Prefabricated Prestressed Steel Tube Concrete Column and Its Construction Method

A technology of steel pipe concrete columns and construction methods, applied in the direction of columns, pillars, pier columns, etc., to achieve the effect of improving compressive strength, simple structure, and realizing assembly construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

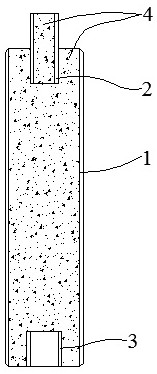

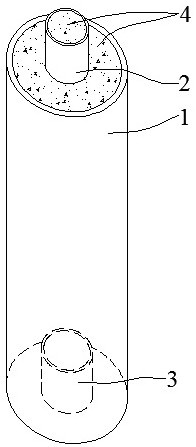

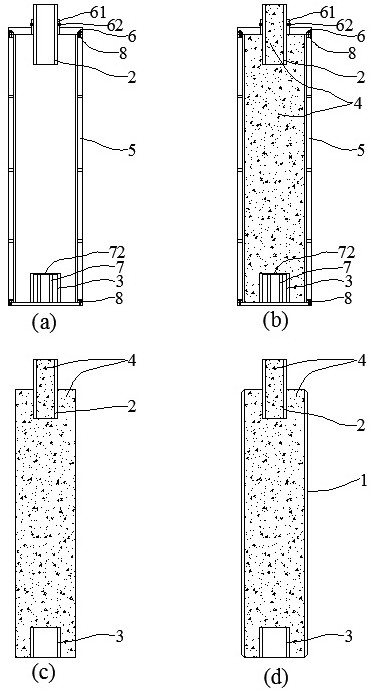

[0018] Such as Figure 1-2 As shown, a prefabricated prestressed steel pipe concrete column is composed of outer steel pipe (1), upper steel pipe (2), lower steel pipe (3) and concrete (4); outer steel pipe (1), upper steel pipe (2) and lower The steel pipes (3) are all round steel pipes, the axes of the outer steel pipe (1), the upper steel pipe (2) and the lower steel pipe (3) coincide; the upper steel pipe (2) is located on the top of the outer steel pipe (1), and one end extends out of the outer steel pipe (1 ), the length protruding out of the outer steel pipe (1) is not less than half of the inner diameter of the outer steel pipe (1), the length of the upper steel pipe (2) extending into the outer steel pipe (1) is equal to the protruding length; the lower steel pipe (3) is located in the outer steel pipe (1) ), does not protrude from the outer steel pipe (1), the inner diameter of the lower steel pipe (3) is equal to the outer diameter of the upper steel pipe (2), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com