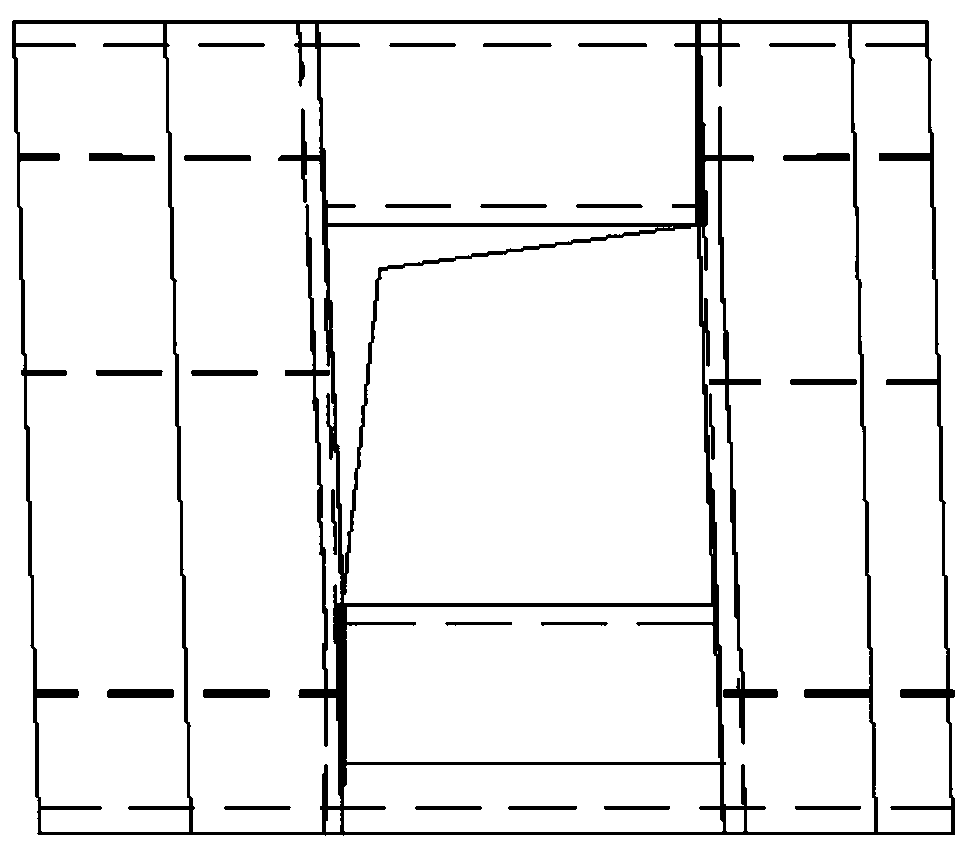

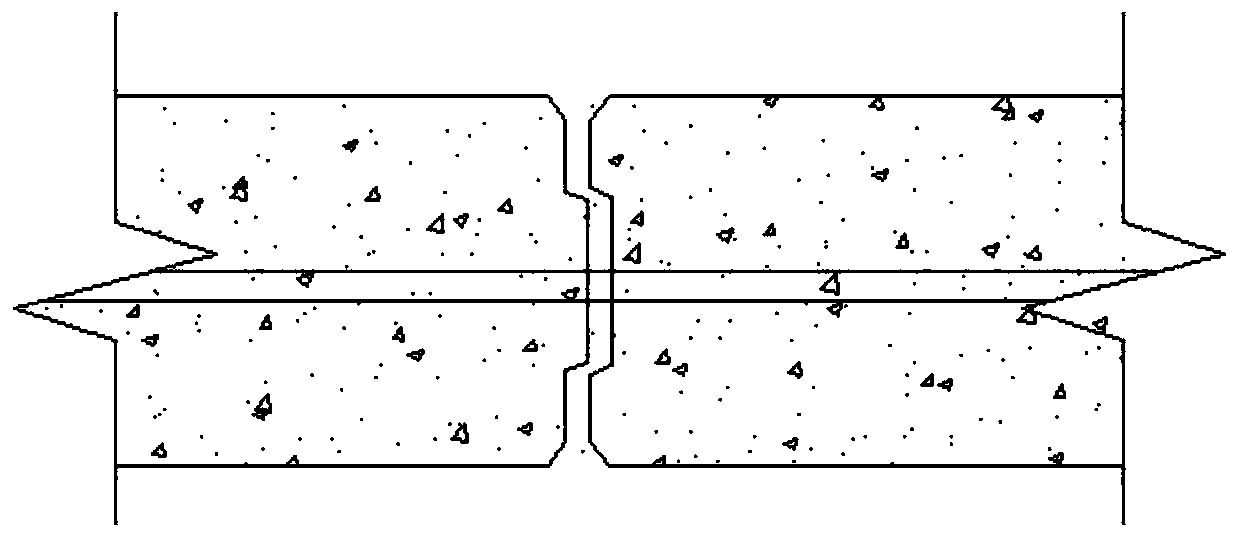

[0094] Such as Figure 6 The shown assembled integral large slab includes a plurality of vertical prefabricated slabs 1 arranged vertically, and mechanical anchoring devices 17 are provided between the vertical prefabricated slabs 1 through the first tie bar 14 or the second tie bar. Ribs 15 are connected together. The setting of No. 1 tie bar 14 or No. 2 tie bar 15 can be connected with no less than 2 prefabricated slabs 1 that are closely connected as a group with No. Only connect to each other with one No. 1 tie rod 14. The mechanical anchoring devices 17 at both ends of the No. 1 tie bar 14 are anchored by nuts with backing plates. The setting method of the mechanical anchoring device 17 located in the prefabricated slab 1 can refer to the method of built-in anchors in the autoclaved aerated concrete panel, which is a prior art and will not be elaborated here. The prefabricated slab 1 is an aerated concrete or ceramsite concrete slab or a reinforced concrete slab. Adhe...

Embodiment 2

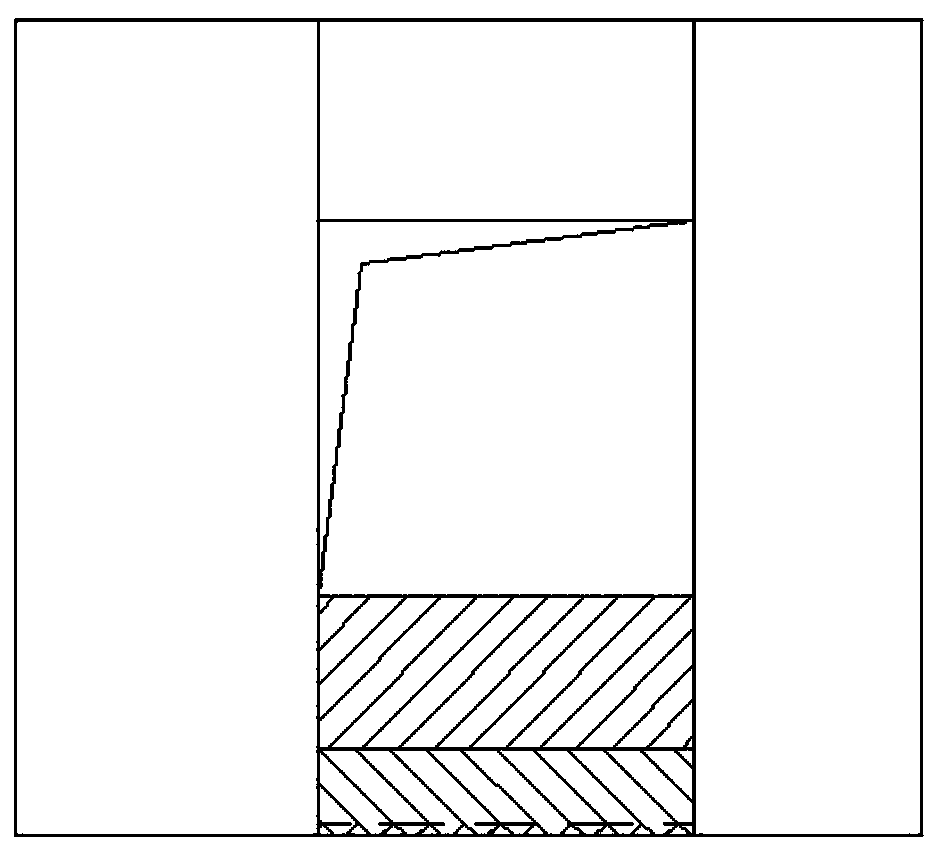

[0096] Such as Figure 7 The assembled integral large slab shown includes a plurality of vertically arranged vertical prefabricated panels 1 , and the vertical prefabricated panels 1 are connected together by long tie bars 4 . The full-length tie bar 4 is a steel bar 4 arranged in a reserved hole parallel to the width direction of the prefabricated panel 1, and the reserved hole is filled with high-strength grouting material (adhesive); the prefabricated Board 1 is aerated concrete or ceramsite concrete board or reinforced concrete board. Adhesive bonding is provided between two adjacent prefabricated panels 1 that are closely connected. The binder is mortar or glue or building cementitious material.

Embodiment 3

[0098] Such as Figure 8 The assembled integral large slab shown includes a plurality of vertical prefabricated panels 1 arranged vertically, and the vertical prefabricated panels 1 are connected together by No. 3 tie bars 16 . The No. 3 tie bar 16 is a carbon fiber cloth arranged on the outer surface of the prefabricated panel 1 and bonded with the prefabricated panel 1 with structural glue (adhesive). The prefabricated slab 1 is an aerated concrete or ceramsite concrete slab or a reinforced concrete slab. Adhesive bonding is provided between two adjacent prefabricated panels 1 that are closely connected. The binder is mortar or glue or building cementitious material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com